Direct current sensor

A DC current and sensor technology, applied in the direction of measuring current/voltage, instruments, measuring electrical variables, etc., can solve the problems of limiting the application and promotion of magnetic modulators, complex structure, low coercive force, etc., and improve the open-loop output characteristics , Good interchangeability, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

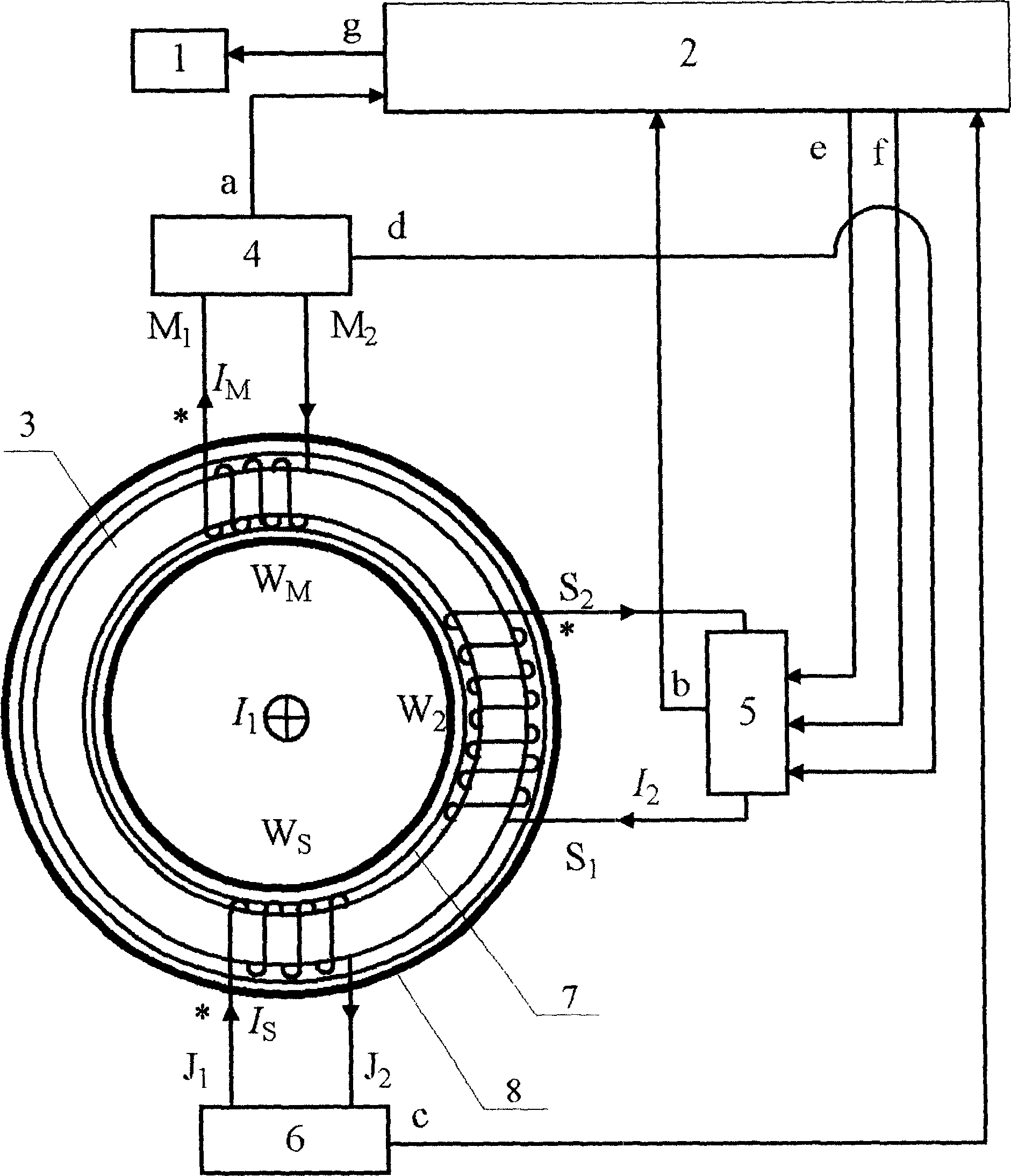

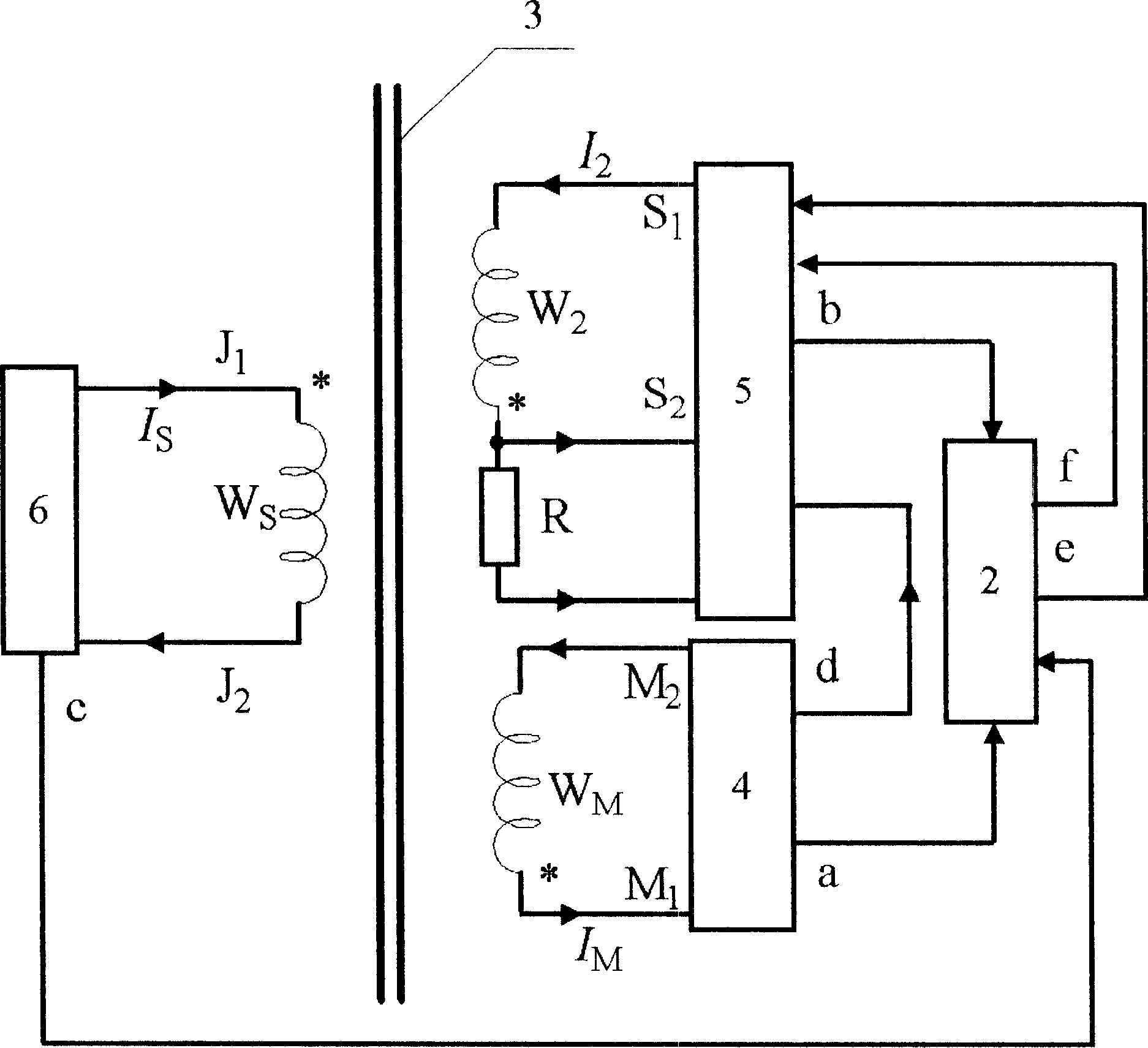

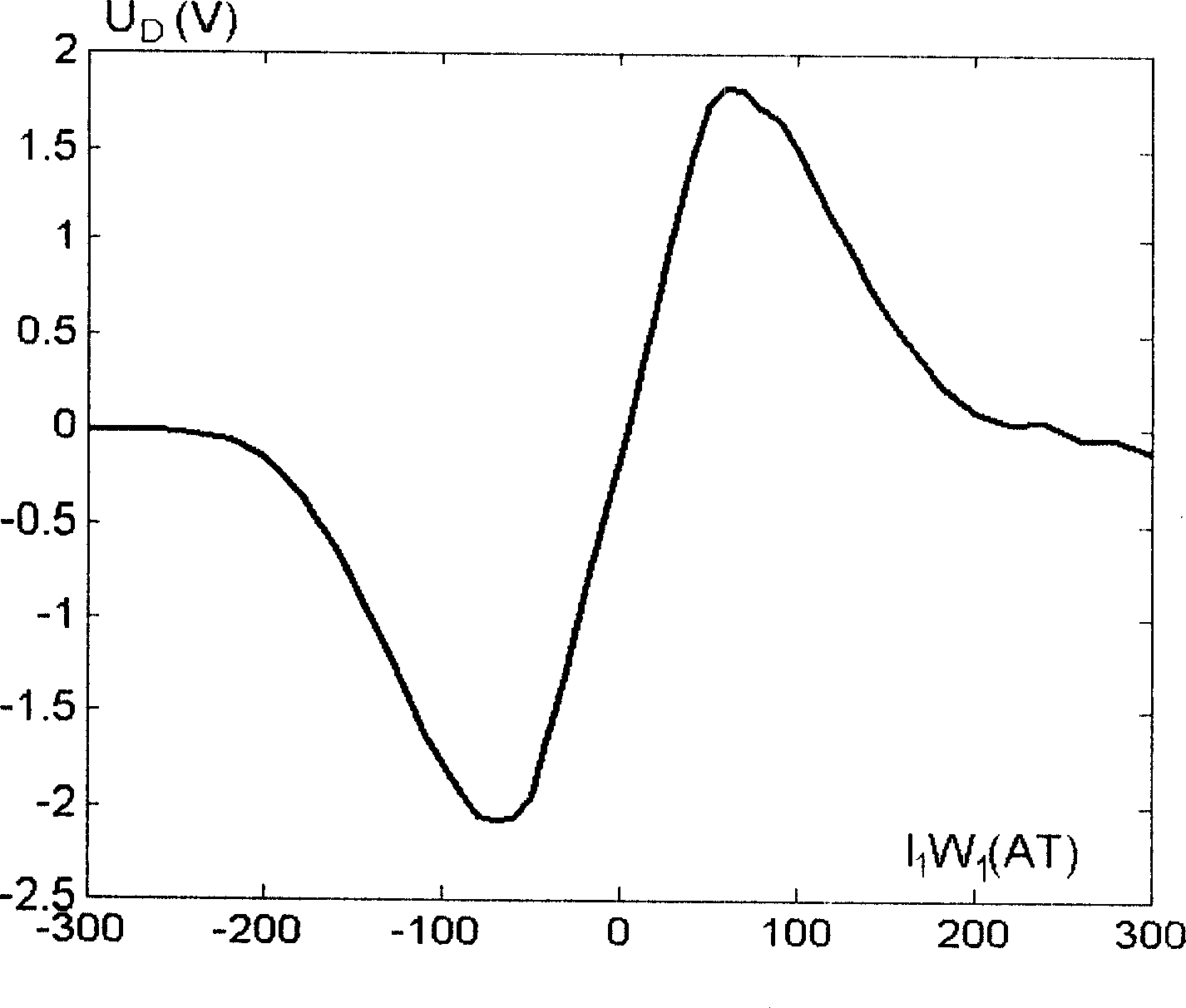

[0027] Depend on figure 1 , figure 2 Shown, W M To detect the coil, the current flowing through the coil is I M , W 2 is the feedback winding, the current flowing in this winding is I 2 , W S To excite the winding, the current flowing in this winding is I S , 1 is the monitor, 2 is the computer, 3 is the ring core, 4 is the detection coil W M processing circuit, 5 is the feedback winding W 2 processing circuit, 6 is the excitation winding W S Processing circuit, 7 is the shielding layer of the sensor, 8 is the outer protective ring of the sensor, I 1 is the measured DC, * indicates the detection coil W M , excitation winding W S and the feedback winding W 2 end of the same name.

[0028] Wind the excitation winding W on the ring core 3 S , Feedback winding W 2 and detection coil W M , at the detection coil W M The two ends of the processing circuit 4, in the feedback winding W 2 The two ends of the processing circuit 5, in the excitation winding W SThe two-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com