Oxygen stewing separation method and equipment used therefor

A separation method, chlorine oxygen technology, applied in the direction of inorganic alkali pulping, etc., can solve the problems of large water, electricity, heat and other energy consumption, continuous production of cooking method, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

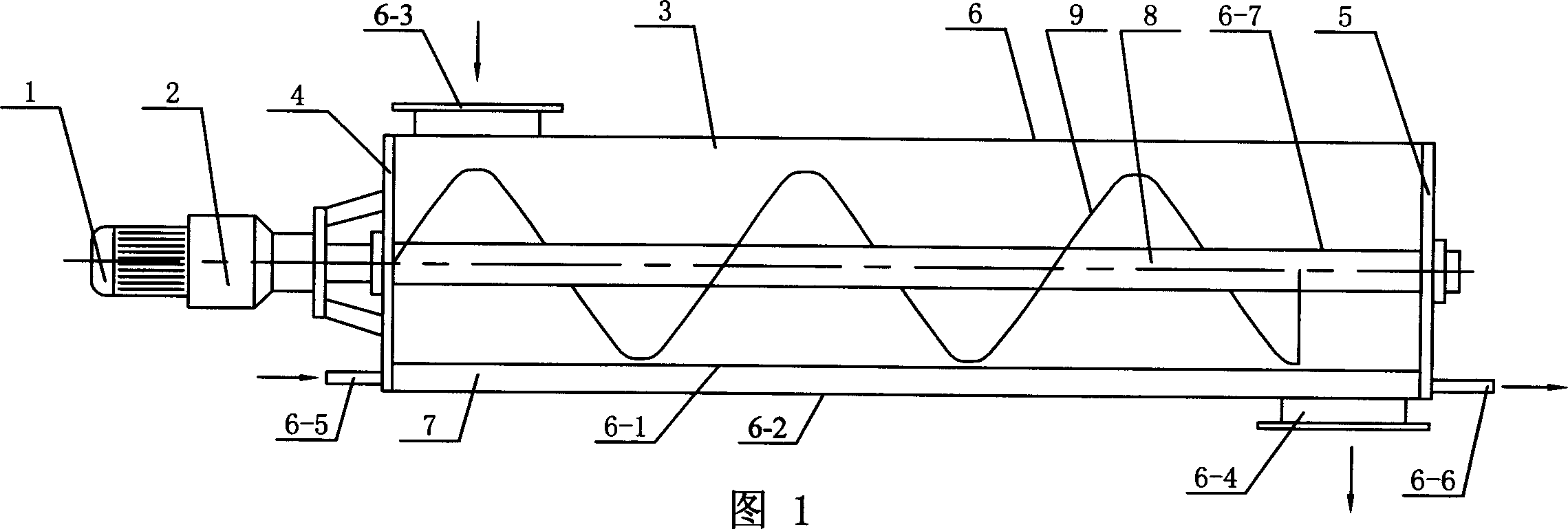

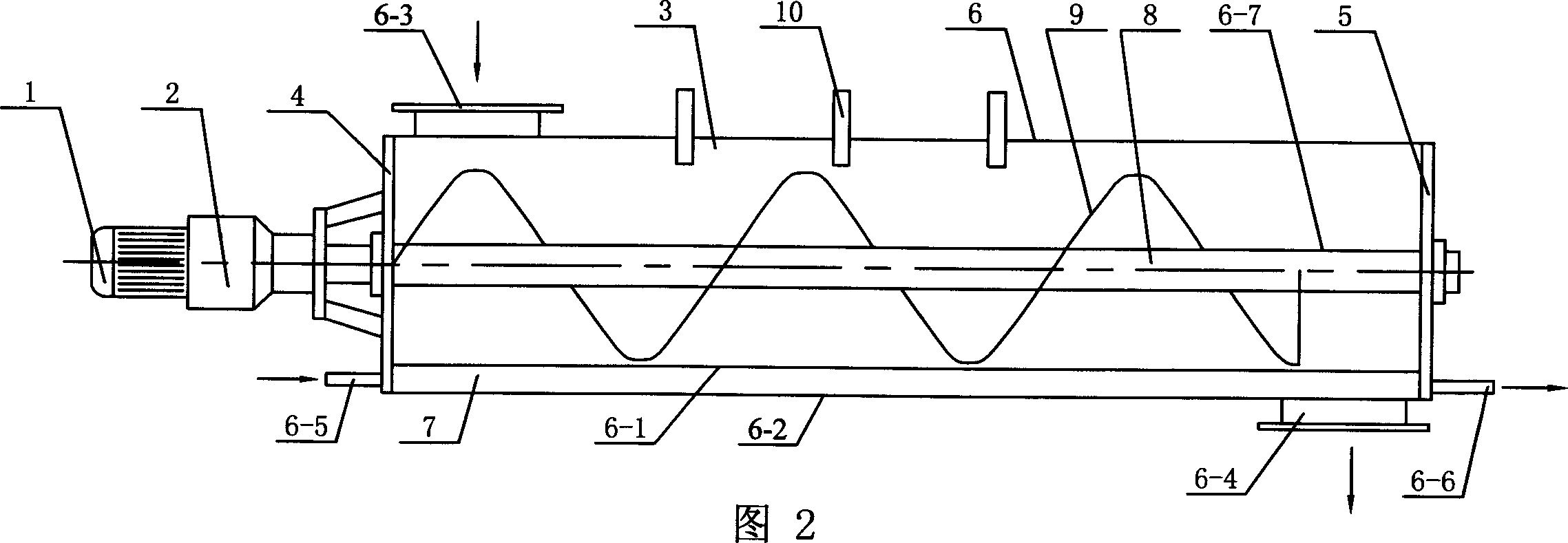

[0005] Specific embodiment 1: Referring to Fig. 1, this embodiment is realized in the following way: a, the straw silk of herbaceous plant is added in the oxygen stir-fried separation straw silk machine; b, preparation auxiliary agent, described auxiliary agent is made of the following components Mixed according to weight percentage: alkali 3-10%, alkaline hydrogen peroxide 70-85%, sodium silicate 3-10%, grafted starch 0.5-1.5%, magnesium sulfate 0.5-2%, chlorine oxygen 5- 15%; c. Add the prepared additives into the oxygen-stirred and separated straw silk machine, mix them evenly with the straw silk, and heat the heat-conducting oil to stir-fry the straw silk, so that the additives can quickly penetrate into the straw cavity wall, and the reaction temperature The temperature is 60-90°C, the reaction time is 100-120 minutes per ton of material, and the amount of additives added is 3-5% of the total weight of the material.

specific Embodiment approach 2

[0006] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the auxiliary agent is mixed according to the weight percentage of the following components: 4-8% of alkali, 72-82% of alkaline hydrogen peroxide, silicon Sodium phosphate 4-8%, grafted starch 0.8-1.2%, magnesium sulfate 0.8-1.8%, chlorine oxygen 8-12%. Other compositions and process parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0007] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the auxiliary agent is formed by mixing the following components according to weight percentage: 7% alkali, 75% alkaline hydrogen peroxide, and 6% sodium silicate , grafted starch 0.9%, magnesium sulfate 1.1%, chlorine oxygen 10%. Other compositions and process parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com