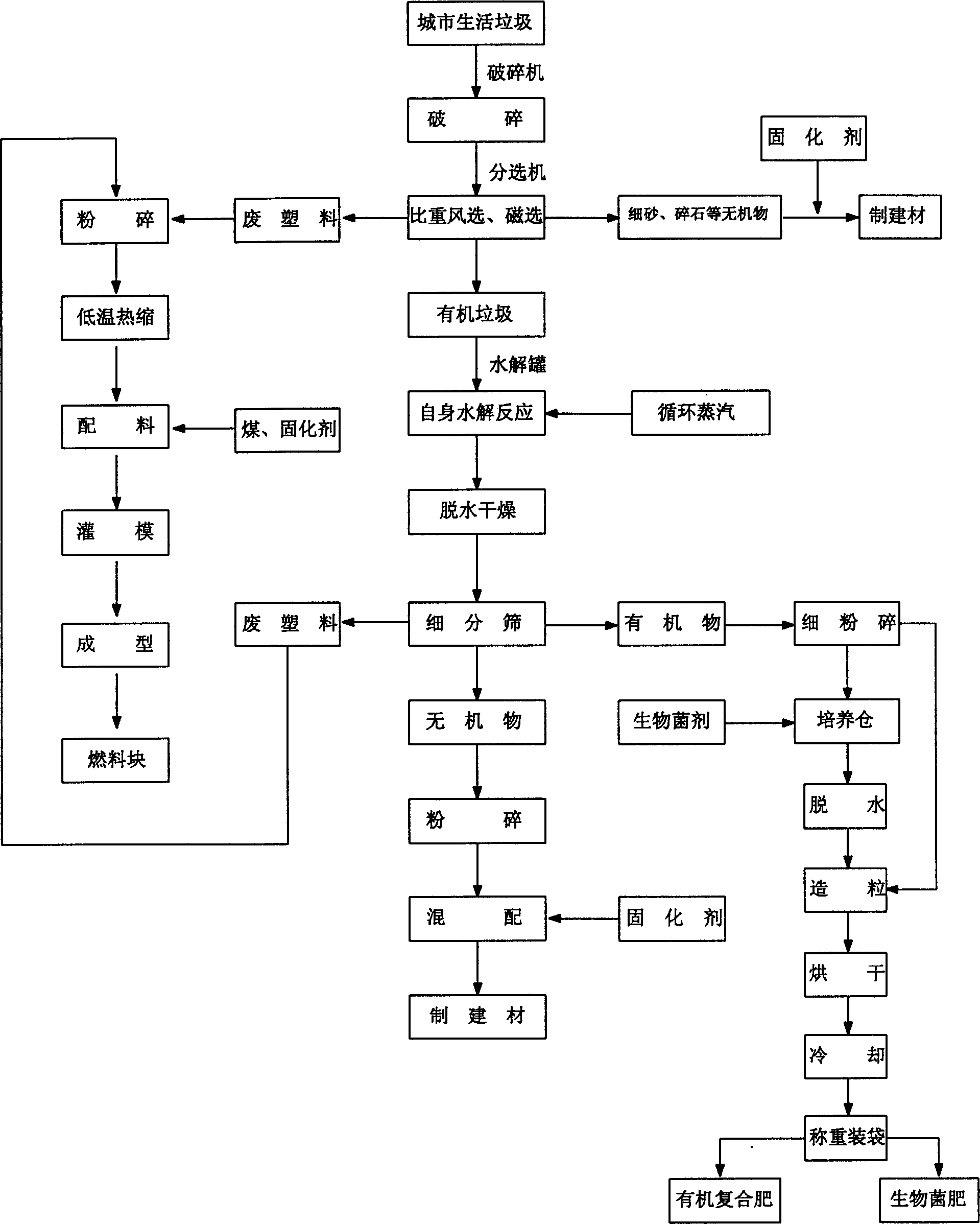

Life refuse treating process

A domestic garbage and treatment process technology, applied in the field of solid waste treatment, can solve problems such as high labor intensity, high operating cost, and secondary pollution of the environment, and achieve the effects of reducing labor intensity, avoiding secondary pollution, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] As shown in the figure, municipal domestic waste is crushed with a crusher, and then enters a sorter for specific gravity air separation and magnetic separation, and is divided into three categories: inorganic matter (mainly fine sand, gravel, etc.), organic waste, and waste plastic. Inorganic substances are sent to the building material system, and curing agents are added to make building materials; waste plastics are sent to the waste plastic treatment system; organic waste is sent to the hydrolysis tank for self-hydrolysis reaction, and the hydrolysis and dehydration are carried out at the same time by circulating steam, which is controlled at The reaction was carried out for 3.3 hours at a pressure of 8 to 10 MPa and a temperature of 150 to 200°C. Continue dehydration after hydrolysis until the water content is less than 20%. After the dehydration is completed, it is sprayed and dried, and then subdivided and sieved to obtain inorganic matter, organic matter and was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com