Process for preparing silver/polypyrrole composite nano materials

A technology for composite nanomaterials and polypyrrole, which is applied in the field of preparing silver/polypyrrole composite nanomaterials, can solve the problem of high cost, and achieve the effects of low production cost and low reaction environment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

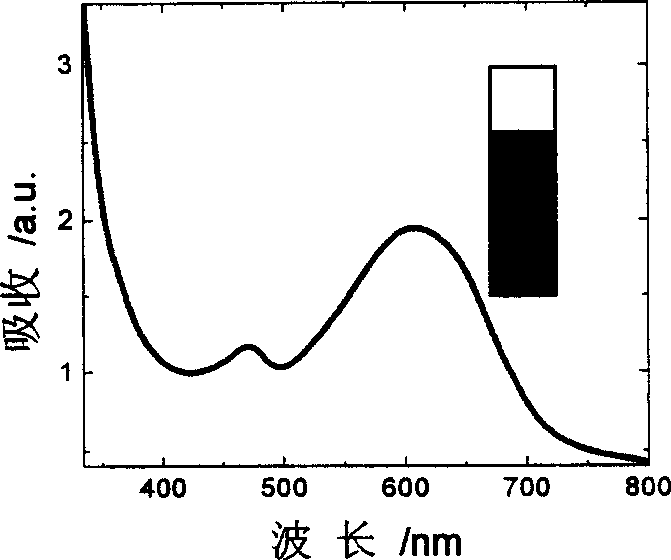

[0024] As mentioned above, take 360mg of silver nitrate and 0.2ml of pyrrole and dissolve them in 1ml of DMF respectively, then mix them and place them in the dark for reaction. After more than 24 hours of reaction, observe that the color of the solution turns blue, and measure its absorption spectrum at 620nm A strong absorption peak was obtained nearby, indicating the formation of silver / polypyrrole composite sol. figure 1 The absorption spectrum curve and color diagram of the silver / polypyrrole composite sol obtained by femtosecond laser irradiation are given in . The sol is stable for several months when stored in the refrigerator.

Embodiment 2

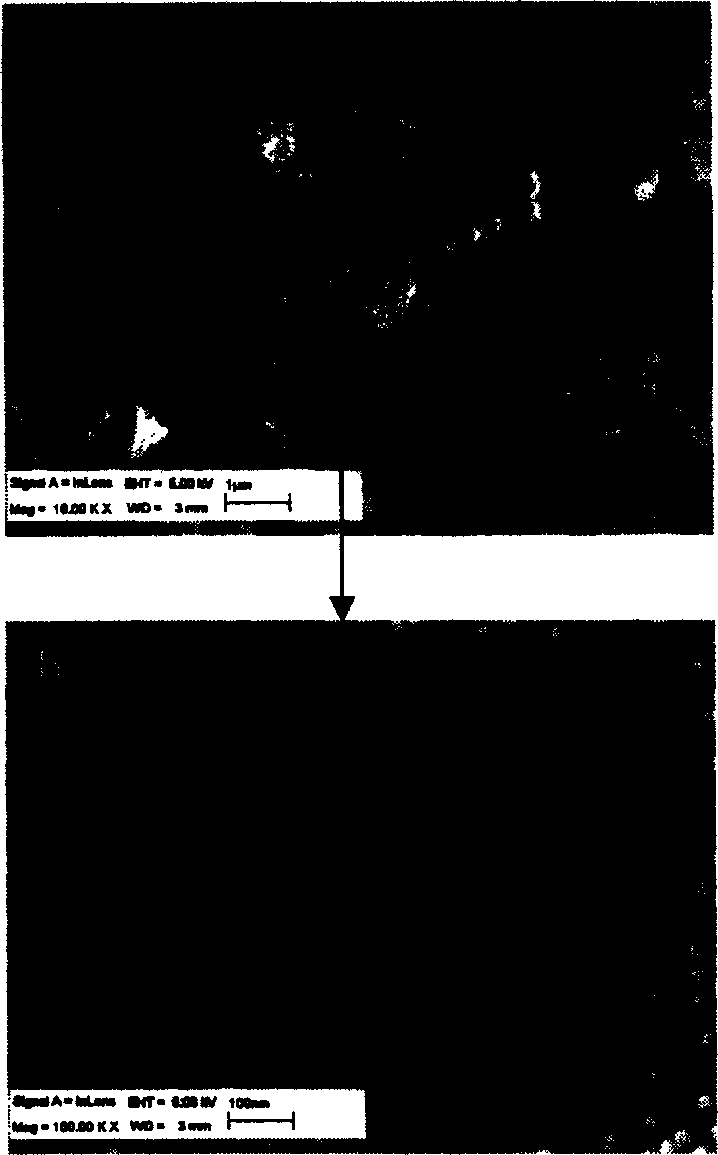

[0026] As described above, take 360 mg of silver nitrate and 0.2 ml of pyrrole and dissolve them in 1 ml of DMF solution and mix them, and then irradiate them under light sources such as ultra-short pulse lasers such as ultraviolet light or femtosecond laser until the color of the solution turns purple, and then After aging the solution for about 6 hours, a blue sol can be obtained, and its absorption spectrum has an absorption peak near 620 nm. figure 2 The morphology of the silver / polypyrrole composite sol prepared by femtosecond laser irradiation is given, figure 2 a is a FESEM photo enlarged by 10,000×, figure 2 b is a FESEM image enlarged at 100,000×. The sol is stable for several months when stored in the refrigerator.

Embodiment 3

[0028] As described above, take 3.6g of silver nitrate and 0.5ml of pyrrole and dissolve them in 1ml of DMF respectively, then mix them and place them under dark conditions for reaction. After about 15 hours, observe that the color of the solution turns blue, and measure its absorption spectrum at A strong absorption peak was obtained near 620nm, indicating the formation of silver / polypyrrole composite sol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com