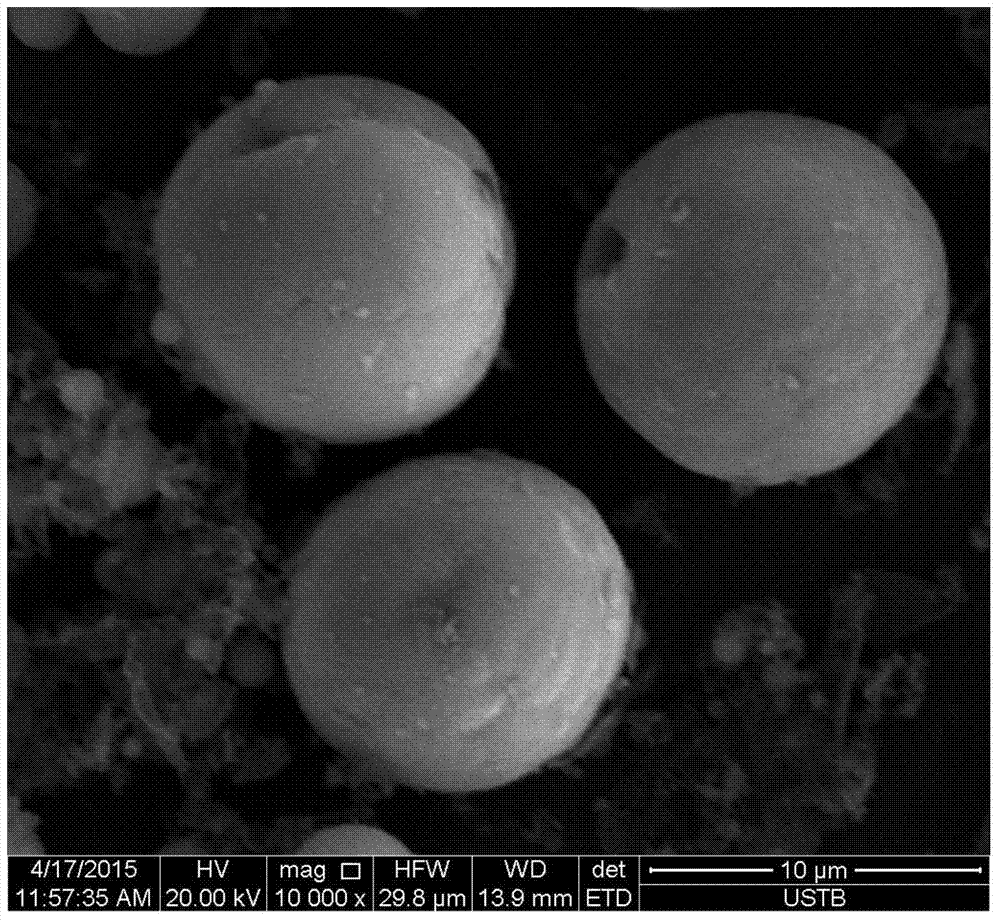

A method for preparing alumina microsphere powder by liquid-phase cathode plasma electrolysis

A liquid-phase plasma, alumina technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of uneven particle size distribution of alumina microspheres, complex process, high cost, and avoid easy agglomeration and grain growth. , The preparation process is simple and the cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: adopt titanium alloy as cathode material

[0020] Pulse power supply is used, the frequency is 500Hz, and the duty ratio is 60%. The platinum sheet is used as the anode; the titanium alloy is used as the cathode; h. The arcing voltage is 120V, and then gradually rises to 170V. Then the electrolyte was allowed to stand still, and turbidity appeared at the bottom, passed through a centrifuge (4000 rpm), and centrifuged three times with distilled water and alcohol respectively. Afterwards, it was kept at 105° C. in a blast drying oven, and dried to obtain a powder.

Embodiment 2

[0021] Embodiment 2: Adopt aluminum alloy as cathode material

[0022] Using pulse power supply, frequency 500Hz, duty cycle 60%; platinum sheet as anode; aluminum alloy as cathode; electrolyte is 300g / L aluminum nitrate nonahydrate, 25g / L polyethylene glycol, plasma electrolysis time is 2~ 2.5h. The arcing voltage is 100V, and then gradually rises to 170V. A coated titanium alloy and an electrolyte are obtained. Among them, the electrolyte was left standing, and turbidity appeared at the bottom. After high-speed centrifugation, it was centrifuged three times with distilled water and alcohol respectively. Afterwards, it was kept at 105° C. in a blast drying oven, and dried to obtain a powder.

Embodiment 3

[0023] Example 3: Changing the electrolyte concentration

[0024] Using pulse power supply, frequency 500Hz, duty cycle 60%; platinum sheet as anode; titanium alloy as cathode; electrolyte solution is 150g / L aluminum nitrate nonahydrate, 15g / L polyethylene glycol, and the plasma electrolysis time is 3~ 3.5h. The arcing voltage is 120V, and then gradually rises to 150V. Then the electrolyte was left to stand, passed through a centrifuge (4000 rpm), and centrifuged three times with distilled water and alcohol respectively. After drying, powder is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com