Space solar cell string non-contact pressing method

A solar cell, non-contact technology, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of crushing of cells, difficulty in ensuring the relative spacing error of cell strings, and low efficiency, so as to reduce offset, The effect of improving the quality of cloth sticking and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] The specific steps of the method are as follows;

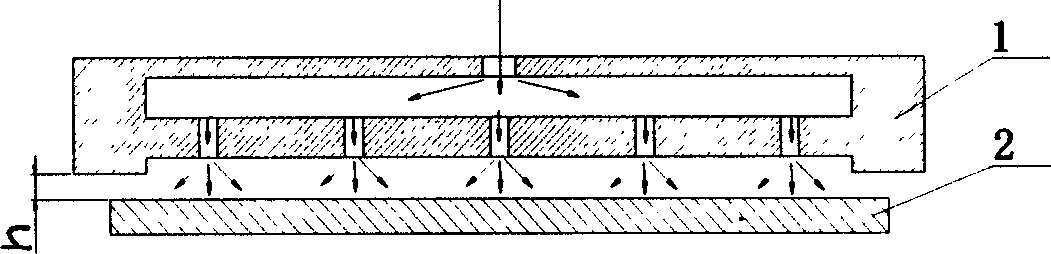

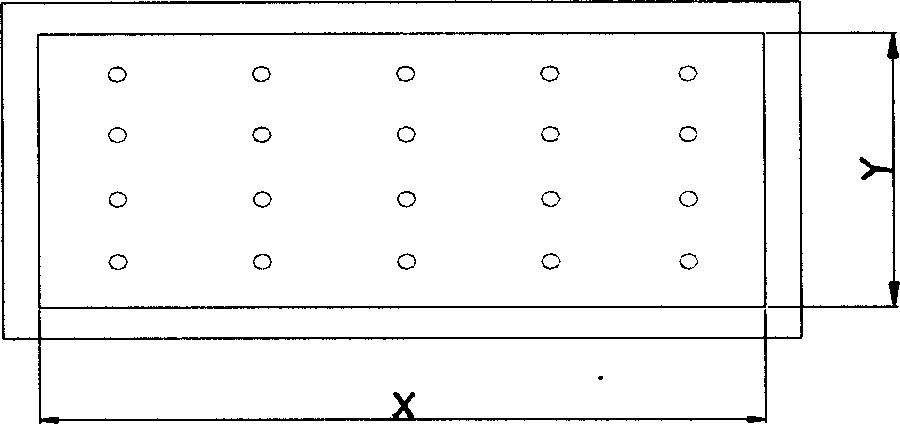

[0028] 1. The embodiment of the present invention is aimed at a string of solar battery strings connected in series with solar battery pieces with a length of 40 mm and a width of 20 mm, using the following method: figure 1 In the shown pressure device, the inside of the pressure device 1 is a gas storage chamber, the upper end of the gas storage chamber has an air inlet, and the lower end of the gas storage chamber is evenly arranged with small air outlet holes, and there are 20 (5×4) holes for each solar cell ¢0.7mm air outlet hole.

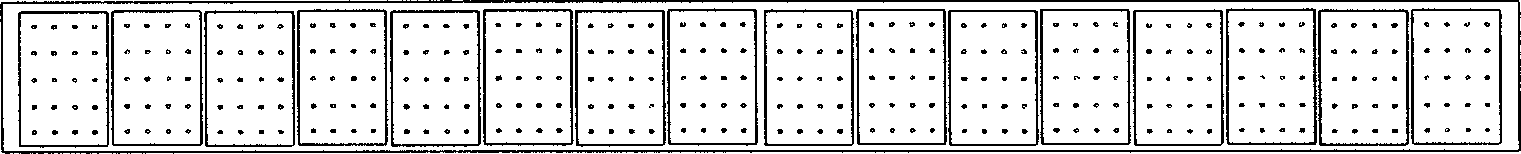

[0029] For a single space solar cell, the length X and width Y of the pressurizing space of the pressurizing device are smaller than the length and width of the space solar cell, such as figure 2 shown. For solar cell strings, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com