Electric core structure of lithium battery and producing method thereof

A manufacturing method and technology for lithium batteries, which are applied in secondary batteries, final product manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems of time-consuming and labor-intensive pole piece processing, affecting the overall thickness, and being unsightly, so as to improve production efficiency and improve productivity. Product quality, reduction of low voltage plateau, reduction of the effect of welding toe repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

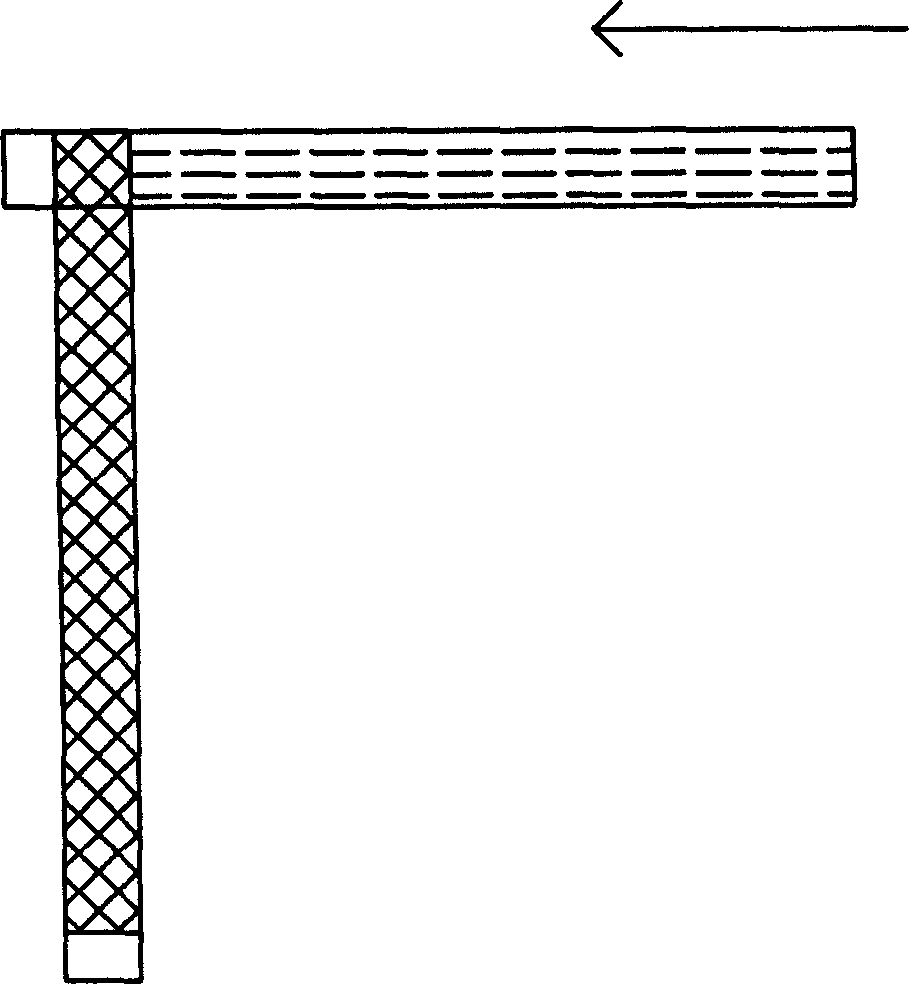

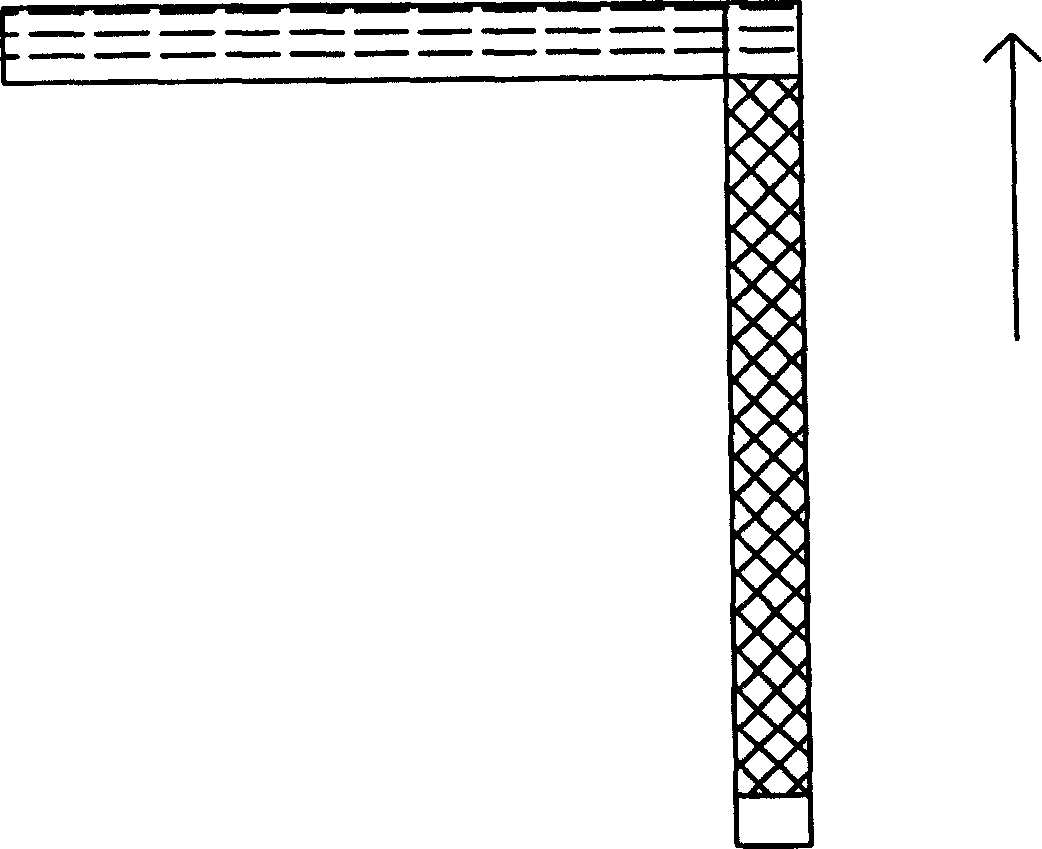

[0011] The cell structure and its manufacturing method disclosed in the present invention is an efficient and fast method for liquid flexible packaging or polymer lithium-ion cells, which is compatible with industrial production, and strives to combine the traditional laminated sheet structure after punching with the The combination of winding core structure simplifies the production process in actual production, speeds up the flow operation, and improves the packaging and sealing quality of formed batteries.

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

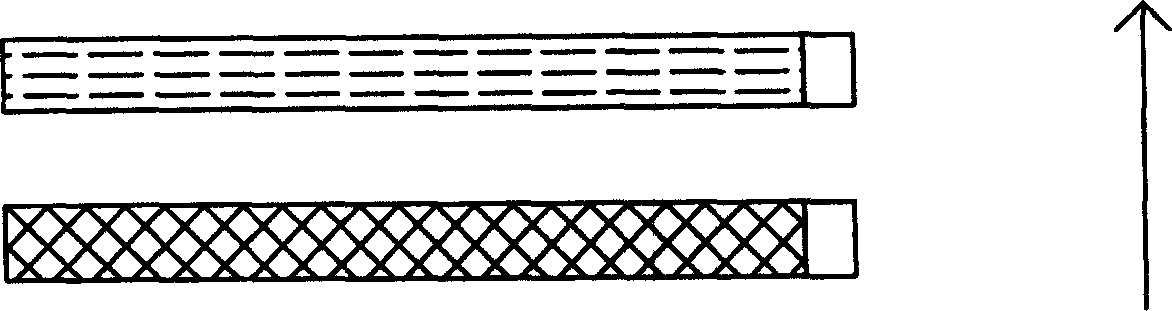

[0013] The invention eliminates the necessary punching process of the traditional stacked pole piece type lithium battery, and adopts the strip pole piece of the core type lithium battery type, so the positive pole piece 1, the negative pole piece 2 and the positive pole piece sandwiched between the positive pole piece and the negative pole piece a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com