Figuring yarn guiding device of war knitting machine

A yarn guide device and warp knitting machine technology, which is applied in the field of warp knitting machines, can solve the problems of yarn guide needle offset, electrode composition, complex circuit structure, and high cost, and achieve good safety, reduce mechanical transmission, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] best practice

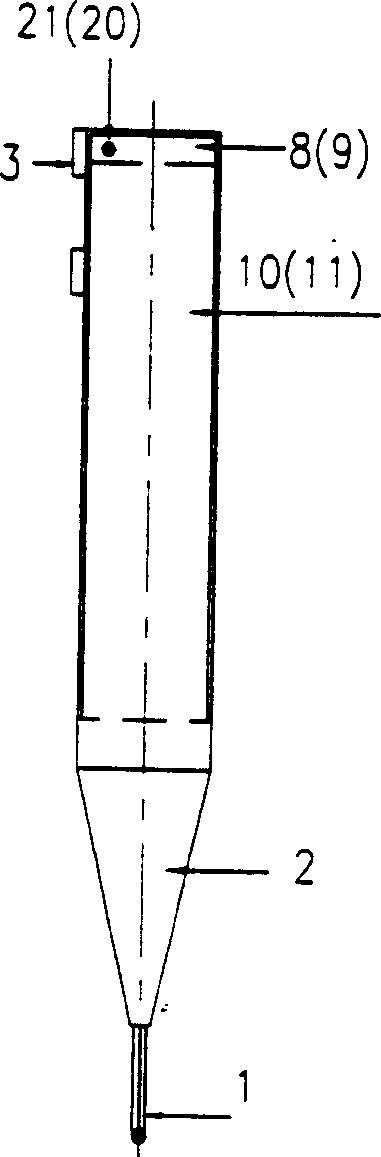

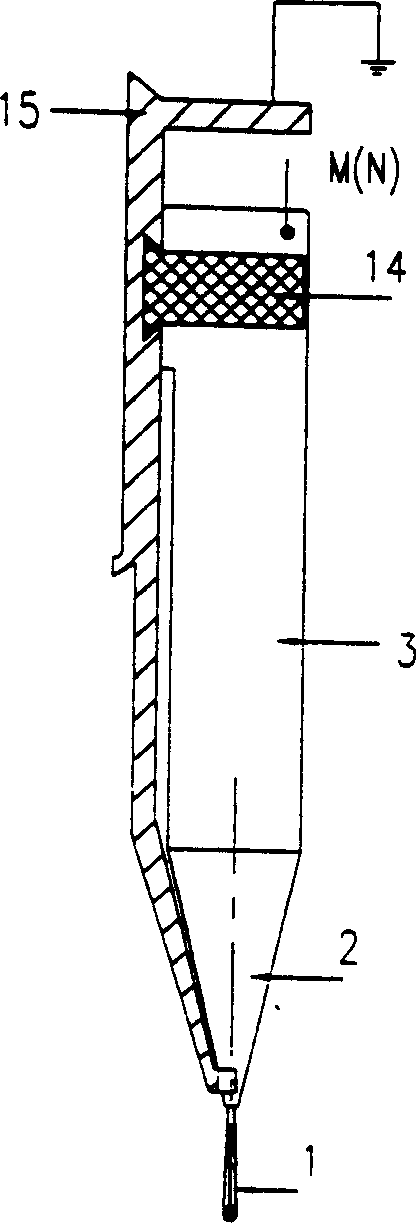

[0015] The guide needle 1 utilizes a connector 2 made of insulating material such as plastic, and is connected with the intermediate body 3 by injection molding, and the upper part of the intermediate body 3 is fixed on the bar 15 by a fixing device 14 made of insulating material.

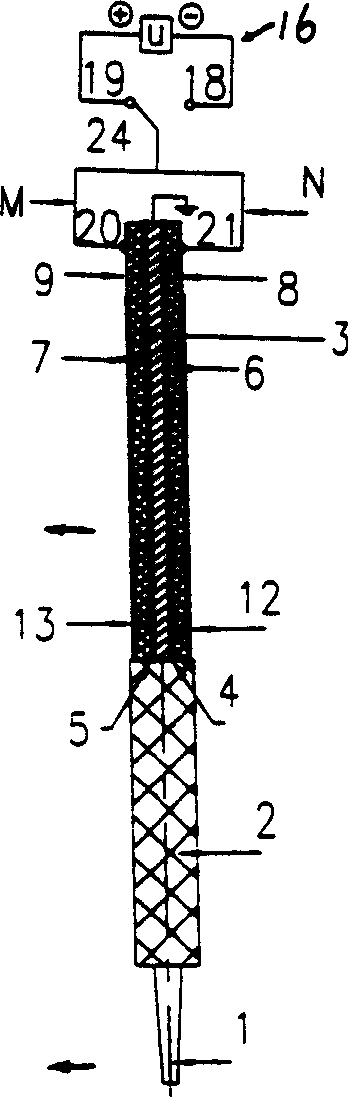

[0016] The intermediate body 3 is made of a conductive and elastic material such as a silicon steel sheet, and its two sides are coated with a conductive material such as a conductive glue, so that an internal electrode 4 and 5 are formed on both sides of the intermediate body 3, because the internal electrode 4 , 5 and the intermediate body 3 are all conductors, so the two internal electrodes 4 and 5 are electrically connected in phase.

[0017] The internal electrodes 4 and 5 are respectively covered by continuous piezoelectric layers 6 and 7, and continuous conductive coatings are respectively coated on the piezoelectric layers 6 and 7 to form external electrodes 8 and 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com