Process for extracting lignin by acid separation

A technology of acid analysis lignin and extraction process, which is applied in the field of acid analysis lignin extraction process, can solve problems such as difficulties, lack of detail and specificity, and unexplained static removal efficiency of fiber sludge, etc., to achieve large processing capacity and one-time investment small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

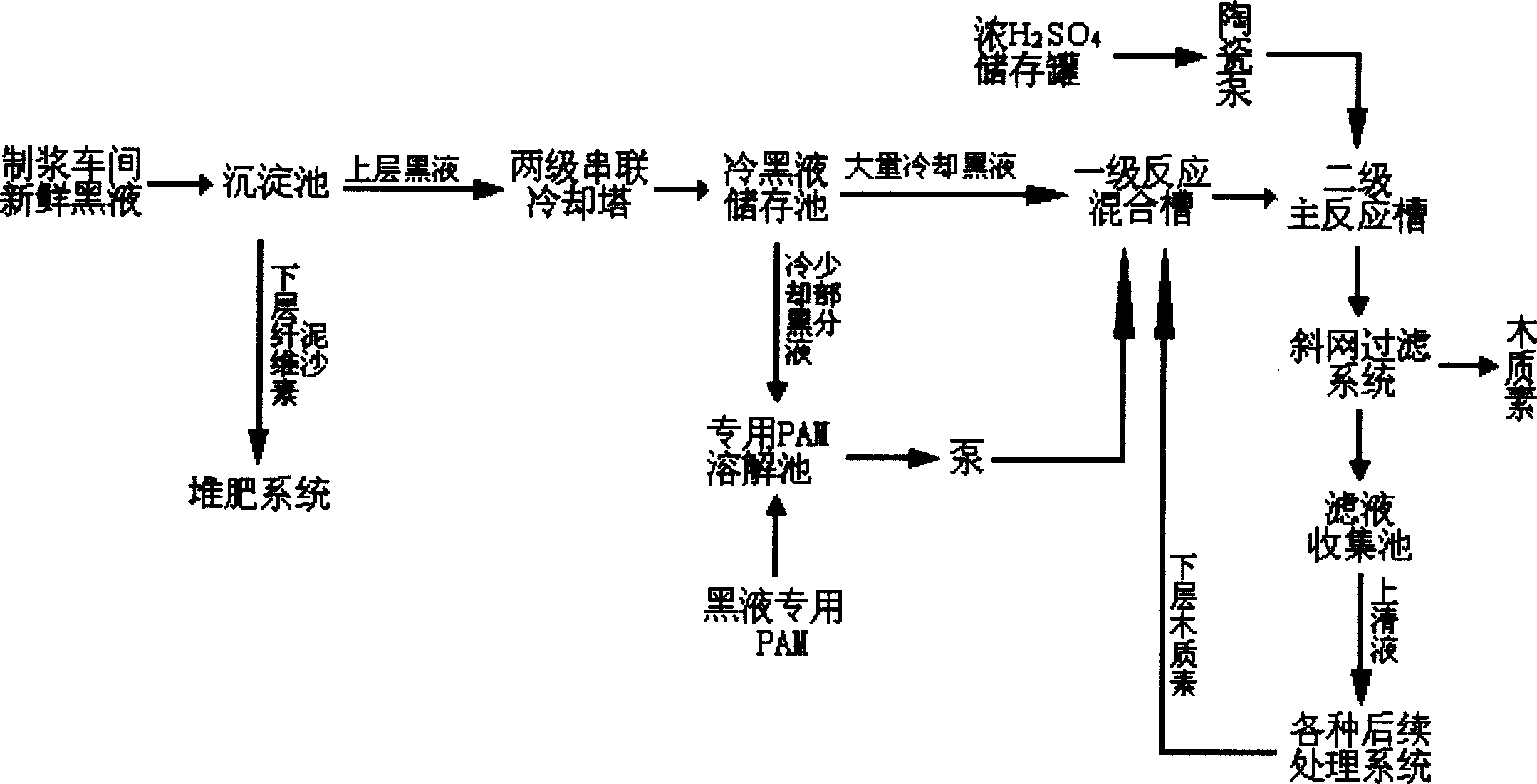

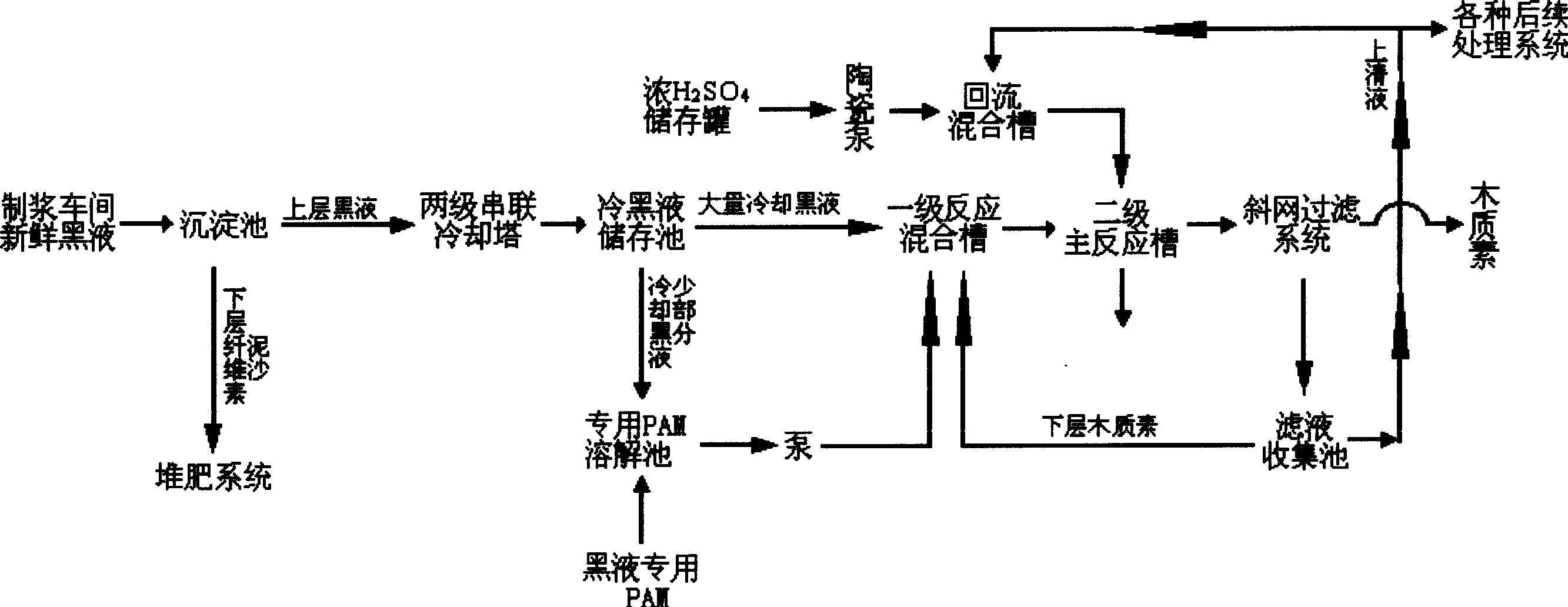

Method used

Image

Examples

Embodiment 1

[0048] Put 500 cubic meters of black liquor in the pool for 10 hours to allow the fiber mud and sediment to settle, and the upper layer of black liquor enters the two-stage series cooling tower to cool down, so that the temperature of the black liquor drops to 35°C; the cooled black liquor enters the Collect in the storage tank, get 50 square meters of black liquor as solvent, add molecular weight to it and be 15 million polyacrylamide (Gongyi City Lanxing Water Purification Material Factory, APAM, white granule) 50kg, when adding, in the vertical direction of black liquor inlet Add the black liquor evenly from the top, mix evenly in the special dissolution tank, pour it into the folded plate reaction tank through the metering pump, merge with another part of the black liquor, and after uniform mixing, enter the secondary main tank with a four-stage stepped drop mixing system Reaction tank; at the same time as adding, add H with a concentration of 93% to the secondary main reac...

Embodiment 2

[0050] Put 1,000 cubic meters of black liquor in the pool for 8 hours to allow the fiber mud and sediment to settle, and the upper layer of black liquor enters the two-stage series cooling tower to cool down, so that the temperature of the black liquor drops to 30°C; the cooled black liquor enters the Collect in the storage tank, get 200 square meters of black liquor as solvent, add molecular weight to it to be 10 million polyacrylamide (Gongyi City Lanxing Water Purification Material Factory, APAM, white granule) 120kg, when adding, in the vertical direction of black liquor inlet Add the black liquor evenly from the top, mix evenly in the special dissolution tank, pour it into the folded plate reaction tank through the metering pump, merge with another part of the black liquor, and after uniform mixing, enter the secondary main tank with a four-stage stepped drop mixing system Reaction tank; at the same time as adding, add H with a concentration of 95% to the secondary main re...

Embodiment 3

[0054] Put 1,000 cubic meters of black liquor in the pool for 12 hours to allow the fiber mud and sediment to settle, and the upper layer of black liquor enters the two-stage series cooling tower to cool down, so that the temperature of the black liquor drops to 20°C; the cooled black liquor enters the Collect in the storage tank, take 300 square meters of black liquor as a solvent, add 200kg of polyacrylamide (Yixing Angel Synthetic Chemical Co., Ltd.) with a molecular weight of 20 million to it, and add evenly with the black liquor above the vertical direction of the black liquor inlet , mixed evenly in the special dissolution tank, poured into the folded plate reaction tank through the metering pump, merged with another part of the black liquor, after uniform mixing, entered the secondary main reaction tank with a four-level stepped drop mixing system; while adding , adding 100% H to the secondary main reaction tank through a ceramic pump 2 SO 4 ; The inlet and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com