Dielectric waveguide filter

A waveguide filter, dielectric technology, applied in waveguide devices, waveguides, circuits, etc., can solve problems such as low yield and high variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

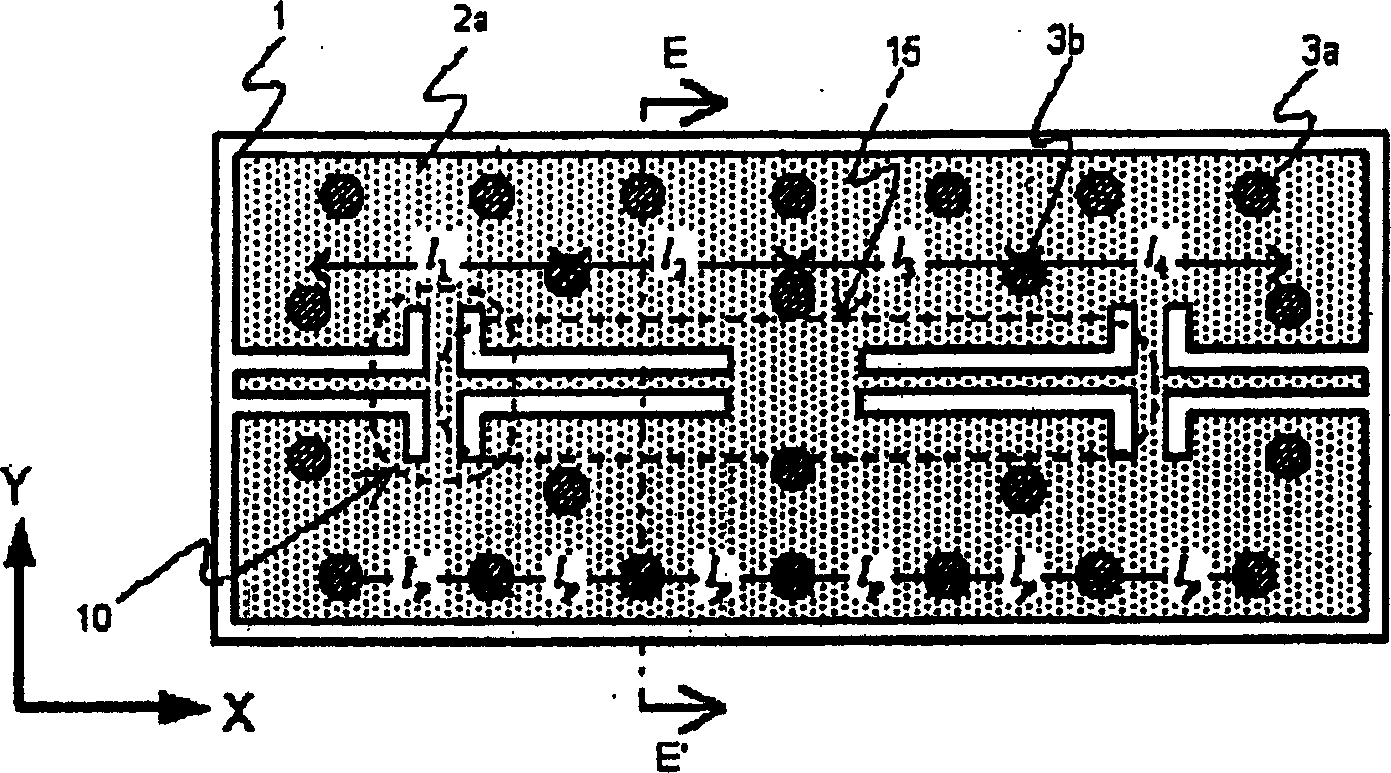

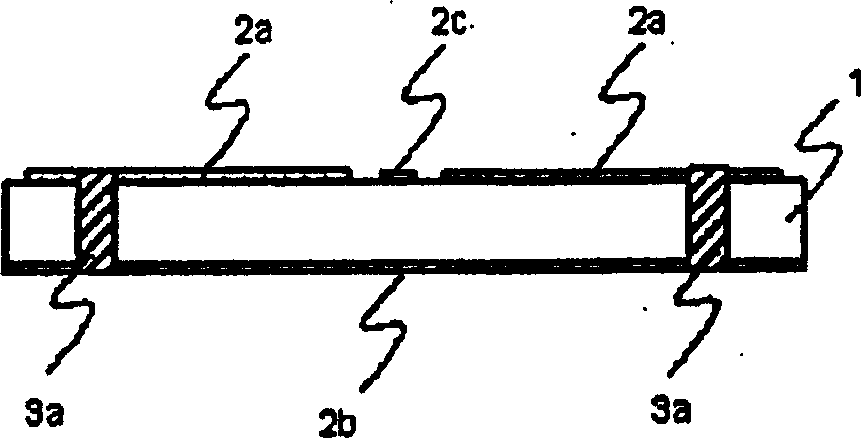

[0024] Referring now to FIG. 2, a first embodiment of the present invention will be described in detail. Figure 2A shows a plan view of the filter substrate, and Figure 2B shows along the Figure 2A The cross-sectional view of alternating long and short dashed lines A-A' in .

[0025] Upper and lower conductive layers 2 a and 2 b are formed on the upper and lower surfaces of the dielectric substrate 1 . The upper and lower conductive layers 2a and 2b are connected to each other through via holes 3a and 3b, thereby forming first-level, second-level, and third-level dielectric resonators 5a, 5b and 5c and input / output waveguide structures 4a and 4b, Wherein the through holes 3a and 3b are formed at an interval equal to or less than 1 / 2 of the wavelength in the dielectric substrate at the resonance frequency. The filter is configured so that the first-stage resonator 5a and the second-stage resonator 5b are coupled by an electromagnetic field by means of a dielectric window ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com