Modified method for electrolytic manganese dioxide for lithium battery

A technology for electrolysis of manganese dioxide and lithium batteries, applied in battery electrodes, manganese oxide/hydroxide, circuits, etc., can solve problems such as the reduction of the actual molar ratio, and achieve the effect of improving electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

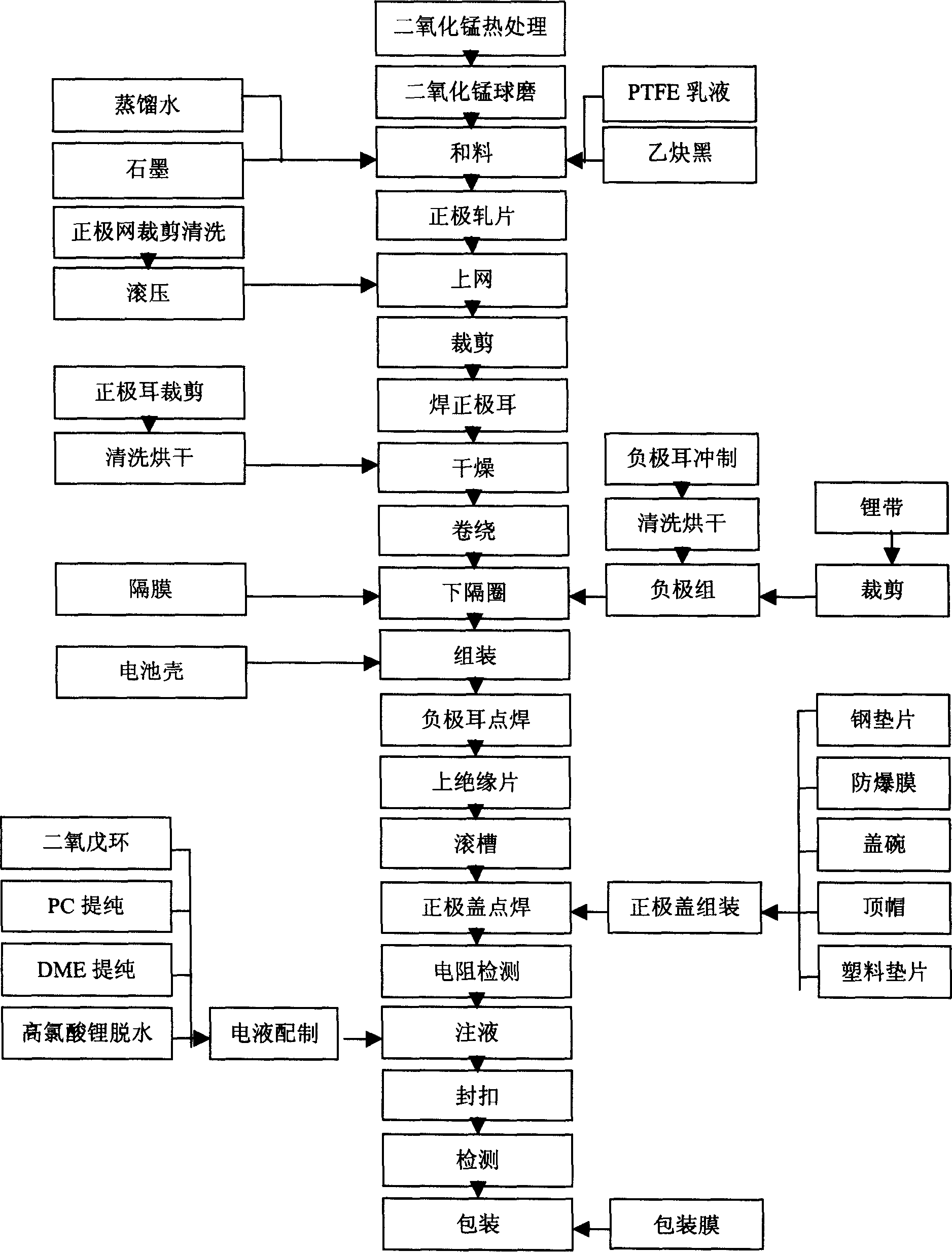

Image

Examples

Embodiment 1

[0028] Modification method of electrolytic manganese dioxide for lithium battery, γ-MnO after electrolysis 2 The powder is treated in a blast drying oven at 500°C at 375°C for 24 hours, and 95% oxygen is continuously supplied to the blast drying oven to make the oxygen convect in the high temperature space. Modified MnO 2 From the γ crystal form to the γ and β mixed crystal form (the β crystal form accounts for 40%-60%).

[0029] The above-mentioned modified electrolytic manganese dioxide was assembled according to the production process requirements of CR123A battery to assemble the CR123A experimental battery, and at the same time, the normal modified electrolytic manganese dioxide was used as a blank comparison. See the battery discharge results of the first, second and third experiments.

[0030] Experimental battery of oxygen-enriched modified electrolytic manganese dioxide of the present invention

[0031] Experimental battery of oxygen-enriched mo...

Embodiment 2

[0034] Modification method of electrolytic manganese dioxide for lithium battery, γ-MnO after electrolysis 2 The powder is treated in a blast drying oven at 500°C at 370°C for 24 hours, and 98% oxygen is continuously supplied to the blast drying oven to make the oxygen convect in the high temperature space.

Embodiment 3

[0036] Modification method of electrolytic manganese dioxide for lithium battery, γ-MnO after electrolysis 2 The powder is treated in a blast drying oven at 500°C at 380°C for 24 hours, and 100% oxygen is continuously supplied to the blast drying oven to make the oxygen convect in the high temperature space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com