Prepn process of porous metal materrial

A metal porous and metal powder technology, which is applied in the field of preparing metal porous materials, can solve the problems of high porosity, low strength and toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

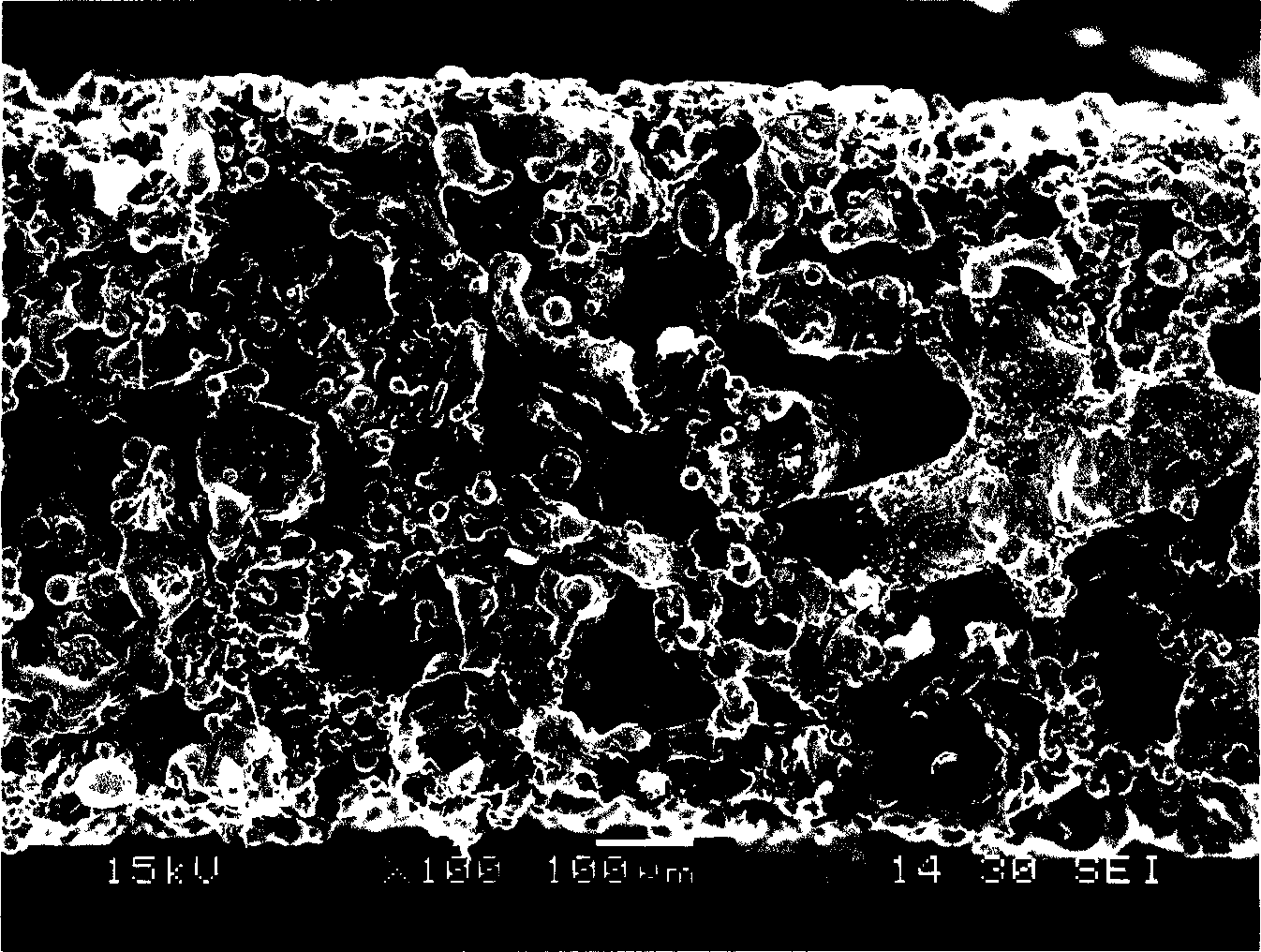

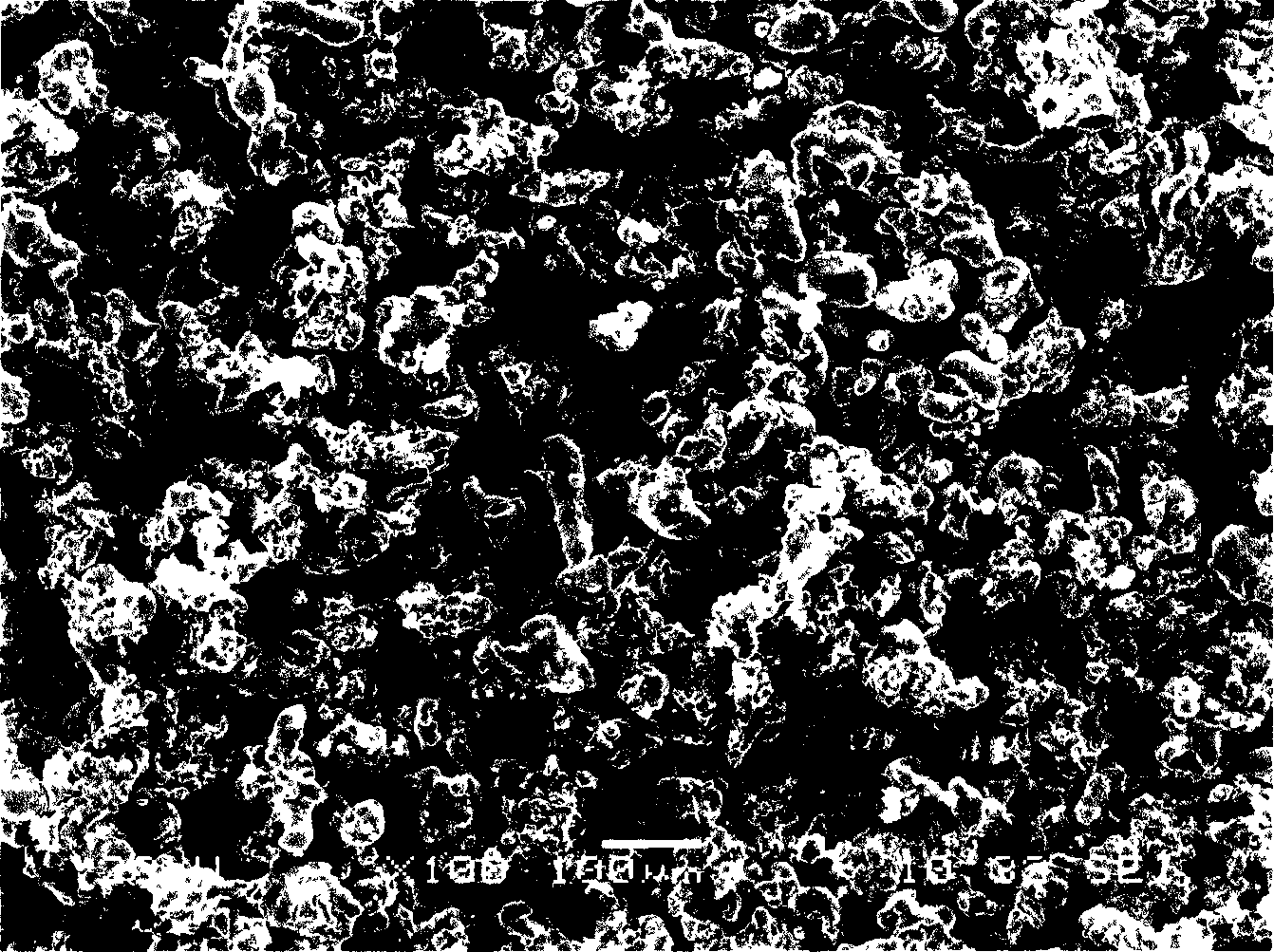

[0017] Atomize 1Kg of stainless steel powder with SUS304L water with a sieving particle size of 10-175 μm and an average particle size of 50.37 μm, use hydroxymethyl cellulose as a binder, make a 2% aqueous solution, and add 500ml / Kg of metal powder for bonding Add 500ml of aqueous solution and mix well. The wire mesh is a commercially available 60-mesh 304 stainless steel wire mesh with a wire diameter of 0.18mm. The wire mesh is cut into a rectangle of 250mm×500mm, and the sheet weighs 78g. The wire mesh is cleaned with a metal cleaning agent to remove surface dirt, and then 20% 1HNO is used 3 +3HCl aqueous solution, soak for 20min., then rinse with water. First, tension the single-layer wire mesh with a bracket, and then use a rigid scraper to drive the slurry to slide at 45° along the tensioned wire mesh plane, so that the slurry can be evenly filled into the mesh grid and spread evenly on the surface of the wire mesh. Tiling, coating thickness 0.92mm. The coated blank ...

Embodiment 2

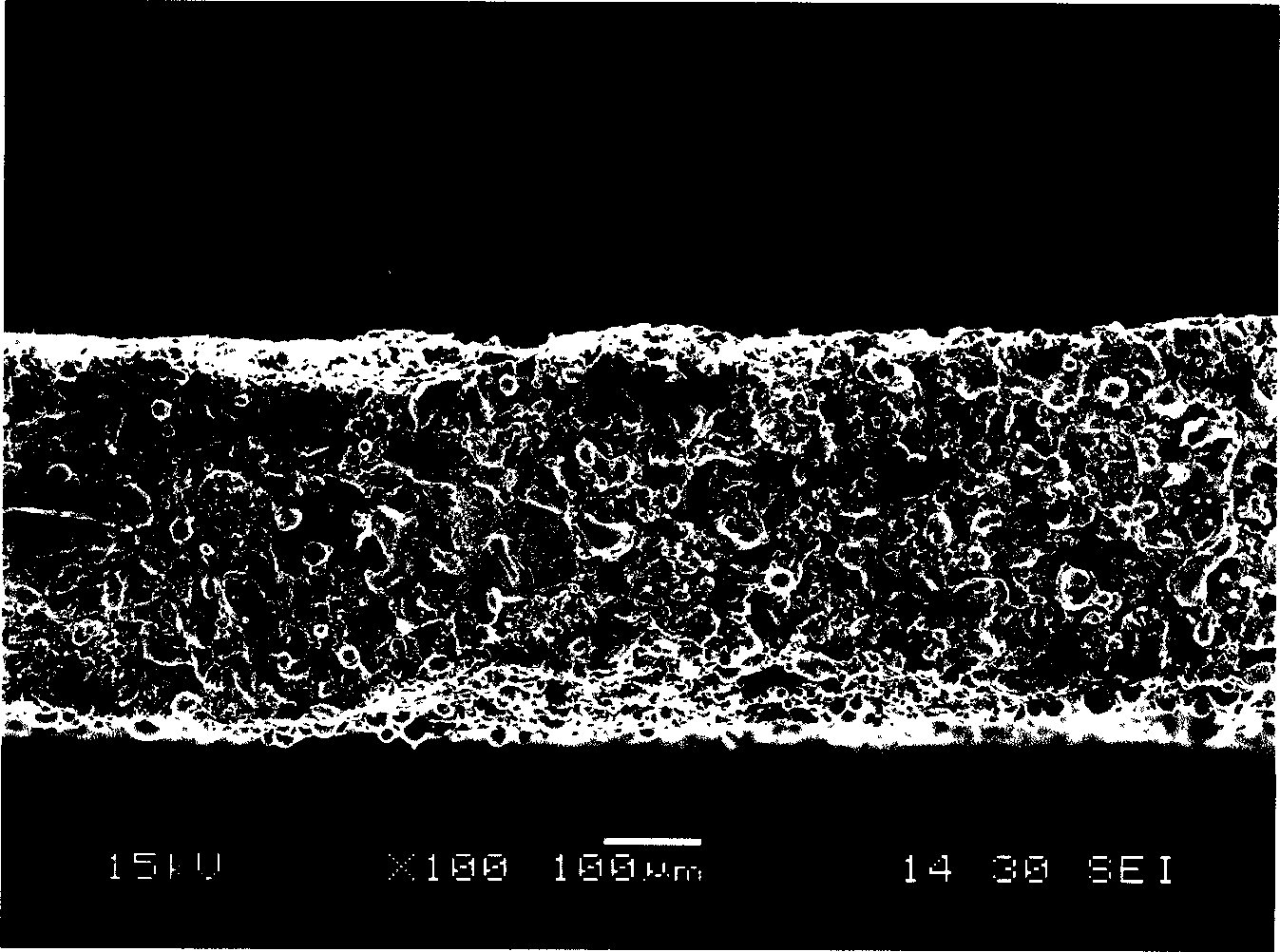

[0019] SUS304L water-atomized stainless steel powder with a sieving particle size of 4-90 μm and an average particle size of 36.72 μm is used, and the other is the same as in Example 1. The coating thickness is 0.65 mm, and the thickness before and after rolling is 0.62 mm and 0.52 mm respectively. Finally, this product is obtained. The single-sheet area of the invention is 250mm×500mm, and the stainless steel porous body weighs 135g.

Embodiment 3

[0021] SUS304L water-atomized stainless steel powder with a sieving particle size of 2 to 70 μm and an average particle size of 25.87 μm is used, and the others are the same as in Example 1. The coating thickness is 0.55 mm, and the thicknesses before and after rolling are 0.50 mm and 0.42 mm respectively. Finally, this product is obtained. The single-sheet area of the invention is 250mm×500mm, and the stainless steel porous body weighs 124g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com