Single purpose high-frequency induction welding wire heating apparatus for hot wire TIG welding

A high-frequency induction heating and welding wire technology, used in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of reduced hot wire efficiency, reduced magnetic deflection, and unsolved aluminum alloy welding problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

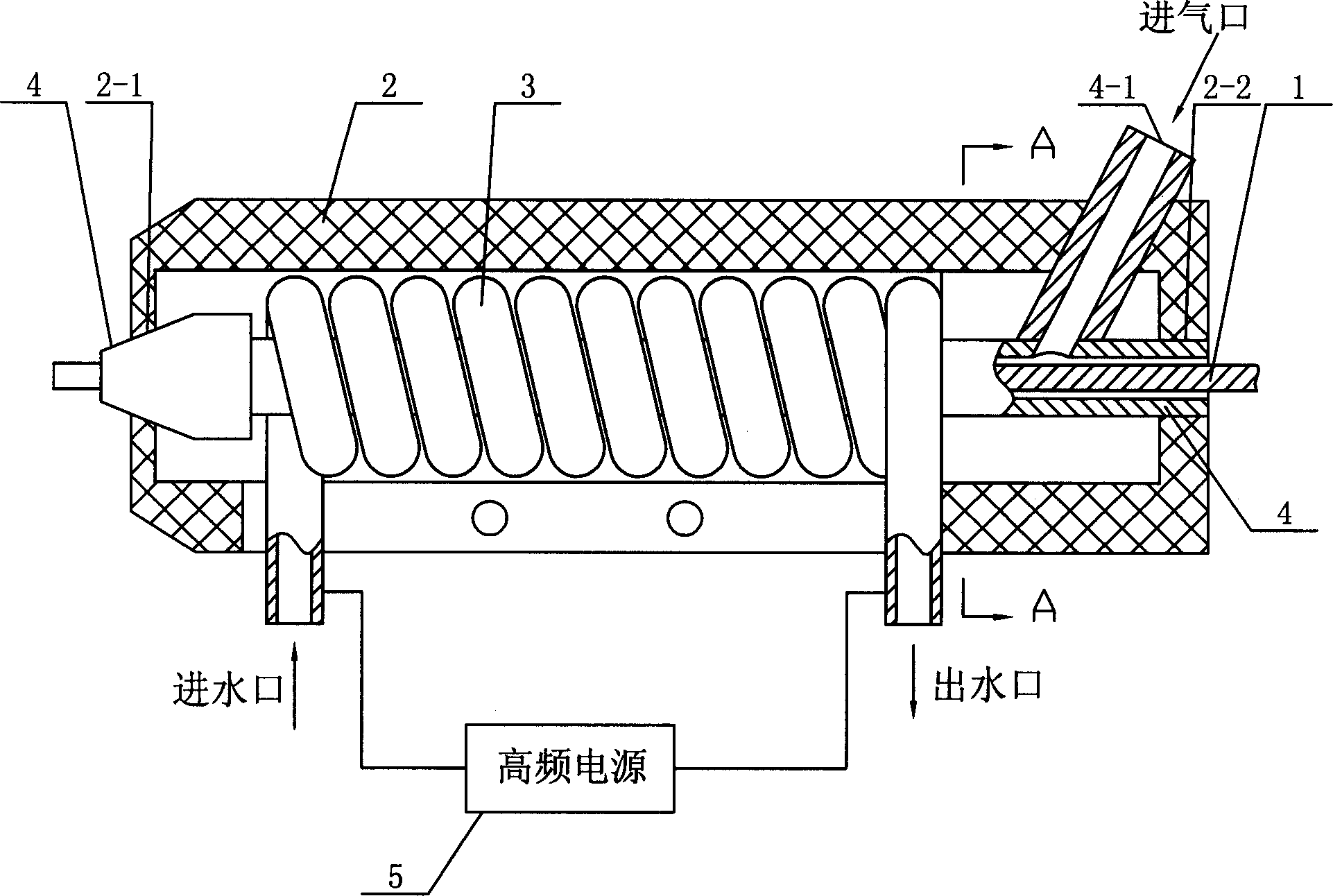

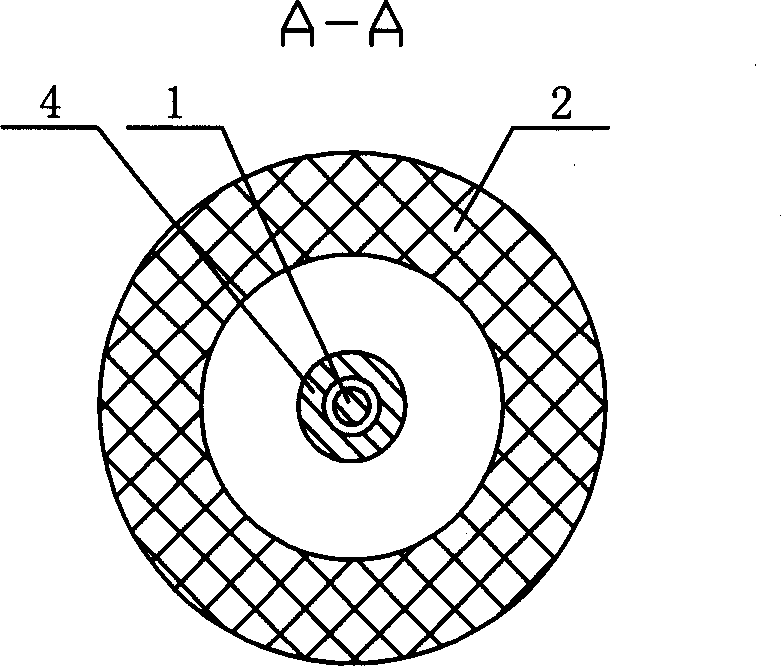

[0005] Specific implementation mode one: combine figure 1 , figure 2 Describe this embodiment, this embodiment is made up of welding wire 1, housing 2, induction coil 3, insulating conduit 4, high-frequency power supply 5; The axes of the insulating conduit 4 are coincident, the head and the end of the induction coil 3 are respectively connected to the two output terminals of the high-frequency power supply 5, and the two ends of the insulating conduit 4 pass through the holes 2-1 and hole 2 at both ends of the housing 2 respectively. -2, the welding wire 1 passes through one end of the insulating conduit 4 , and the outer circular surface of the welding wire 1 is slidably connected with the inner circular surface of the insulating conduit 4 . The selection parameters of the high-frequency power supply 5 are output power 15KVA, output frequency 50-500KHz, output current 200-600A.

specific Embodiment approach 2

[0006] Specific implementation mode two: combination figure 1 , figure 2 To illustrate this embodiment, the induction coil 3 in this embodiment is made of a copper pipe as a wire, and the first and last ports of the copper pipe are the water inlet and the water outlet of the cooling water respectively. Other compositions and connections are the same as in the first embodiment. In this embodiment, the heat generated on the induction coil 3 can be taken away by the circulating flow of cooling water, so that the induction coil 3 can work at a normal temperature.

specific Embodiment approach 3

[0007] Specific implementation mode three: combination figure 1 To describe this embodiment, an air port 4-1 is added at one end of the insulating conduit 4 in this embodiment, and the air port 4-1 is an air inlet port for the shielding gas. Other compositions and connections are the same as those in the second embodiment. In this embodiment, the welding wire 1 can be isolated from air so as not to be oxidized during welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com