A method for starting and controlling multistage partial nitrosation

A control method and nitrosation technology, applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc. operation and other problems, to achieve the effects of low energy consumption for aeration and fluidization, high oxygen utilization rate, and adjustable volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0059] In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with specific embodiments.

[0060] Under the condition of continuous flow, the present invention adopts the suspended filler as the microorganism attachment carrier, which is different from the activated sludge method, and the microorganism is in a fixed state, which is more conducive to the retention of AOB (ammonia oxidizing bacteria); meanwhile, it is compatible with the fixed bed biofilm reactor The difference is that the carrier is fluidized, and the renewal of the biofilm is realized during the fluidized process. Through the control of the air-water ratio, the accumulation of NOB (nitrite oxidizing bacteria) in the mud age is prevented; at the same time, the intermittent aeration method is used to enrich the AOB. Set and NOB exclusion to create more favorable conditions. Low te...

Embodiment 1

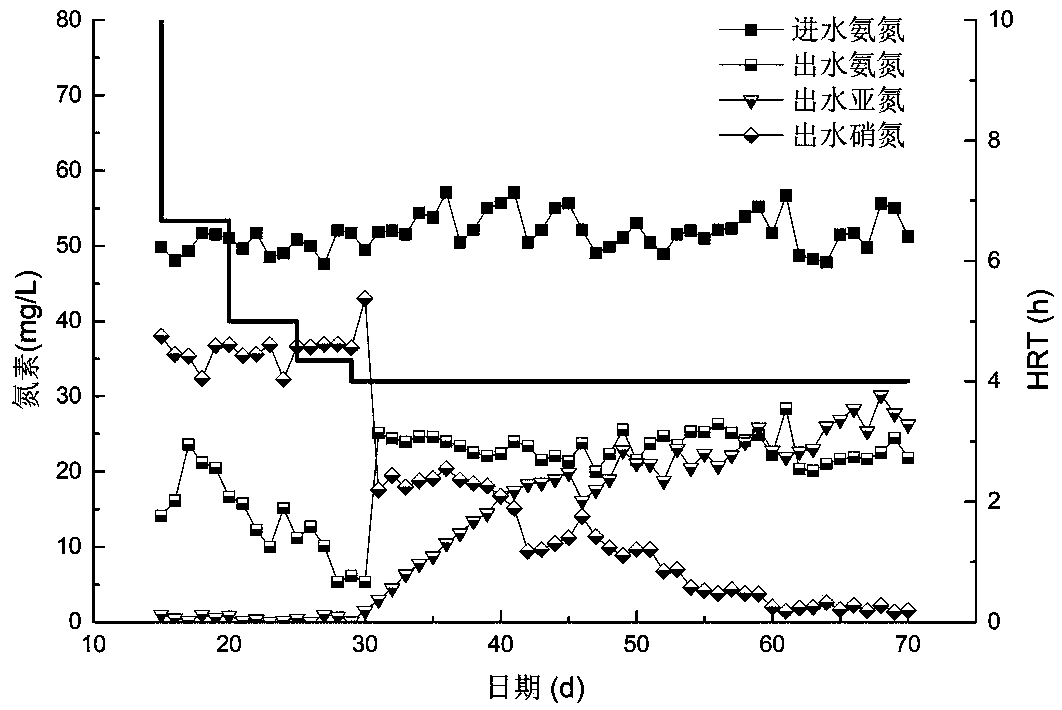

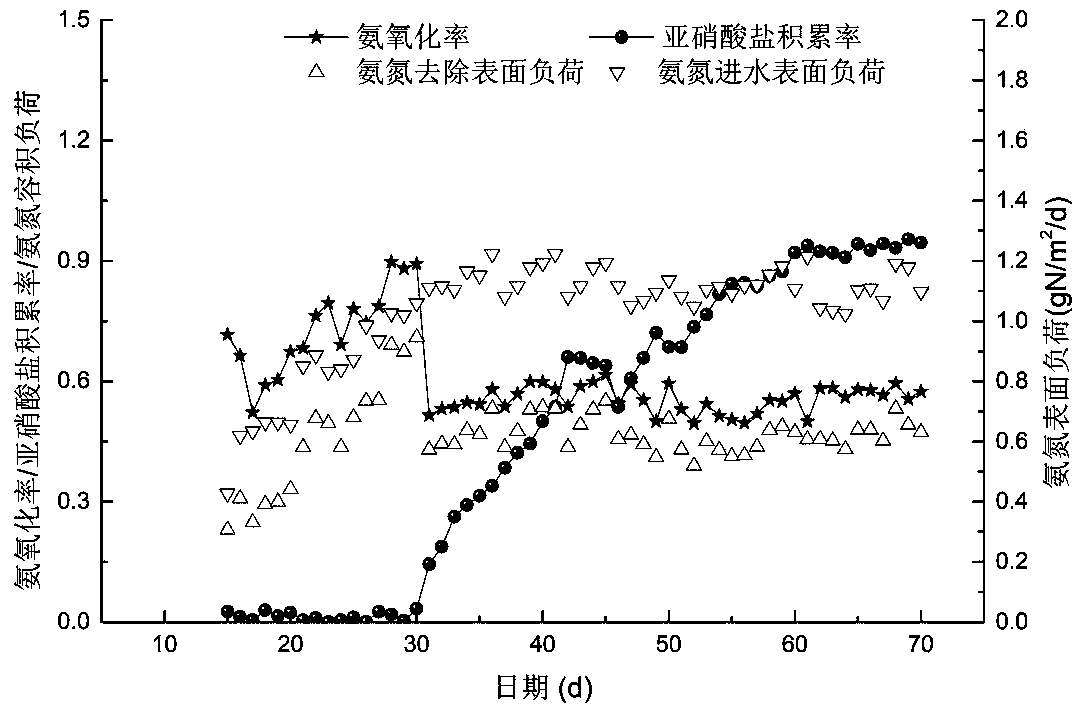

[0062] The reactor pool capacity is 10m 3 , using a specific surface area of 700m 2 / m 3 Suspended carrier, the specific gravity of the suspended carrier before film formation is 0.965, and the porosity is >95%; the reactor is divided into 8 stages, and the reactors at each stage have the same pool capacity and the same filling rate, and no sludge return is set. The concentration of suspended sludge is always <0.5g / L; the influent is decarbonized domestic sewage, the influent BOD is 10±3mg / L, TN is 55±6mg / L, ammonia nitrogen is 50±5mg / L, BOD : TN<0.2, influent SS<20mg / L, water temperature is 14±2℃;

[0063] 1) Start nitrification, fill suspension carrier 4m 3 , the filling rate is 40%, the DO is controlled at 4-5mg / L, and the activated sludge of the sewage plant is inoculated with 4g / L. Sludge, start continuous water inflow and aeration, initial HRT=10h, DO control at 4-5mg / L, by 15d, ammonia oxidation rate is 72%, ammonia nitrogen removal surface load is 0.306gN / (m 2 d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com