Enclosed return circuit hydraulic beam-pumping unit utilizing frequency conversion technology

A closed-loop, frequency conversion technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of low efficiency, poor self-control, and high energy consumption, and achieve flexible system control, improve efficiency, reduce The effect of installed power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

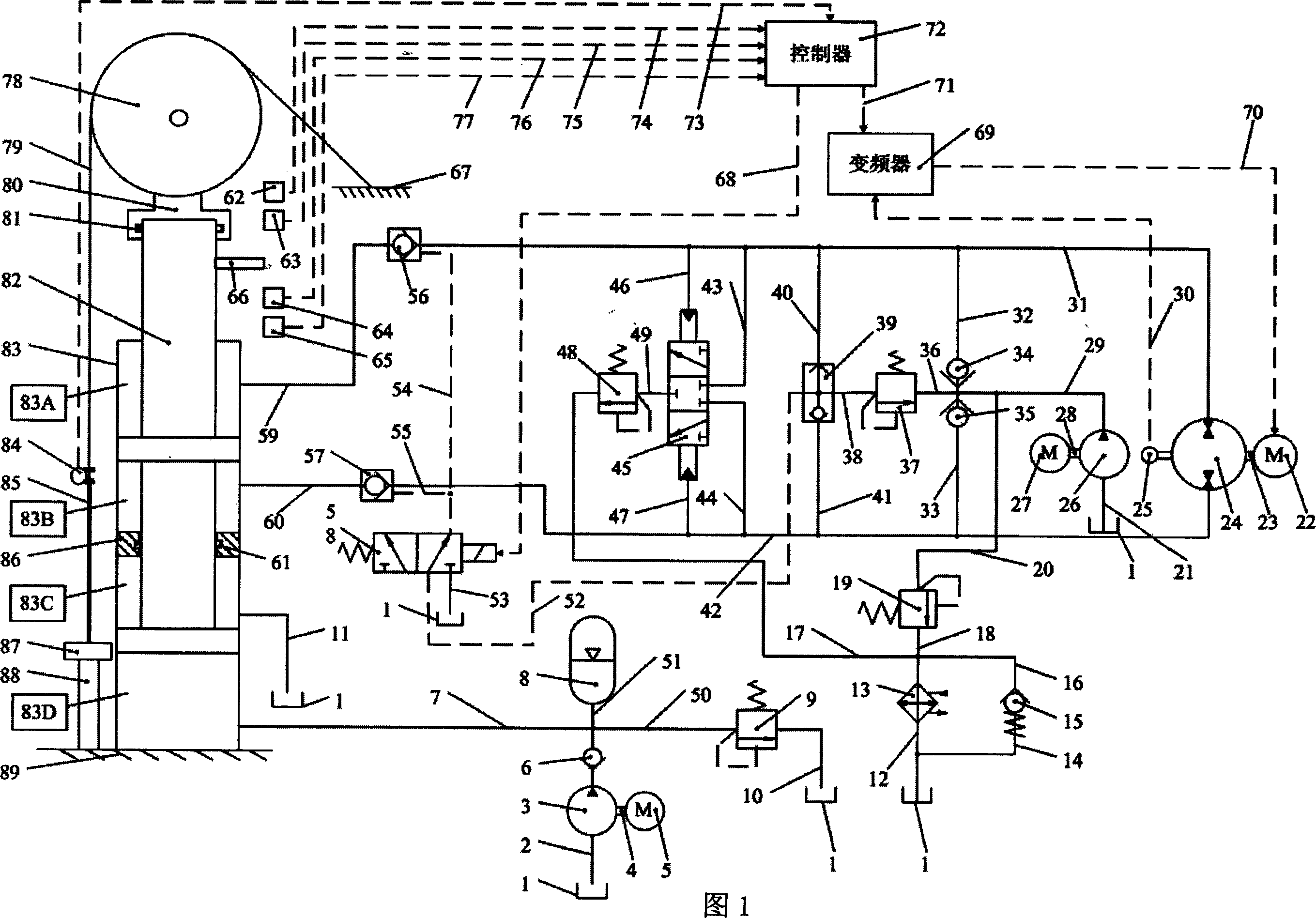

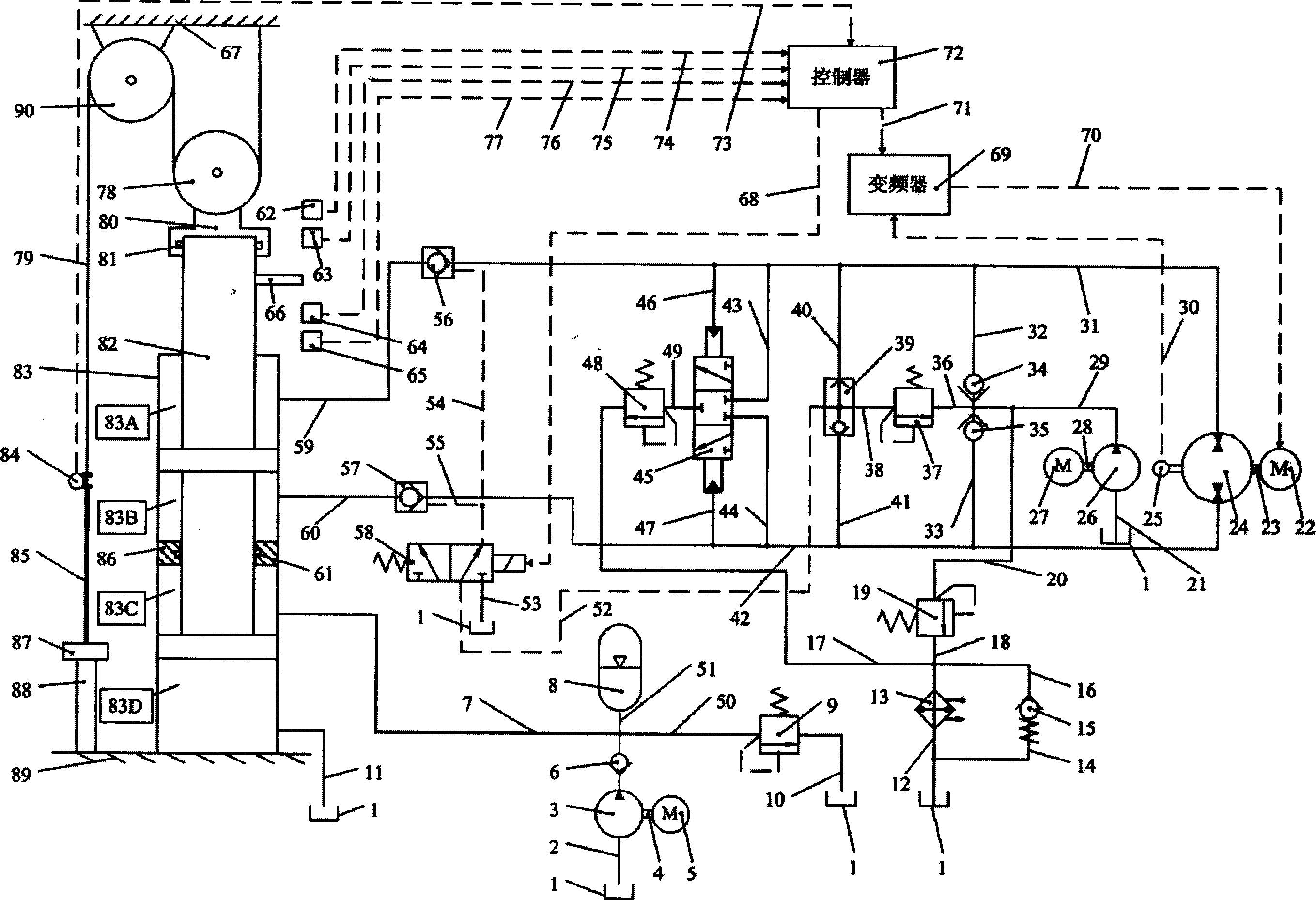

[0024] As shown in Figure 1, the present invention includes:

[0025] Mechanical part: the upper and lower pistons of the hydraulic cylinder plunger 82 match the hydraulic cylinder 83, a hydraulic cylinder partition 86 is installed between the two pistons, the fixed pin 81 and the roller bracket 80 connect the end of the hydraulic cylinder plunger 82 with the movable pulley 78 , the movable pulley 78 is wound with a wire rope 79, one end of the wire rope 79 is connected to the fixed base frame 67, the other end is connected to the polished rod 85 of the pumping unit, and the polished rod 85 of the pumping unit is connected to the oil extraction pipe 88 through the christmas tree 87.

[0026] Hydraulic part: One end of the two-way pump / motor 24 is connected to the oil inlet of the first hydraulic control check valve 56 through the hydraulic pipeline 31, and then connected to the upper piston oil chamber 83A of the hydraulic cylinder 83 through the hydraulic pipeline 59, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com