Method for treating carbonized sewage through cultivating and domesticating nitrobacterium and denitrified bacterium

A technology for denitrifying bacteria and coking sewage, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as inability to achieve denitrification, reduce domestication links, reduce Effects of running cost and shortening culture time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

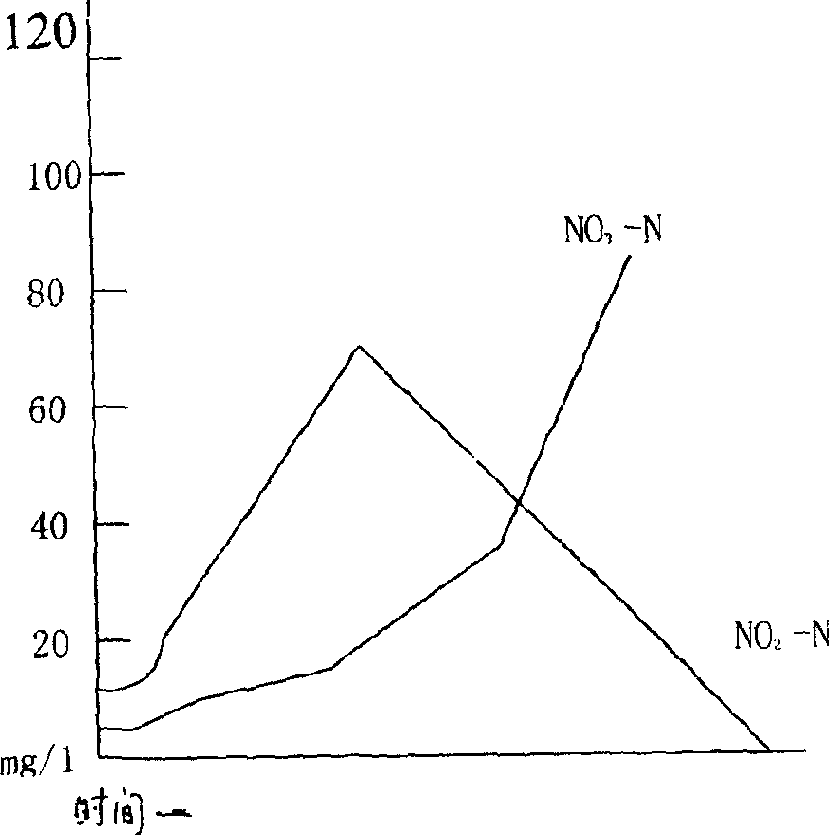

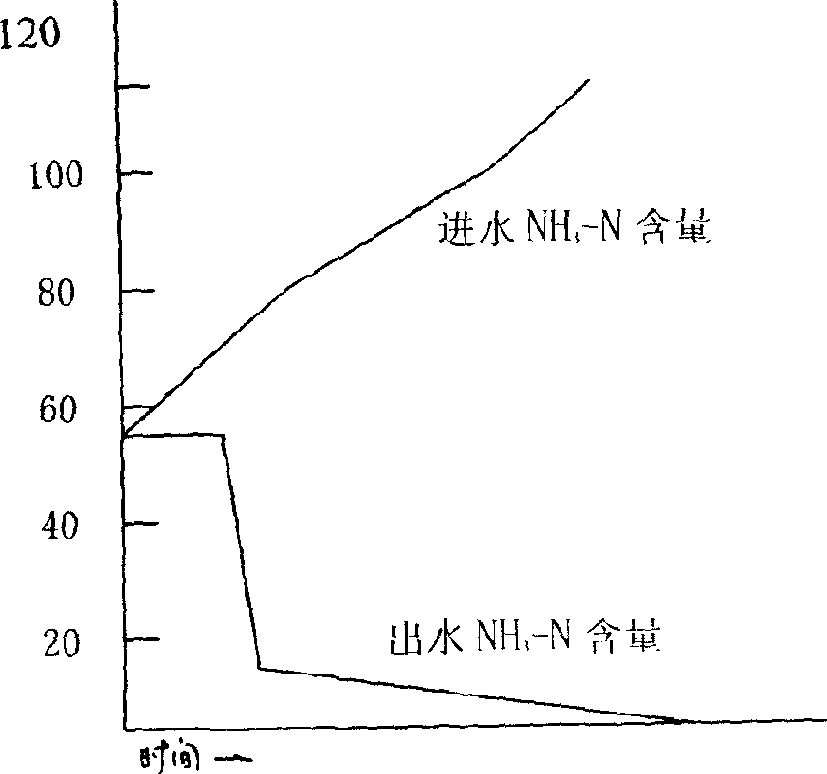

Image

Examples

Embodiment 1

[0033] 1. Collect the sewage generated in the production process of each workshop into the degreasing pool to remove heavy oil and some light oil;

[0034] 2. The effluent from the degreasing tank flows into the flotation tank to degrease again, creating a good water quality condition for the subsequent process; when the water quality is poor or the water volume is large, the effluent from the degreasing tank enters the regulating tank, and waits for the subsequent process When the load is reduced, it will be pumped back to the degreasing pool;

[0035] 3. The effluent from the flotation tank flows into the homogenization tank, and phosphorus salt is added as needed to mix it with the wastewater, and the phosphorus (P) content is controlled to 4-5mg / L, and then sent to the anaerobic tank;

[0036] 4. The anaerobic tank is equipped with a combined filler and a mixer. After the wastewater is fully stirred, it undergoes an acidification reaction with the biofilm (anaerobic bacter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com