Sofa with parts interchangeable, free assembly and its production method

A sofa and component technology, which is applied in the field of freely assembled sofas and their production, and interchangeable parts, can solve problems such as inability to freely assemble and form, and achieve the effects of producing and controlling defective product rates, saving costs, and improving the level of standardized production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

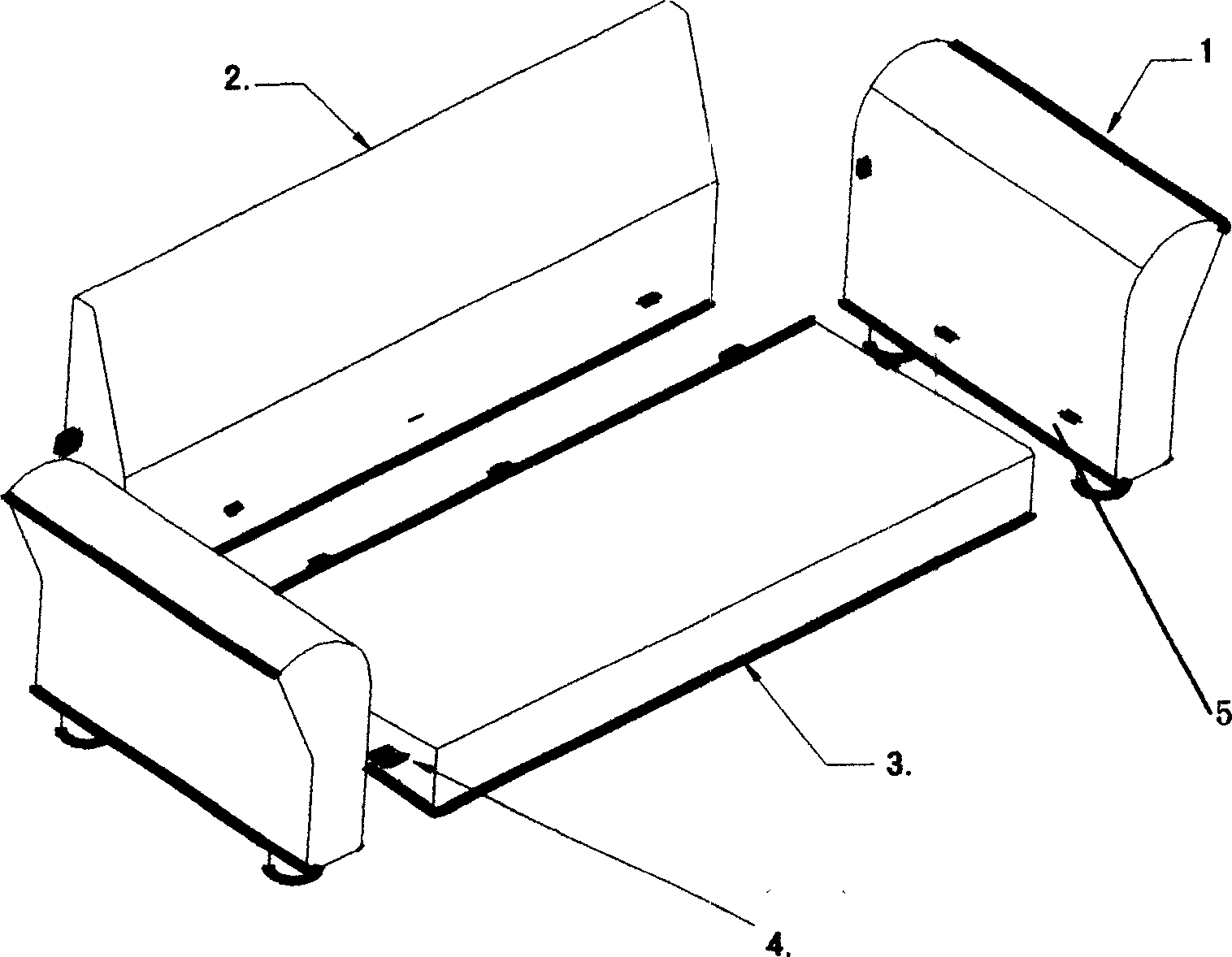

[0078] 1. Production of sofa armrest (1):

[0079] 1. Determine the connecting parts between the armrest (1) and the backrest (2) and the armrest (1) and the seat frame (3);

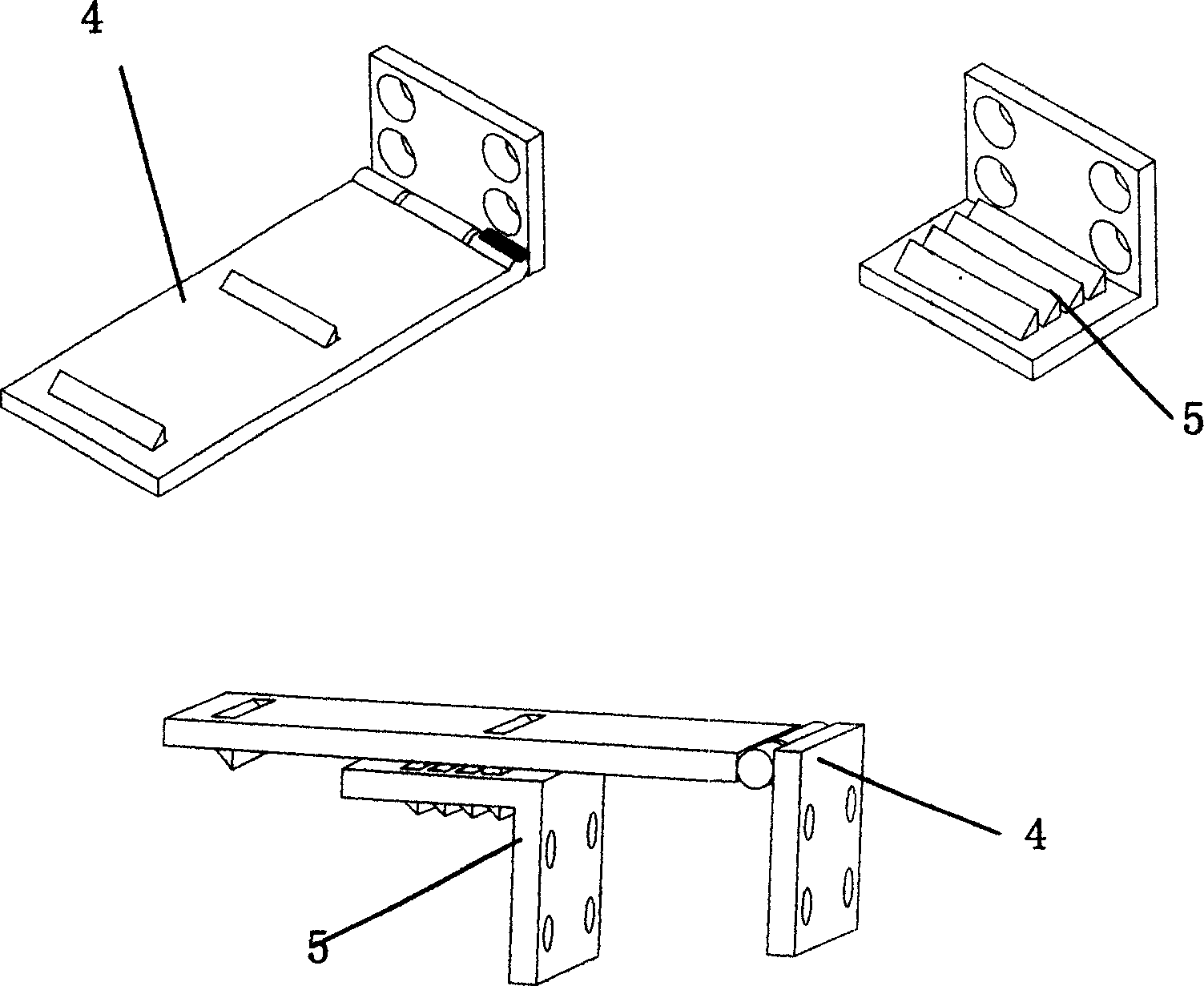

[0080] 2. Determine the specific positions of the fixed connectors (4, 5);

[0081] 3. Determine the components and their directions in the combined connectors that need to be used for each connection part;

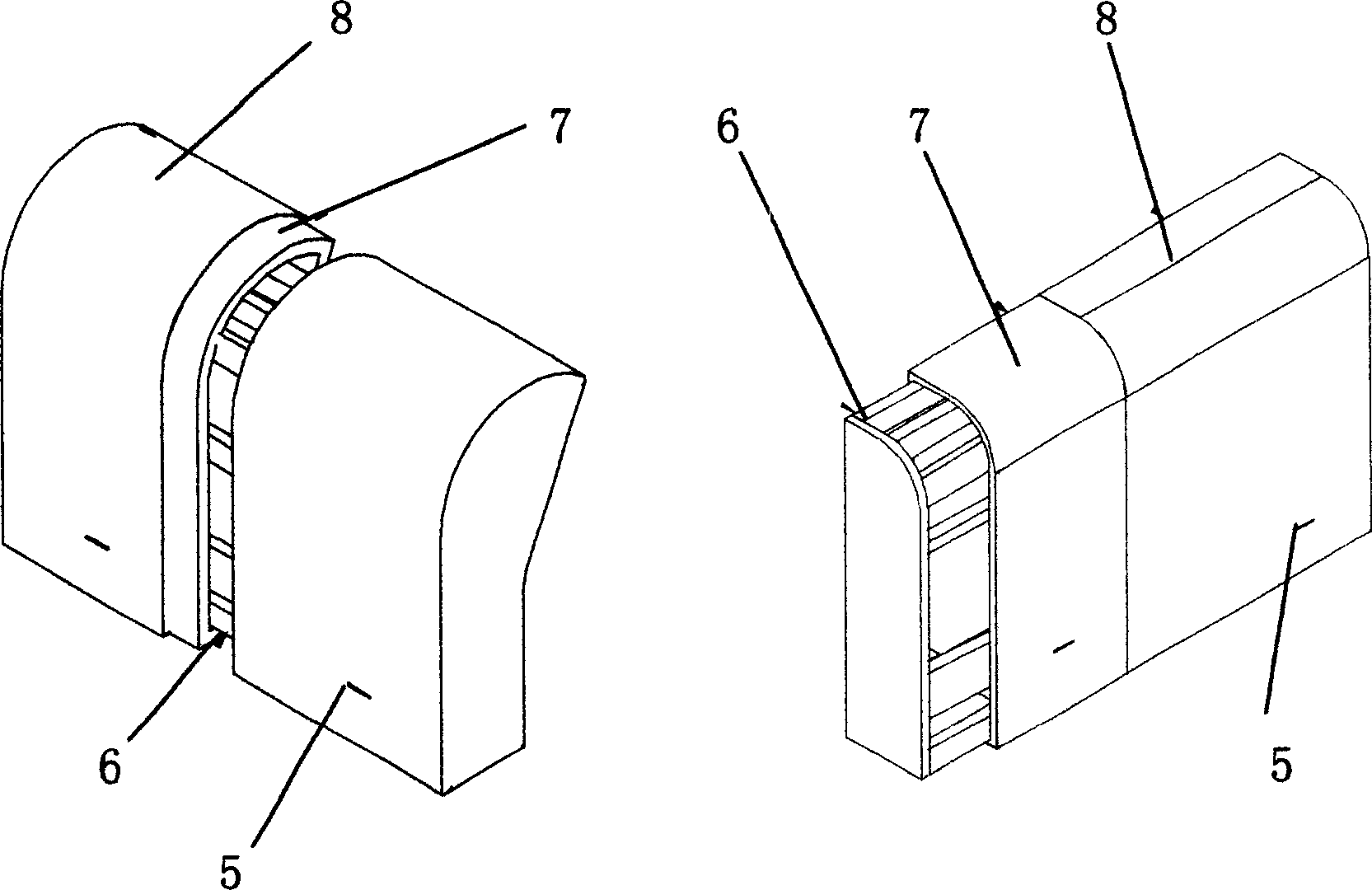

[0082] 4. Make the armrest backrest assembly mold A (12) of the joint between the armrest (1) and the backrest (2) and the seat frame (3);

[0083] 5. Make the positioning template C (14) of the combined connector for fixing the armrest seat frame and the armrest backrest, and determine the position of the connector on the template C (14);

[0084] 6. Place the framework material that needs to fix the combined connector under the template C (14), and then determine the position of the fixed connector on the framework material according to the positioning of the template C (14) and mark D (16) acco...

Embodiment 2

[0090] Fabrication of sofa back (2):

[0091] 1. Determine the connection between the backrest (2) and the armrest (1) and the backrest (2) and the seat frame (3);

[0092] 2. Determine the specific positions of the fixed connectors (4, 5);

[0093] 3. Determine the components and their directions in the combined connectors that need to be used for each connection part;

[0094] 4. Make the backrest armrest assembly mold A (12) of the joint between the backrest (2) and the armrest (1);

[0095] 5. Make the backrest frame assembly mold F (13) of the joint between the backrest (2) and the seat frame (3);

[0096] 6. Make a positioning template G (15) for fixing the combined connector of the backrest and armrest, and determine the position of the connector on the template G (15);

[0097] 7. Make a positioning template M (21) for fixing the combined connector of the backrest frame, and determine the position of the connector on the template M (21);

[0098] 8. Place the skele...

Embodiment 3

[0105] The making of sofa seat frame (3):

[0106] 1. Determine the connecting parts between the seat frame (3) and the armrest (1) and between the seat frame (3) and the backrest (2);

[0107] 2. Determine the specific positions of the fixed connectors (4, 5);

[0108] 3. Determine the components and their directions in the combined connectors that need to be used for each connection part;

[0109] 4. Making the frame and armrest assembly mold B (11) of the joint between the seat frame (3) and the armrest (1);

[0110] 5. Make the seat frame backrest assembly mold F (13) of the joint between the seat frame (3) and the backrest (2);

[0111] 6. Make the positioning template K (18) of the combined connector of the fixed armrest frame, and determine the position of the connector on the template K (18);

[0112] 7. Place the framework material that needs to fix the combined connector under the horizontal plate K (18), and then determine the position of the fixed connector on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com