Depth detecting method with plastic drainage plate

A plastic drainage board and sounding technology, applied in the direction of measuring devices, instruments, soil protection, etc., can solve problems such as troublesome use, inability to ensure clear handwriting, and affecting the detection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A depth-measuring method for a plastic drainage board according to the present invention, comprising the following steps:

[0045] A) Two copper wires that can form a path at the bottom end are arranged side by side in parallel inside the plastic drainage board.

[0046]B) Test the plastic drainage board with copper wire in the room to determine the material coefficient a 1 ;a 1 Determined by:

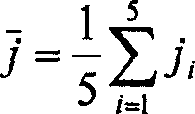

[0047] a 1 =l / R formula: R is the average value of tested metal wire through repeated tests, and l' is the average length of multiple groups of metal wire tests.

[0048] C) Through the set depth test on site, the construction technical index a of the construction unit can be obtained 2 , b 2 .

[0049] D) During construction, first connect the copper wires at the bottom of the plastic drainage board together to form a loop; then drive the plastic drainage board to the depth to be measured.

[0050] E) Connect the copper wire at the top of the plastic drainage board to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com