Microchannel plate-fin type water vapour reforming reactor for hydrogen production

A microchannel plate, reforming hydrogen production technology, applied in hydrogen, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of uneven temperature distribution in the reactor, achieve better heat transfer effect, high heat transfer efficiency, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

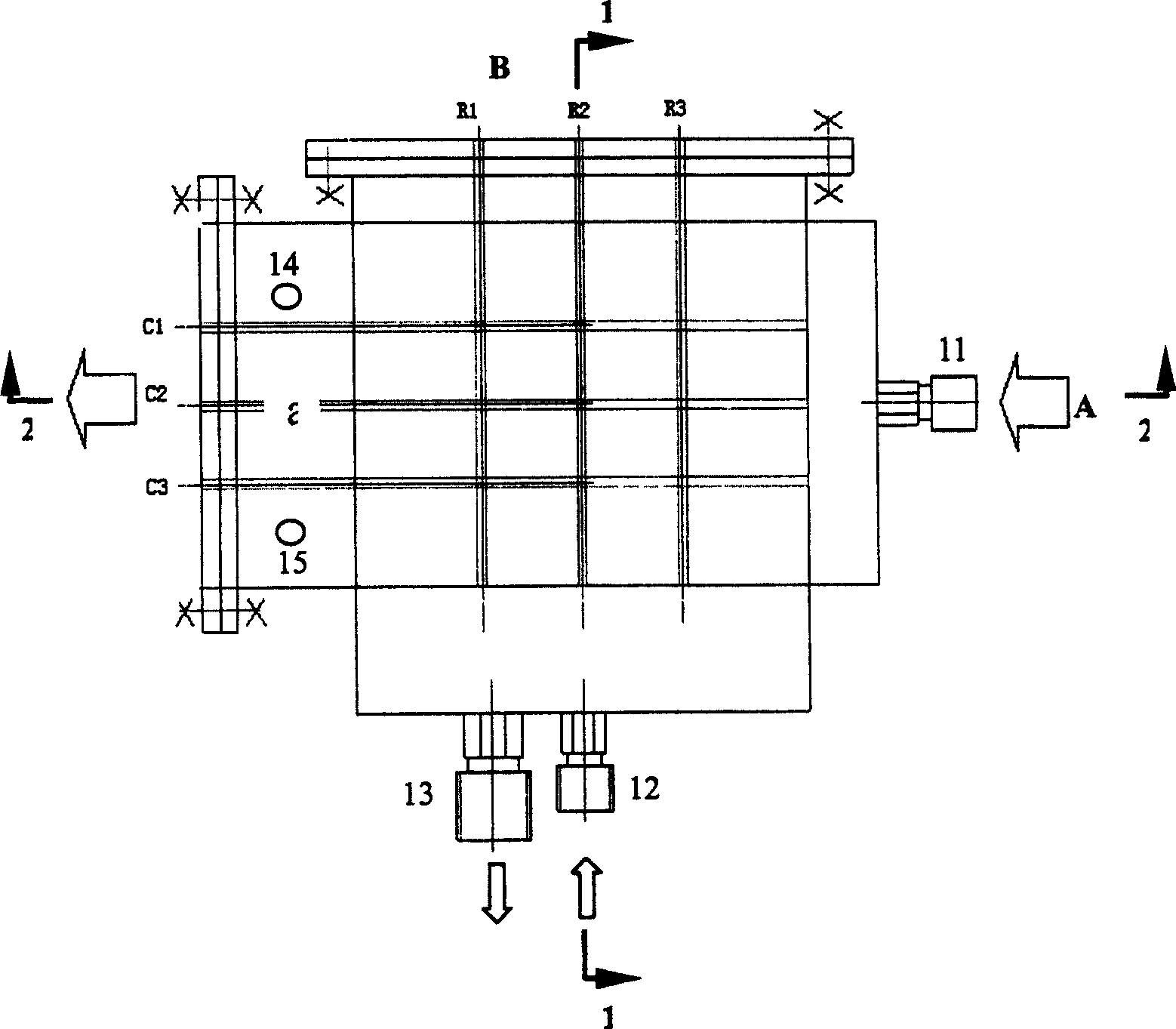

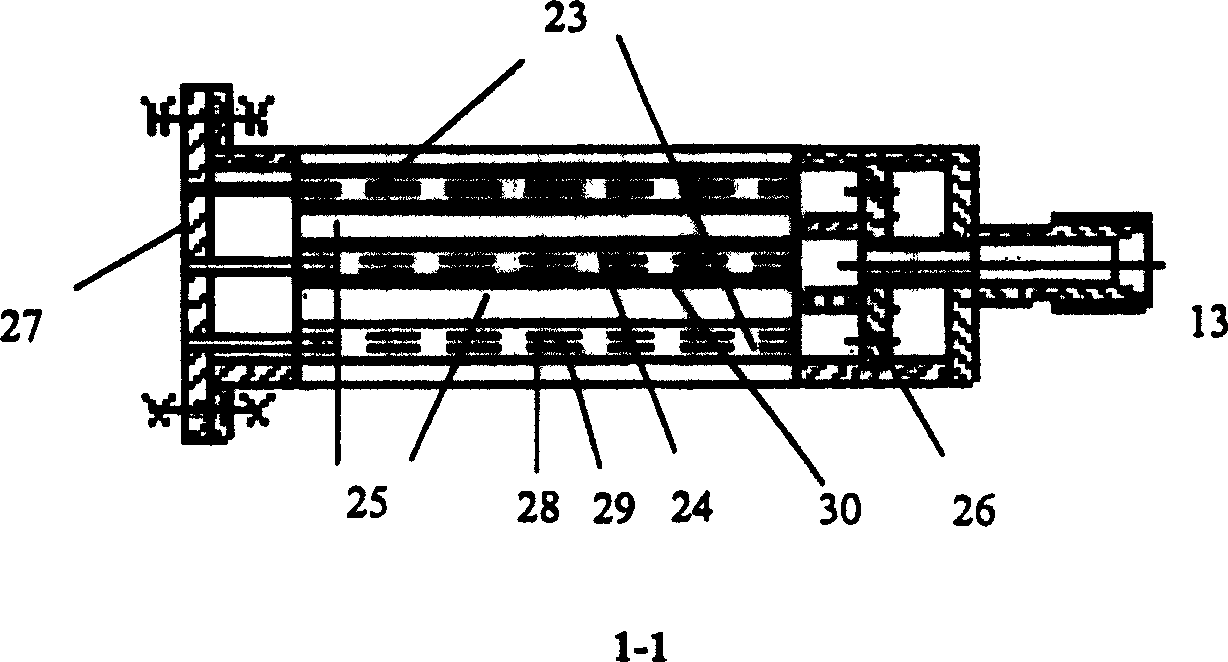

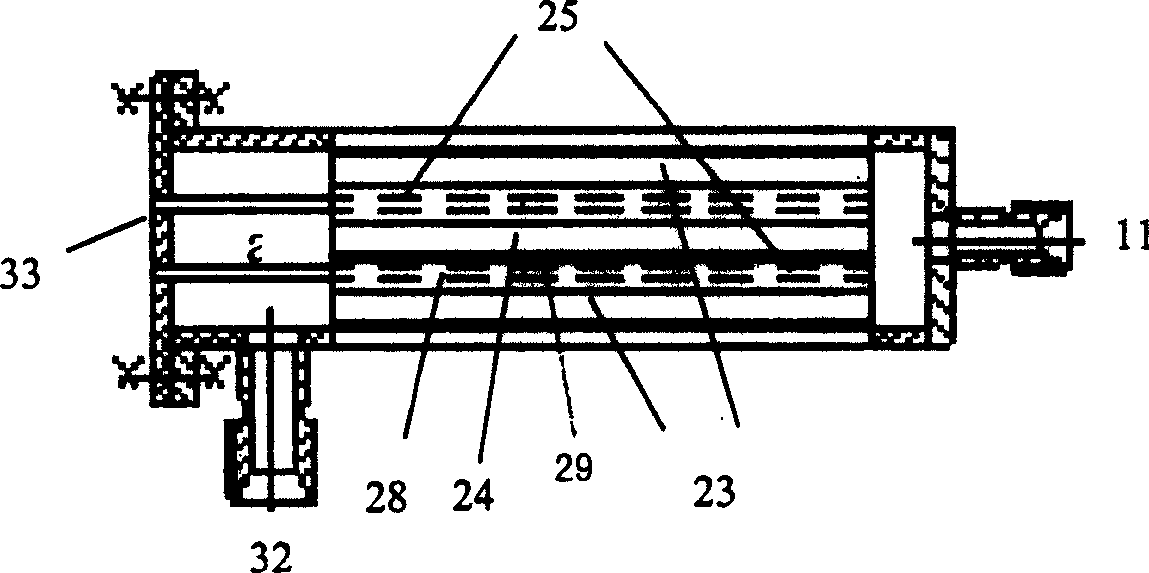

[0049] Such as figure 1 , figure 2 and image 3 The shown microchannel plate-fin steam reforming hydrogen production reactor has a design power of 0.5KW. Micro-channel plate-fin steam reforming hydrogen production reactor, the main part is a micro-channel plate-fin structure, plus several welded heads, a total of five chambers, there are two combustion chambers 25, a reforming chamber 24 and two gasification chambers 23, and there are 0.4mm thick heat conducting plates 30 between the chambers. A reforming chamber 24 is sandwiched between two combustion chambers 25, and a gasification chamber 23 is located on the other side of the two combustion chambers. The hydrogen-rich gas and air undergo a catalytic combustion reaction in the combustion chamber 25, releasing a large amount of heat. Part of the heat is mostly transferred to the reforming chamber 24 and the two vaporization chambers 23 through the 0.4 mm heat conducting plate 30 . The raw material liquid first enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com