Nucleoprotamine and sodium alginate microcapsule and its preparation method

A technology of protamine and sodium alginate is applied in the directions of microcapsule preparation, microcapsule, microsphere preparation, etc., and achieves the effects of mild preparation conditions, low price, easy application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

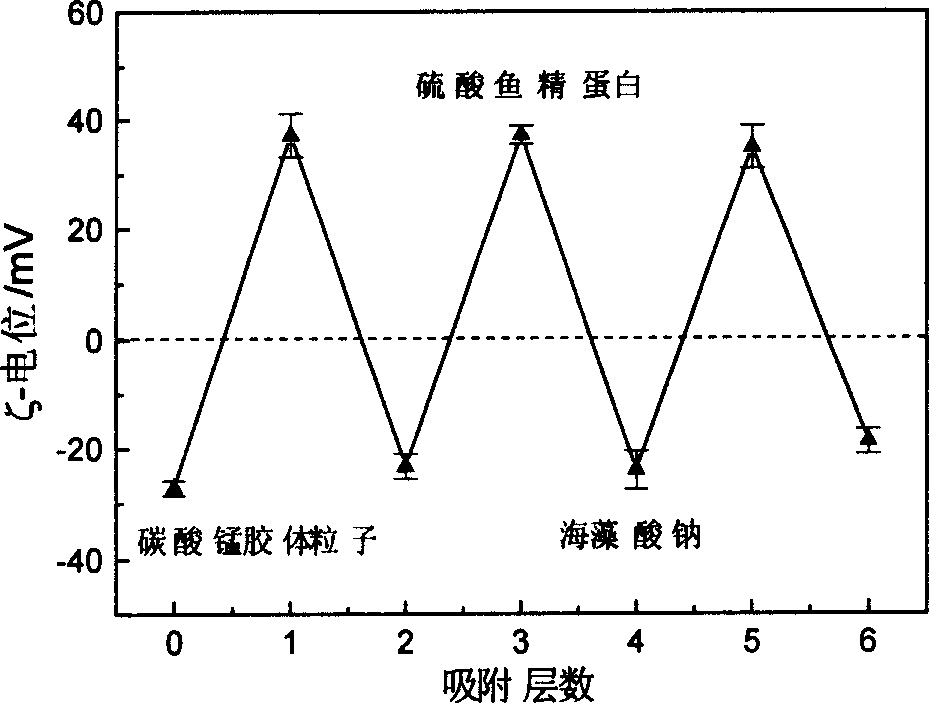

[0029] (1) First heat 1.36 g / L manganese sulfate solution and 1.8 g / L ammonium bicarbonate solution to 50°C respectively, then add sodium polystyrene sulfonate into the manganese sulfate solution, stir evenly, and finally stir under high speed , quickly add an equal volume of ammonium bicarbonate solution to the manganese sulfate solution, the concentration of sodium polystyrene sulfonate is 0.4 g / L, and react at a constant temperature of 50° C. for 1 hour to obtain manganese carbonate colloidal particles. The manganese carbonate colloidal particles are centrifuged and washed for later use. Gained colloidal particles are uniform in size and regular in appearance, and the particle size is about 1.5 microns (see figure 1 ).

[0030] (2) Add manganese carbonate colloidal particle dispersion to 2 g / L protamine sulfate (containing 29 g / L sodium chloride) aqueous solution, sonicate for one minute, then place it on an oscillator and vibrate for 20 minutes, until it is fully absorbed...

Embodiment 2

[0033] (1) Add sodium polystyrene sulfonate to 10 g / L of manganese sulfate solution, stir evenly, the concentration of sodium polystyrene sulfonate is 1 g / L, then under high-speed stirring, an equal volume of 8 g / L One liter of ammonium bicarbonate solution was quickly added to the manganese sulfate solution, and reacted at a constant temperature of 20° C. for 0.5 hour to obtain manganese carbonate colloidal particles. The manganese carbonate colloidal particles are centrifuged and washed for later use. The size of the obtained colloidal particles is about 10 microns.

[0034](2) Add manganese carbonate colloidal particle dispersion to 0.5 g / L protamine (containing potassium chloride 50 g / L) aqueous solution, sonicate for one minute, then place on an oscillator and vibrate for 10 minutes, until it is fully absorbed. Then through three times of "centrifugation / removal of supernatant / dispersion with high-purity water" to remove unadsorbed protamine. Then add 0.5 g / L sodium alg...

Embodiment 3

[0037] (1) Heat 0.1 g / L manganese sulfate solution and 0.1 g / L ammonium bicarbonate solution to 80°C respectively, under high-speed stirring, quickly add an equal volume of ammonium bicarbonate solution into the manganese sulfate solution, 80°C React at constant temperature for 2 hours to obtain manganese carbonate colloidal particles. The manganese carbonate colloidal particles are centrifuged and washed for later use. The size of the obtained colloidal particles is about 0.5 micron.

[0038] (2) Add manganese carbonate colloidal particle dispersion to 5 g / L protamine sulfate (containing 10 g / L sodium bromide) aqueous solution, sonicate for one minute, then place on an oscillator and vibrate for 60 minutes, until it is fully absorbed . Then through three times of "centrifugation / removal of supernatant / dispersion with high-purity water" to remove unadsorbed protamine. Then add 5 g / L sodium alginate (molecular weight of sodium alginate is 3.5 million, containing potassium ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com