Piezoelectric driving element having multilayer piezoelectric composite membrane structure

A technology of piezoelectric drive and piezoelectric composite, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric devices/electrostrictive devices, electrical components, etc., can solve the problem that the output displacement of piezoelectric film drivers is lower than Problems such as micron level and working voltage limitation achieve the effect of large output torque, improved output displacement and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

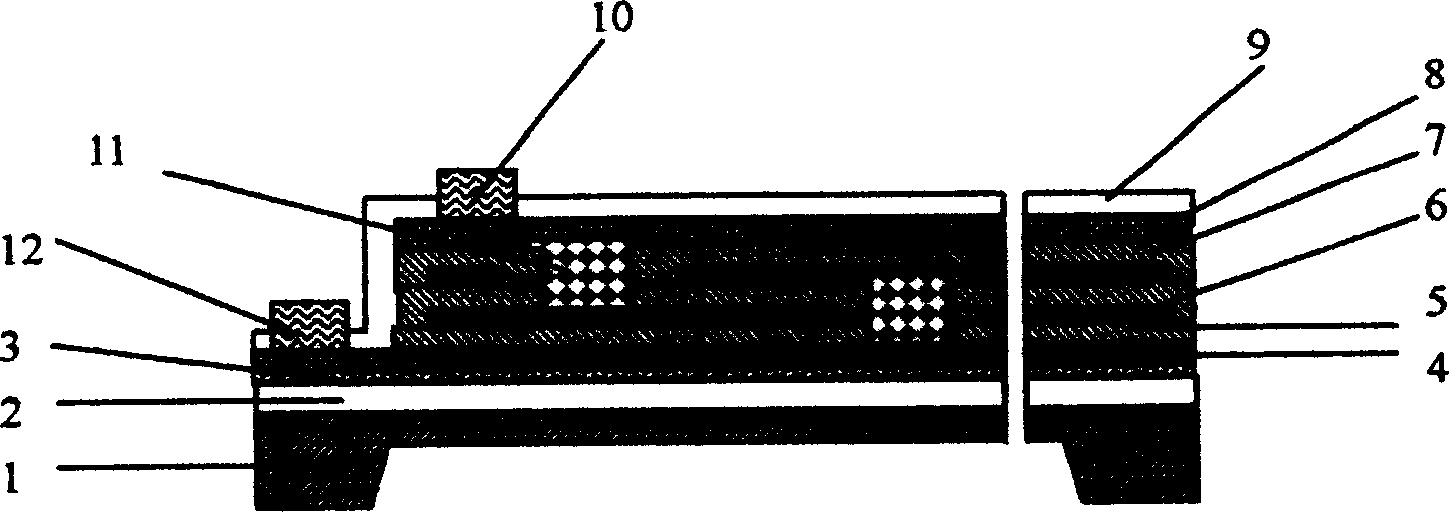

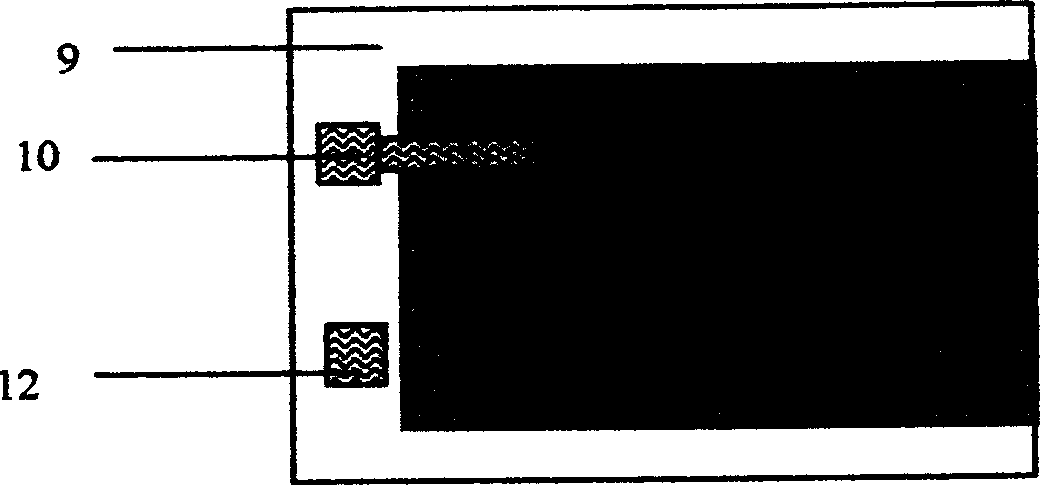

[0028] Preparation of Multilayer Composite Film Si / SiO 2 / Ti / Pt / PZT / Pt / PZT / Pt / PZT / Pt / SiO 2 / Al, the thickness of each layer is 40000 / 800 / 50 / 200 / 120 / 20 / 120 / 200 / 120 / 50 / 300 / 1000 nanometers from bottom to top, and the size of the cantilever beam is 600 microns×60 microns.

Embodiment 2

[0030] Preparation of Multilayer Composite Film Si / SiO 2 / Ti / Pt / PZT / Pt / PZT / Pt / PZT / Pt / SiO 2 / Al, the thickness of each layer is 10000 / 800 / 50 / 200 / 120 / 20 / 120 / 20 / 120 / 50 / 300 / 1000 nanometers from bottom to top, and the size of the cantilever beam is 600 microns×100 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com