Process for preparing crystal seed used for rutile type titanium dioxide production

A technology of rutile-type titanium dioxide and calcined seed crystals, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of poor achromatic power, poor washing effect, and high impurity content, so as to improve the impurity removal effect and shorten the washing time. Time, the effect of improving the washing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

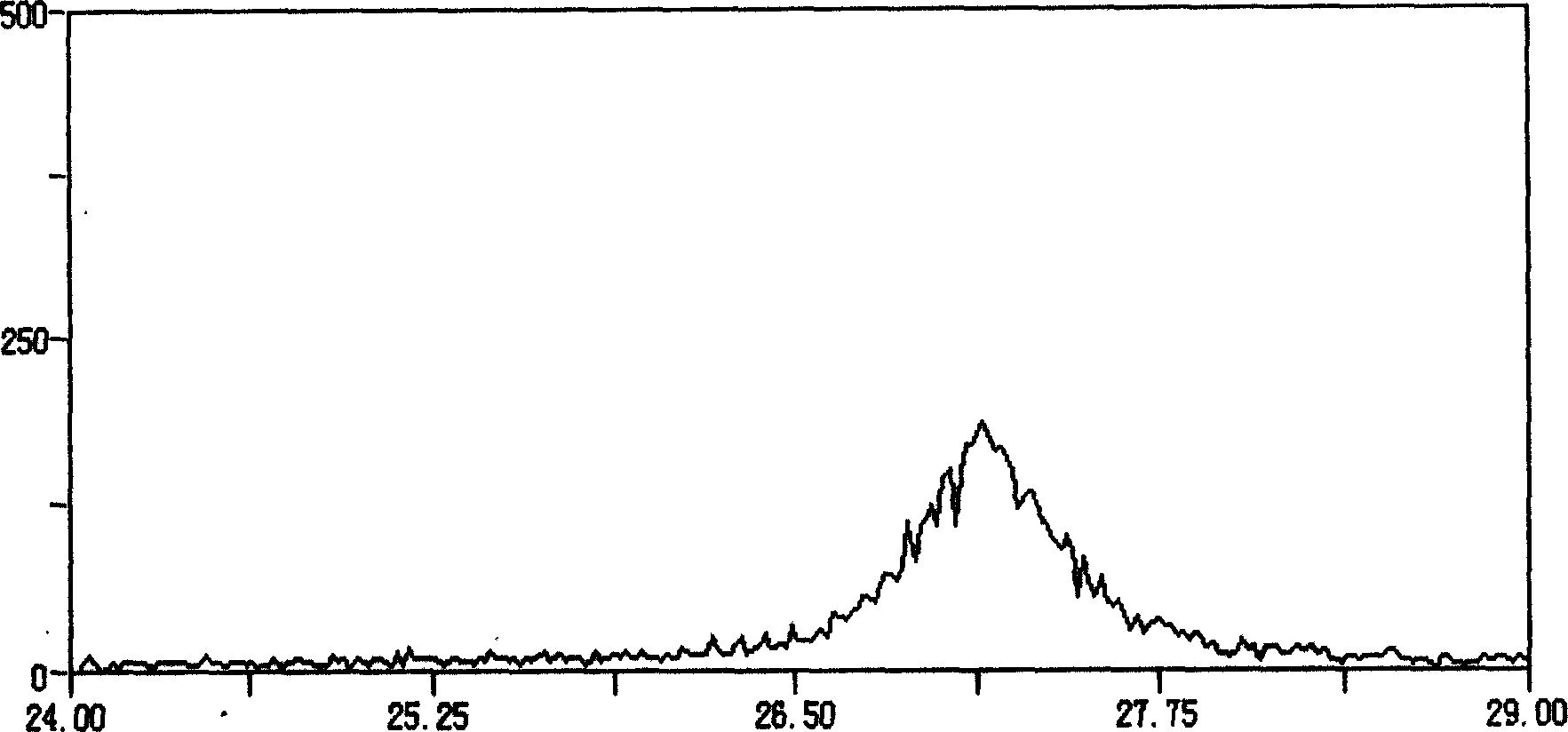

[0011] Take the concentration as 320g / l, the Fe contained in it 2 o 3 ≤0.01%, Fe 2 o 3 ≤0.003% metatitanic acid slurry 0.938m 3 And concentration is 48% liquid caustic soda 540Kg carries out heating caustic boiling reaction with the alkali-titanium ratio of 1.8:1, controls the reaction temperature between 108~116 ℃ and matures for 120 minutes, adds ion-free dilution and hydrolysis, washes with box filter press machine To NaOH contentfigure 1 As shown, the washing time and the rutile crystal content of the obtained samples are shown in Table 1, and the product quality of rutile titanium dioxide obtained by using the calcined seed crystal is compared with the national standard GB1706-93 as shown in Table 2.

Embodiment 2

[0013] Prepare the calcined seed crystal sample for the production of rutile titanium dioxide by the method of Example 1, the difference is that the concentration of the metatitanic acid slurry is 312g / l, and the volume is 0.962m 3 , the concentration of liquid alkali is 48%, the weight is 540Kg, and the ratio of alkali to titanium is 1.8:1. The washing time and the rutile crystal content of the obtained samples are shown in Table 1.

Embodiment 3

[0015] Prepare the calcined seed crystal sample for the production of rutile titanium dioxide by the method of Example 1, the difference is that the concentration of the metatitanic acid slurry is 305g / l, and the volume is 0.984m 3 , the concentration of liquid alkali is 49%, the weight is 510Kg, and the ratio of alkali to titanium is 1.7:1. The washing time and the rutile crystal content of the obtained samples are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com