Continuous flow operation method for prompting continuous flow sewage treatment system to achieve short range nitration quickly

A sewage treatment system, short-range nitrification technology, applied in water/sludge/sewage treatment, chemical instruments and methods, aerobic and anaerobic process treatment, etc., can solve problems such as unstable effect, long cycle of starting short-range nitrification, etc. Achieve the effects of stable short-range effect, short start-up period, and high ammonia nitrogen nitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing and example:

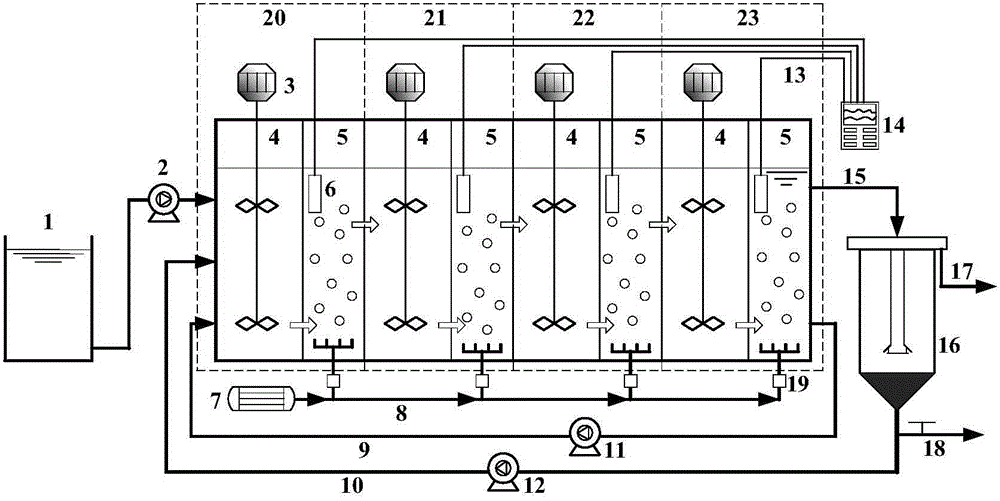

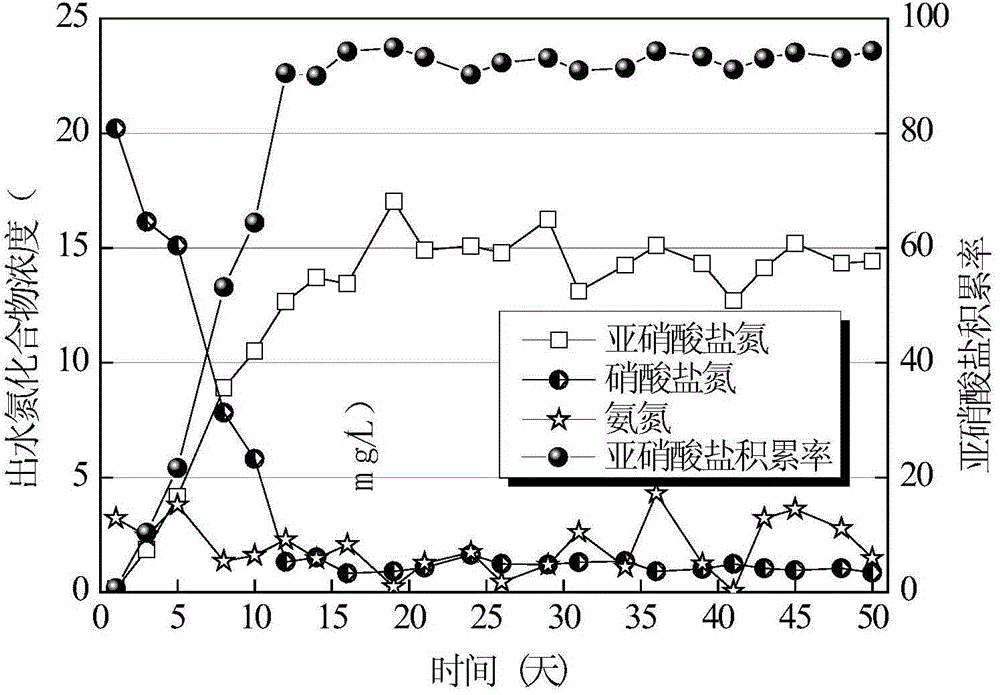

[0020] (1) Set the operation mode of continuous flow; figure 1 Shown is a schematic diagram of the continuous flow system modified according to the present invention, the continuous flow is transformed into four continuous sections (20-23), each section consists of anoxic zone (4) and aerobic zone ( 5) Composition, the effluent from the aerobic zone in the previous section flows into the anoxic zone in the next section, and the effluent from the aerobic zone in the last section enters the secondary sedimentation tank (16) through the biochemical tank outlet pipe (15) to achieve mud-water separation; the last aerobic zone A nitrifying liquid return pipe (9) and a nitrifying liquid return pump (11) are provided to connect the anoxic zone of the first section; the outlet water of the secondary settling tank is discharged through the outlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com