Ceramic and glass reinforced plastic composite tube and preparing method thereof

A composite pipe, glass fiber reinforced plastic technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of difficult to make large-sized products, limited application of glass fiber reinforced plastic pipes, poor corrosion resistance and wear resistance, etc. It is easy to implement and light in weight. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment.

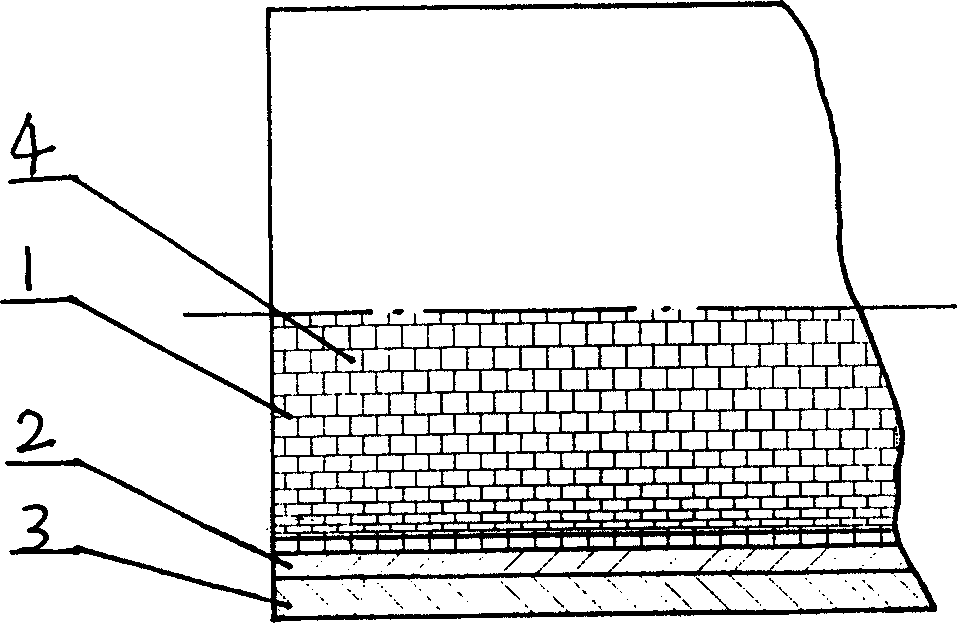

[0025] Such as figure 1 As shown, the ceramic and FRP composite pipes of the present invention are composed of three layers of ceramic inner layer 1, resin intermediate connection layer 2 and FRP outer layer 3 respectively. The ceramic inner layer is formed by splicing a plurality of ceramic blocks 4, and the splicing seams of the ceramic blocks are misplaced.

[0026] The specific preparation methods are respectively exemplified as follows:

[0027] Example 1. Using 10mm×10mm×4mm 92% alumina ceramic sheet as wear-resistant and corrosion-resistant ceramic material, alkali-free glass fiber as FRP reinforcement material, unsaturated polyester resin as FRP matrix, unsaturated polyester resin Ester resin is the material of the intermediate connection layer. Process the steel pipe into a core with a diameter of 150 mm and a length of 3.1 meters. Paste and fix the ceramic sheet on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com