Testing method for on-line monitoring internal insulation incipient fault of electric equipment

A technology for power equipment and internal insulation, applied in the direction of testing dielectric strength, etc., can solve problems such as inability to effectively prevent sudden failure of power equipment and affect power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: A test method for on-line monitoring of hidden dangers of insulation inside a transformer.

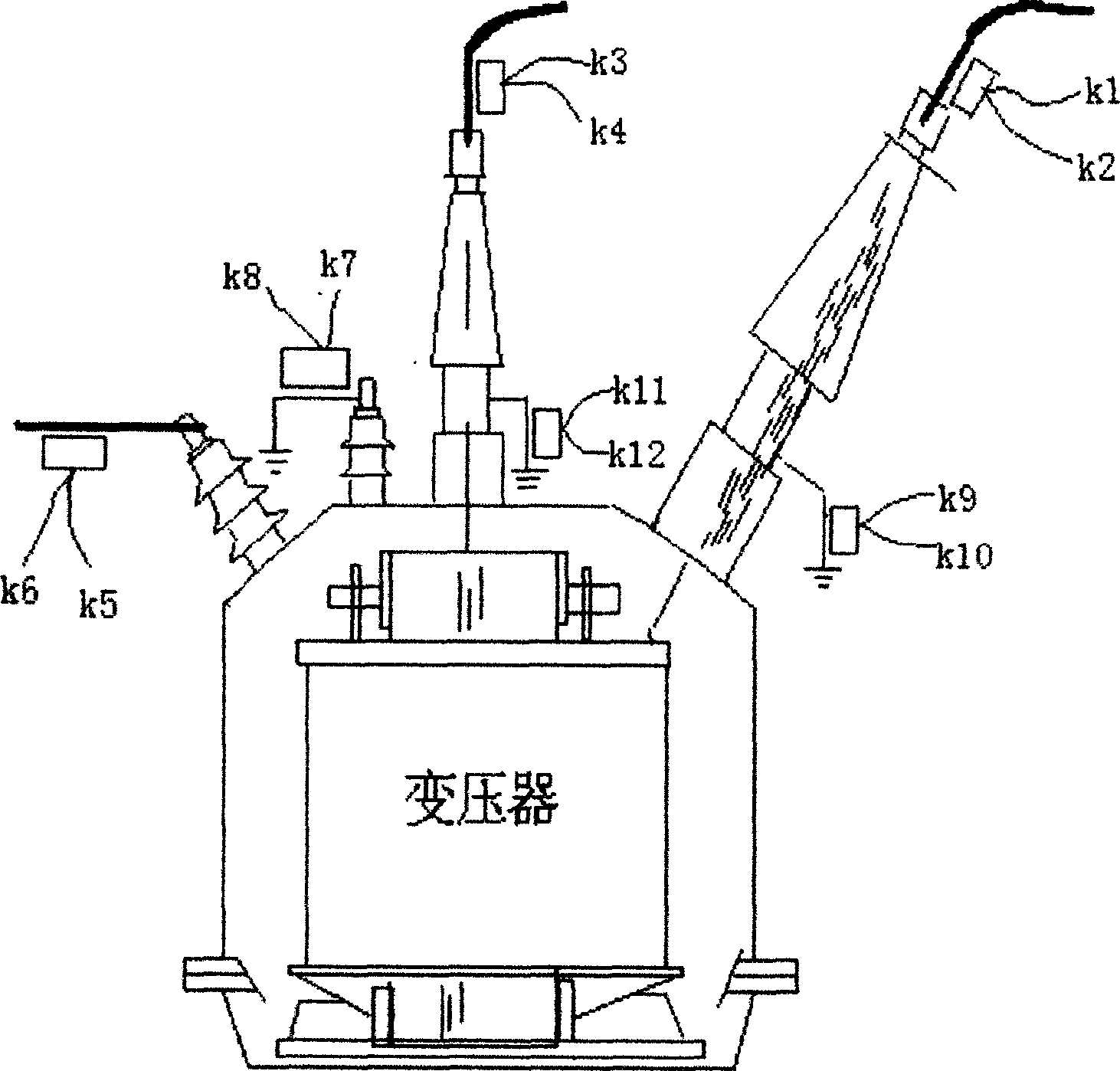

[0013] like figure 1 Shown:

[0014] 1. From the strong magnetostrictive amorphous alloy sensors K1 and K2 installed on the high-voltage bushing of the transformer in a non-core-through installation method, the strong magnetostrictive amorphous alloy sensors K3 and K4 on the neutral point bushing, and the low-voltage The strong magnetostrictive amorphous alloy sensors K5 and K6 on the bushing, and the strong magnetostrictive amorphous alloy sensors K7 and K8 on the core grounding bushing collect the impact high frequency and large current signal as the excitation signal and response signal of the transformer transfer function , calculate the transfer function curve of the wave process when the high frequency and large current impacts the transformer each time, according to the change of the transfer function curve, analyze the impact high frequency and large curre...

Embodiment 2

[0018] Embodiment 2: A test method for on-line monitoring of hidden dangers of insulation inside a transformer.

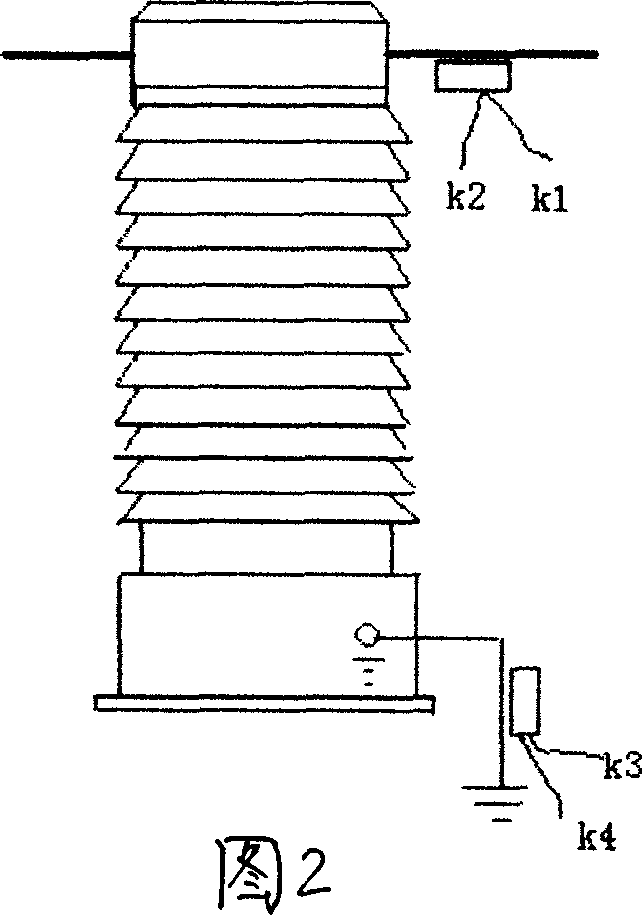

[0019] as shown in picture 2:

[0020] From the strong magnetostrictive amorphous alloy sensors K1 and K2 installed on the high-voltage bushing of the transformer in the non-core-through installation method, and the strong magnetostrictive amorphous alloy sensors K3 and K4 on the grounding bushing, the impact high-frequency large The current signal is used as the excitation signal and response signal of the transfer function of the transformer equipment, and the transfer function curve of the time wave process of each high-frequency and large current impact on the transformer is calculated. According to the change of the transfer function curve, the collected high-frequency and large current waveform is studied. Analysis, and in conjunction with other routine tests, real-time evaluation and fault diagnosis of transformer insulation performance.

[0021] The signal...

Embodiment 3

[0022] Embodiment 3: A test method for on-line monitoring of hidden dangers in the internal insulation of lightning arresters.

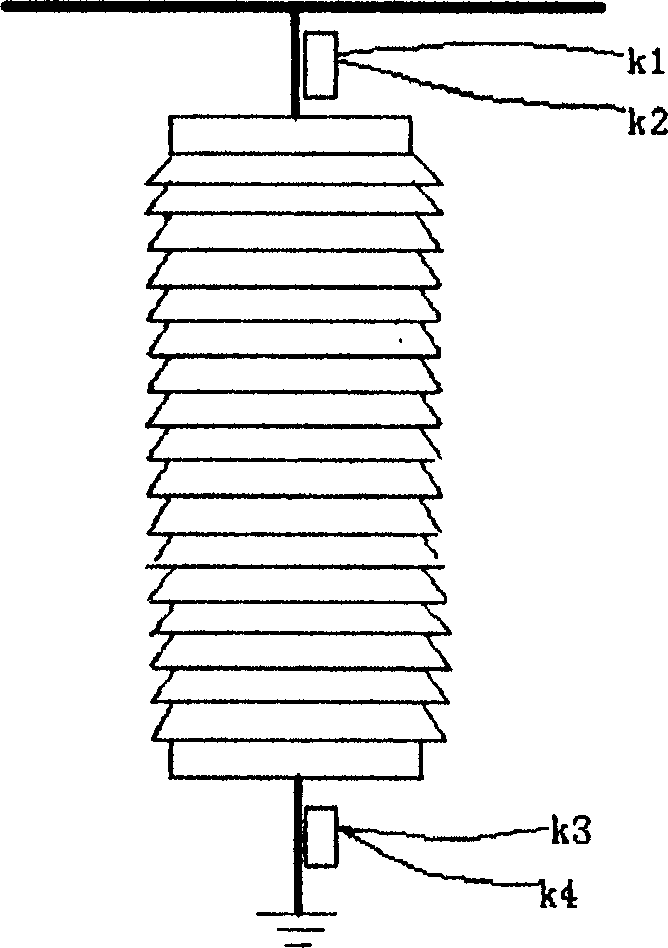

[0023] like image 3 Shown:

[0024] Collect high-frequency and high-current signals from the strong magnetostrictive amorphous alloy sensors K1 and K2 installed on the high-voltage bushing of the arrester in a non-core-through installation method, and the strong magnetostrictive amorphous alloy sensors K3 and K4 on the grounding bushing As the excitation signal and response signal of the transfer function of the arrester equipment, calculate the transfer function curve of the time wave process of each high-frequency and large-current impact arrester, and analyze the collected high-frequency and large-current waveform according to the change of the transfer function curve, and cooperate with Other routine tests, real-time evaluation and fault diagnosis of arrester insulation performance.

[0025] The signals collected by the above-mentioned strong ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com