Method for exciting light for optical amplification medium fiber, structure for emitting excited light into optical amplification medium fiber optical fiber amplifier, and uses

A technology of optical amplification and excitation light, applied in the fields of fiber lasers, fiber amplifiers and fiber lasers, it can solve the problems of inability to output laser light, transparency damage, structure burning, etc., so as to improve the incidence efficiency, reduce costs, and reduce parts The effect of the number of pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

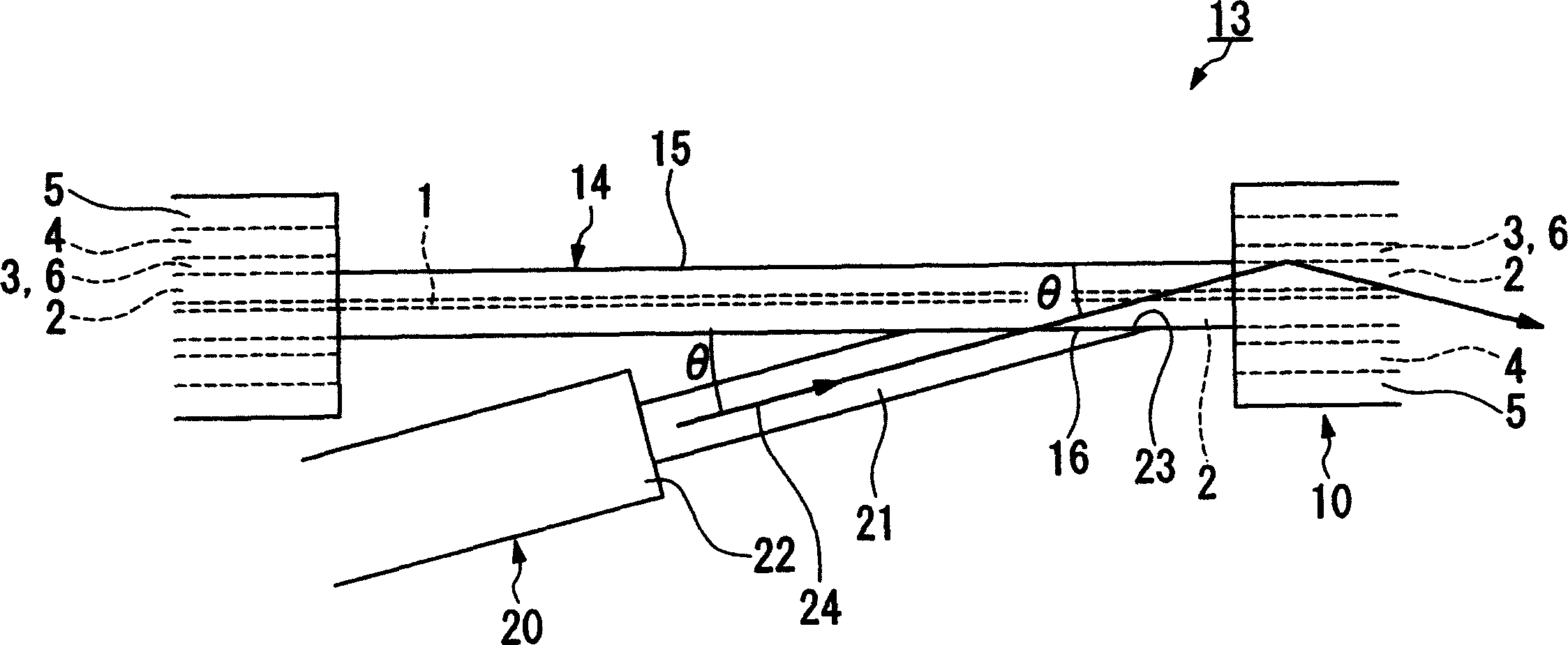

[0072] Hereinafter, the present invention will be described in detail based on embodiments.

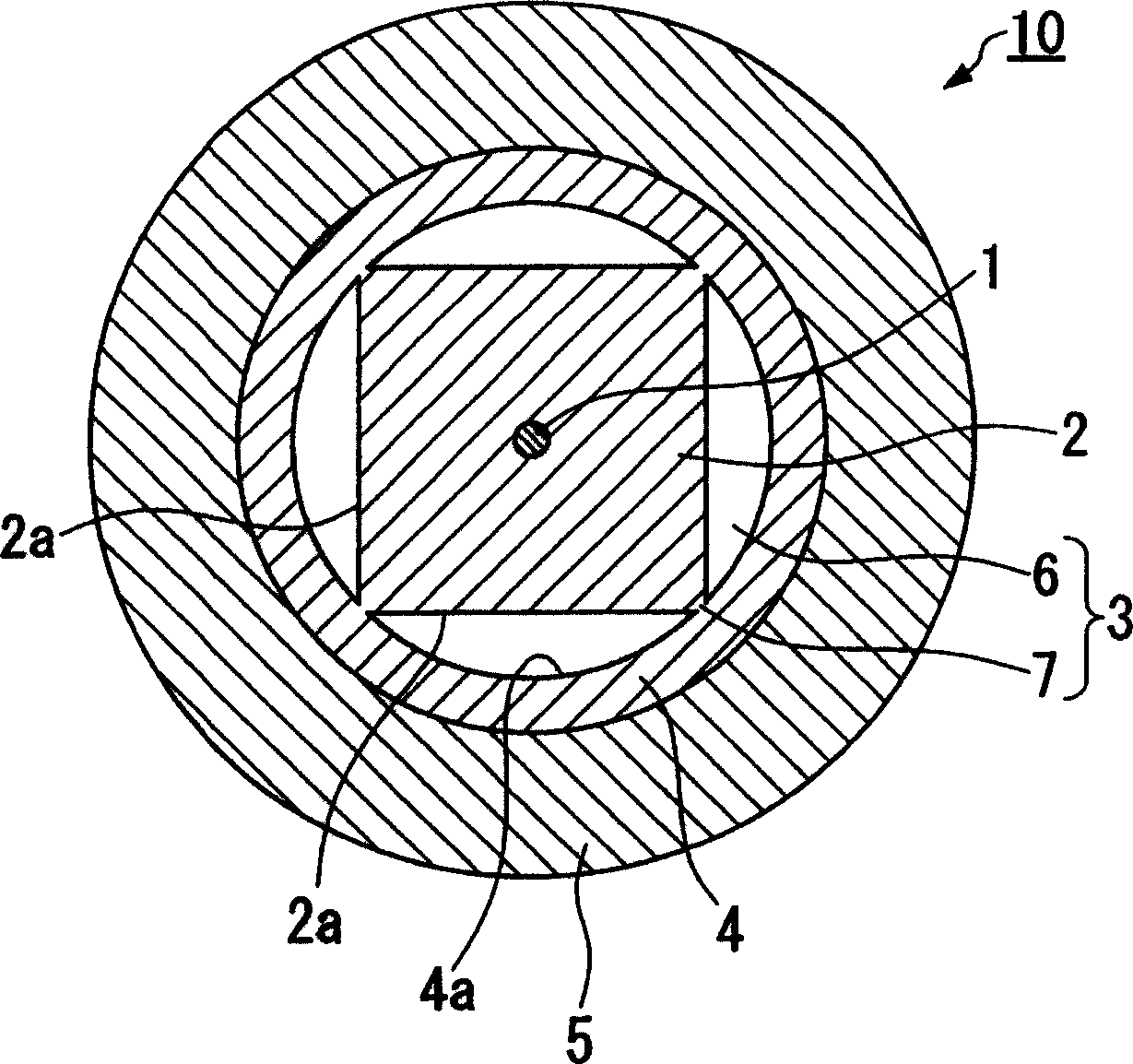

[0073] figure 1 It is a schematic configuration diagram showing an embodiment of an excitation light incident structure (hereinafter often simply referred to as an "excitation light incident structure") to an optical amplifying medium fiber of the present invention. in addition, figure 2 yes means figure 1A cross-sectional view of the light-amplifying dielectric fiber used in the excitation light incident structure shown.

[0074] Such as figure 2 As shown, the optical amplifying dielectric fiber 10 used in the excitation light incident structure of this embodiment has: a core 1 to which a rare earth element is added, an inner cladding 2 provided on the outer periphery of the core 1, and an inner cladding 2 on the inner cladding. A void layer 3 formed on the periphery of the layer 2 , an outer cladding layer 4 provided on the periphery of the void layer 3 , and a cover layer 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com