Grinding roller

A technology of grinding rollers and teeth, applied in the field of grinding rollers, can solve the problem of not meeting the crushing requirements of raw materials for koji making, and achieve the effects of reducing energy consumption, increasing extrusion force, and reducing shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

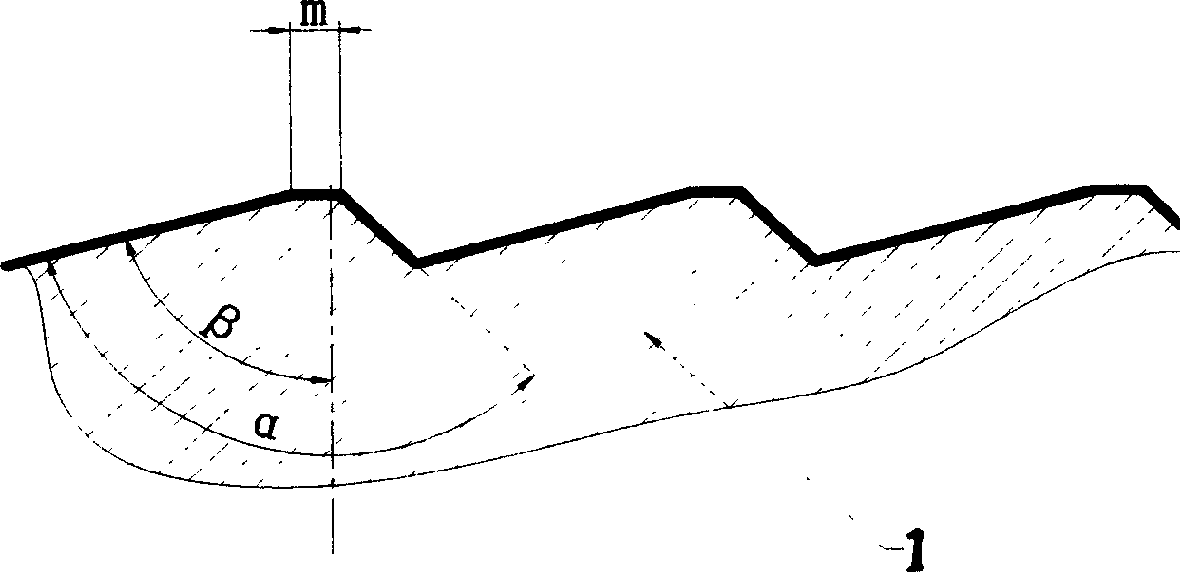

[0024] Example: such as Figure 1 to Figure 5 As shown, the tooth angle α of the grinding teeth on the surface of the roller body 1 of the grinding roller of the present invention is 120°, the obtuse angle β is 75°, the length ratio of the obtuse surface / front surface is 1.67, the number of teeth is 4.72 teeth / cm, and the addendum is wide The m is 0.6mm, and the slope of the roller body is 5°40′. The raw material grain for koji making processed by this grinding roller is in the block shape of "gardenia petals", which satisfies the crushing of the raw material grain for koji making. Require.

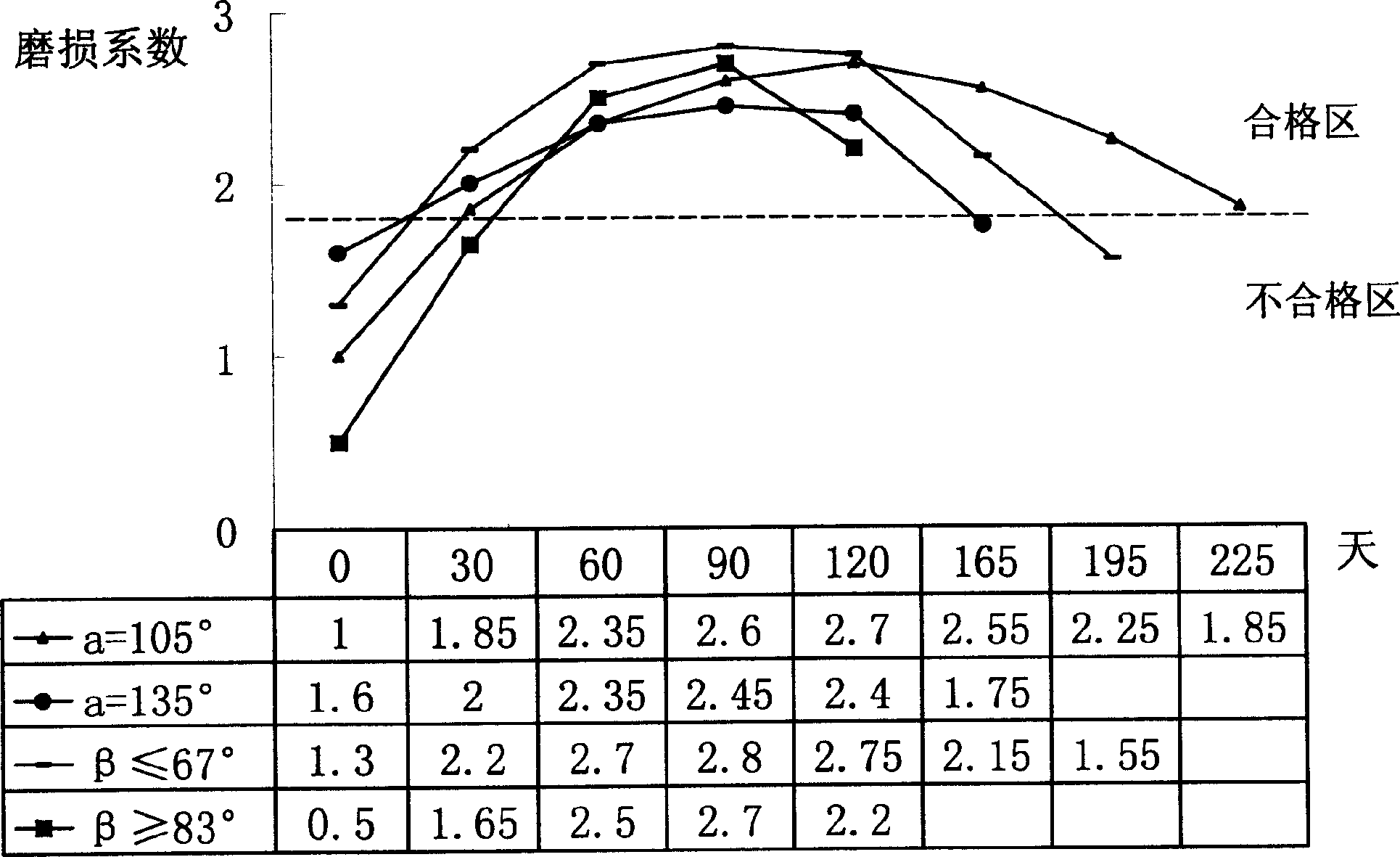

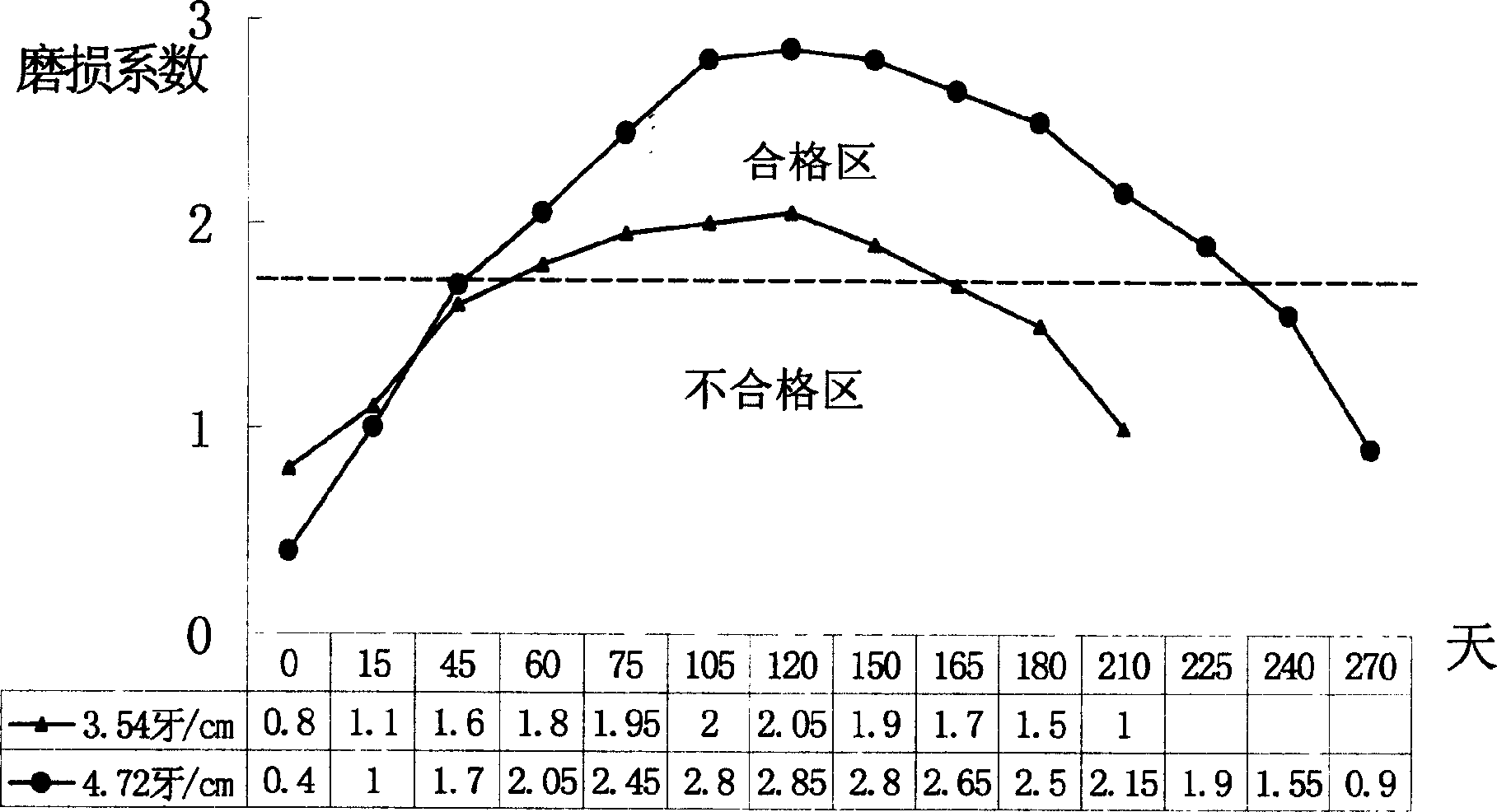

[0025] Use the above-mentioned grinding roller of the present invention to process the raw material grain for koji making and the experimental data and curves of comparison on the three indicators of crushing quality, wear resistance and energy consumption with the existing grinding roller, see Figure 5 , the tooth angle α of the grinding teeth of the existing grinding roller is 90°, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com