Self locking, breaking up and destructing safety syringe

A safe, syringe technology, applied in the field of medical devices, can solve the problems of difficult to achieve blockage, cannot be used normally, and difficult to process, and achieve the effects of reducing residual flow, good effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

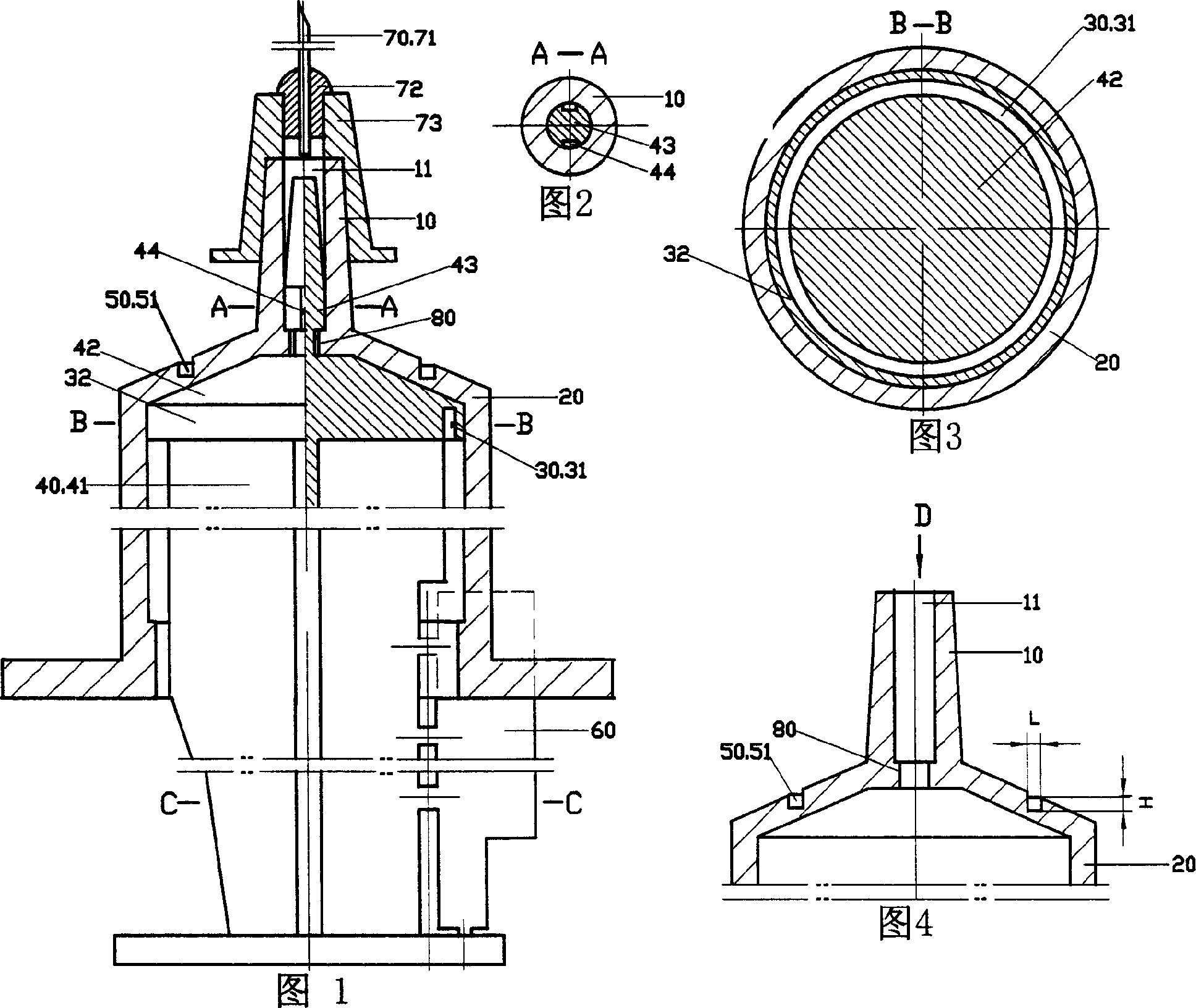

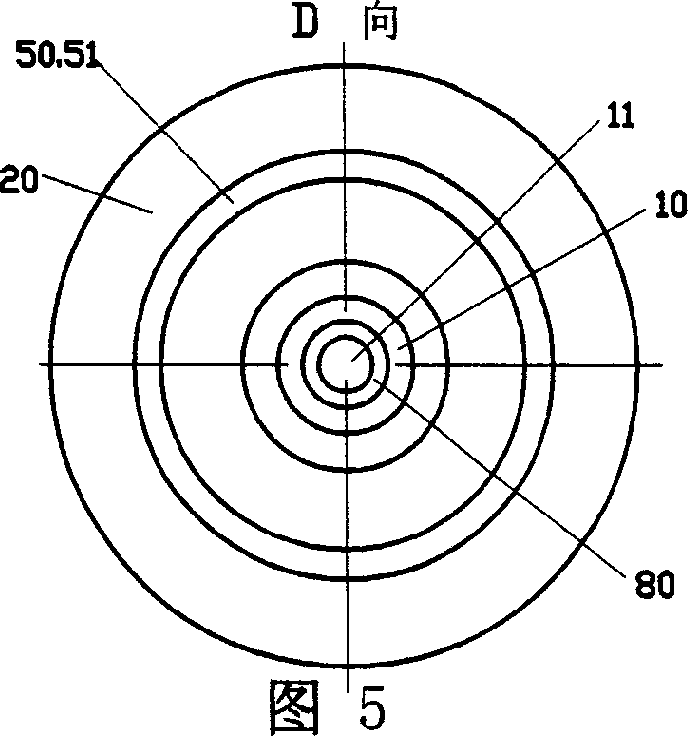

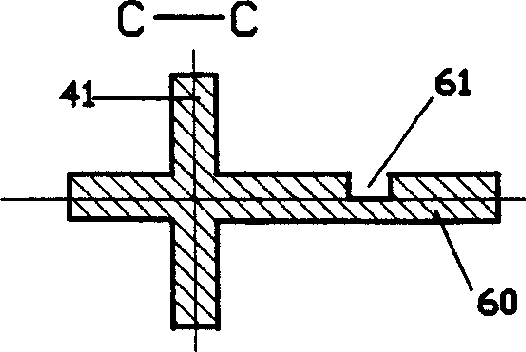

[0070] See Fig. 1 to Fig. 7, the material used in the syringe of this embodiment complies with the national standard. The injector of the present embodiment comprises cone 10, overcoat 20 and core rod 40; Cone head 10 has cone hole 11, and cone 10 and overcoat 20 are one piece; Core rod 40 has shaft 41 and top 42; Syringe also has Self-locking boss 80; a breakable structure 50 is provided on the jacket 20 or a breakable structure 50 is provided on the core rod 40; an elastic sealing structure 30 is provided on the top 42 of the core rod 40; see Fig. 1 and Fig. 1 3. The elastic sealing structure 30 of the top 42 of the core rod 40 is composed of an elastic groove 31 and a sealing ring 32. The elastic sealing structure 30 is integrated with the top 42 of the core rod 40; the outer wall of the sealing ring 32 of the elastic sealing structure 30 can be connected with The inner wall of the overcoat 20 is matched, and the outer diameter of the outer wall of the sealing ring 32 and t...

Embodiment 2

[0073] See Fig. 8 and Fig. 9, the use effect of the elastic sealing structure 30 of the syringe of this embodiment is basically the same as that of Embodiment 1, and the opening direction of the elastic groove 31 is upward; Groove 51; present embodiment is applicable to the syringe of specification above 5 milliliters; See Fig. 8, be provided with anti-poking slope 45 on protruding rod 43, can prevent that the parts that have been by self-locking are poked off. All the other are identical with embodiment 1.

Embodiment 3

[0075] Referring to Fig. 10 to Fig. 12, this embodiment is more suitable for syringes with specifications below 5 milliliters. The breakable structure 50 on the upper part of the overcoat 20 of the syringe in this embodiment is an unclosed arc-shaped groove 51; the number of the arc-shaped groove 51 is 1, and the arc of the arc-shaped groove 51 is 285°; Change the width of arc-shaped groove 51, the depth of arc-shaped groove 51, the quantity of arc-shaped groove 51, the radian of arc-shaped groove 51, thereby can change the size of the active force that makes breakable structure 50 break and disengage; See As shown in Fig. 10 and Fig. 12, an elastic groove 46 is provided on the protruding rod 43; the protruding rod 43 does not have an axial liquid guide groove 44; after the liquid medicine injection is completed, the last liquid medicine enters the cone head through the elastic groove 46 on the protruding rod 43 In the hole 11, to reduce the residual flow of the liquid medicin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com