A Partitioned Filling Method for Controlling Large Area Caving Disasters of Hard Roofs

A hard roof, large area technology, applied in the fields of filling, earthwork drilling, safety devices, etc., can solve the problems of high roof control cost, complicated construction process, difficult to effectively control hard roof, etc. The method is simple and reduces the effect of surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

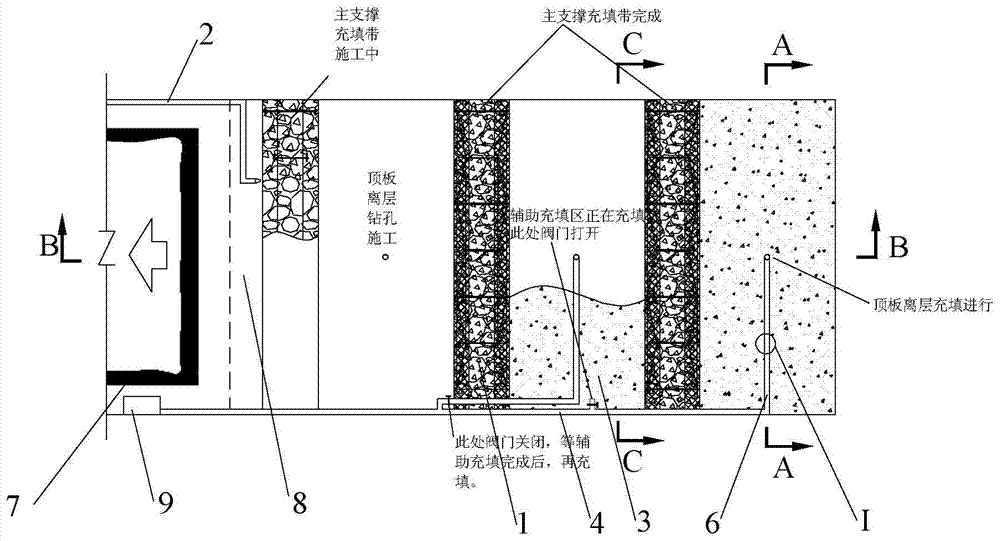

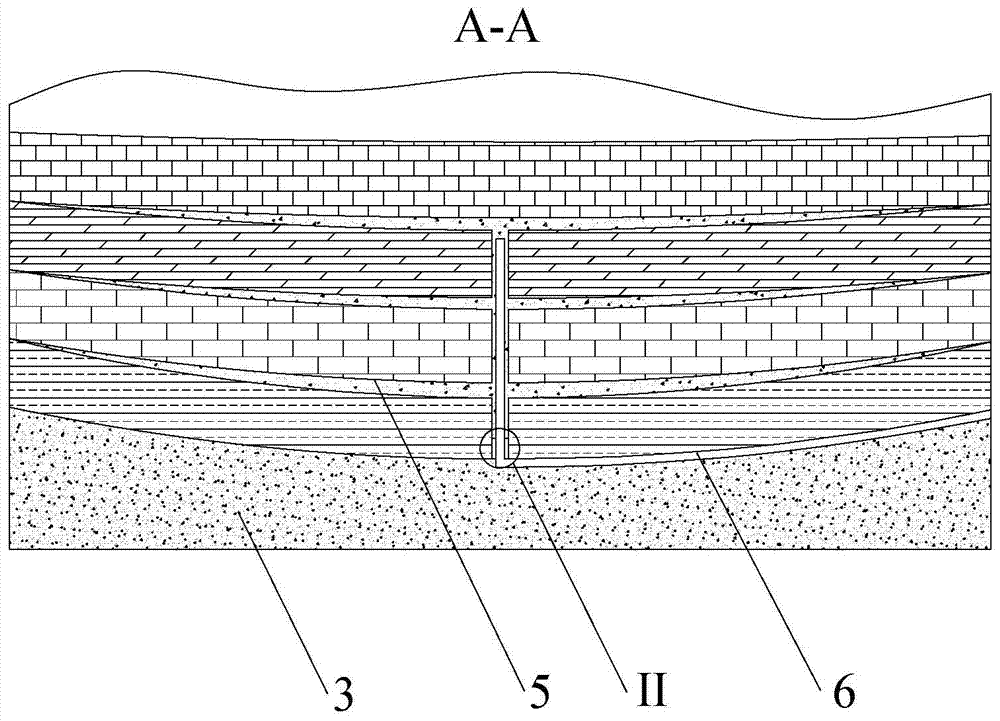

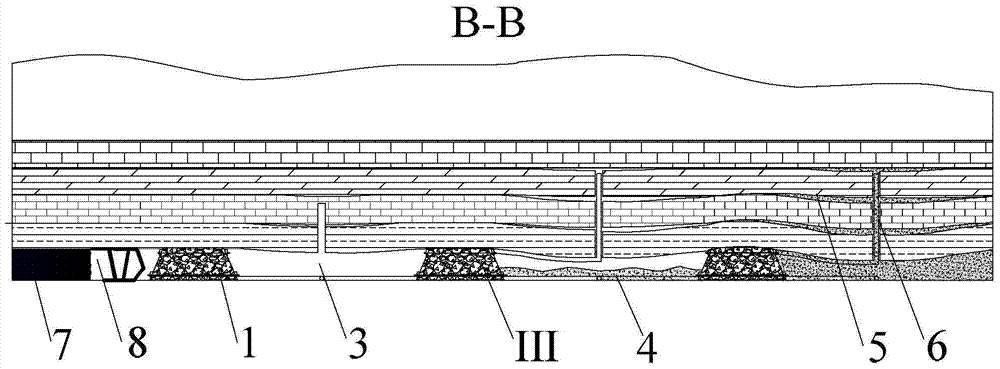

[0014] Such as figure 1 A partitioned filling method for controlling large-area collapse disasters of a hard roof is shown, including: the main support filling zone 1 in the goaf; the concrete grouting pipeline 2; the grouting area 3 for high-water materials in the goaf; Grouting pipeline 4 in the area; steel frame 4a; grouting hole 4b; roof separation zone 5; roof separation zone grouting pipeline 6; annular rubber sealing plug 6a; solid coal 7; working face 8; filling pump station 9; Reinforcing rigging; steel strands 10a; pallets 10b; reinforced ladder beams 10c; metal mesh 11.

[0015] A partition filling method for controlling large-area collapse disasters of a hard roof according to the present application. The supporting method is as follows: when the working face 8 advances a certain distance from the cut hole, lay corresponding At the same time, 1 to 3 deep holes are uniformly drilled into the roof at the rear of the entire working face, and the drilling depth reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com