Fast vertical/horizontal type boring and milling automatic processing center

A technology of automatic machining and high-speed milling, which is used in metal processing equipment, manufacturing tools, boring/drilling, etc., to achieve the effects of high machining accuracy, high production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

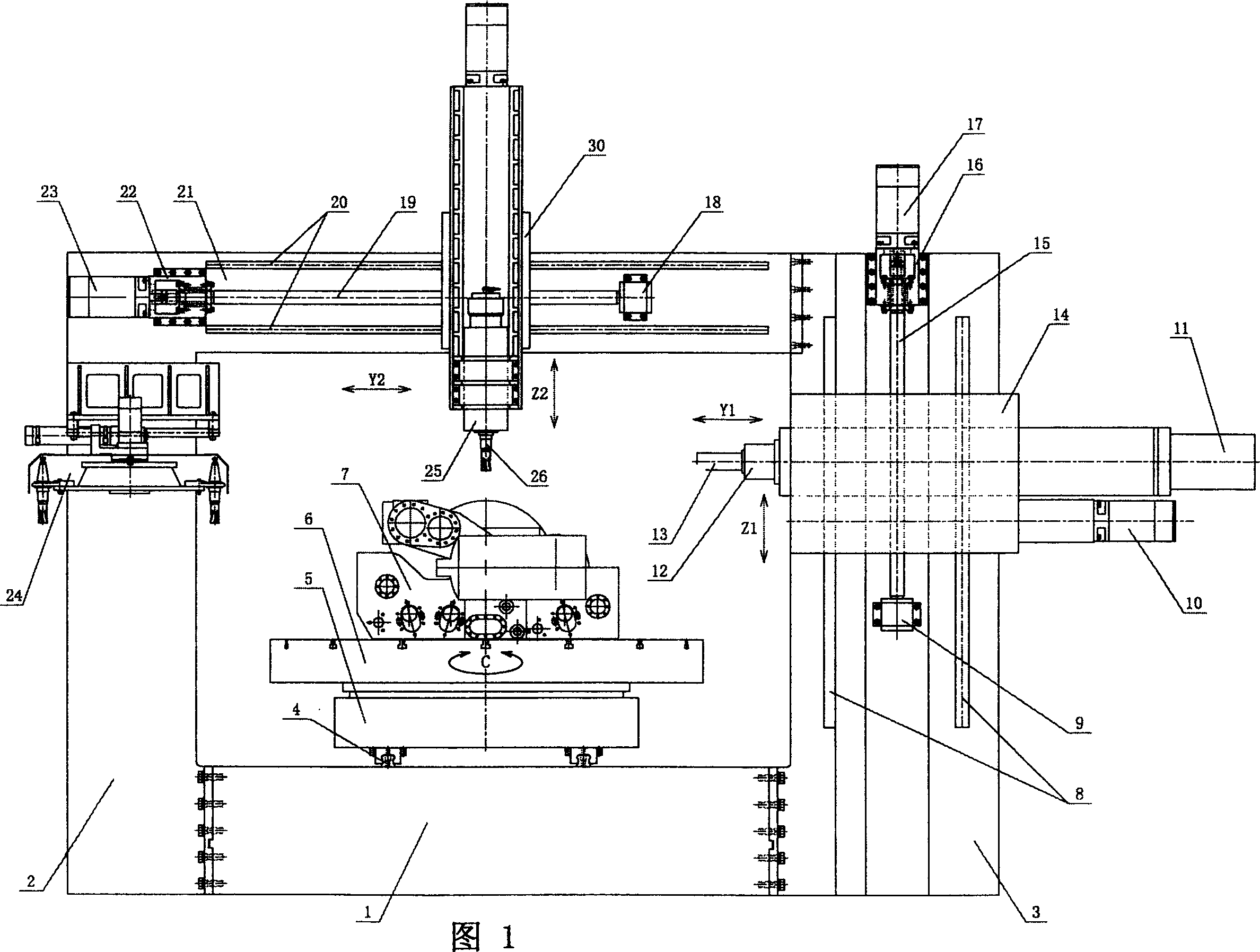

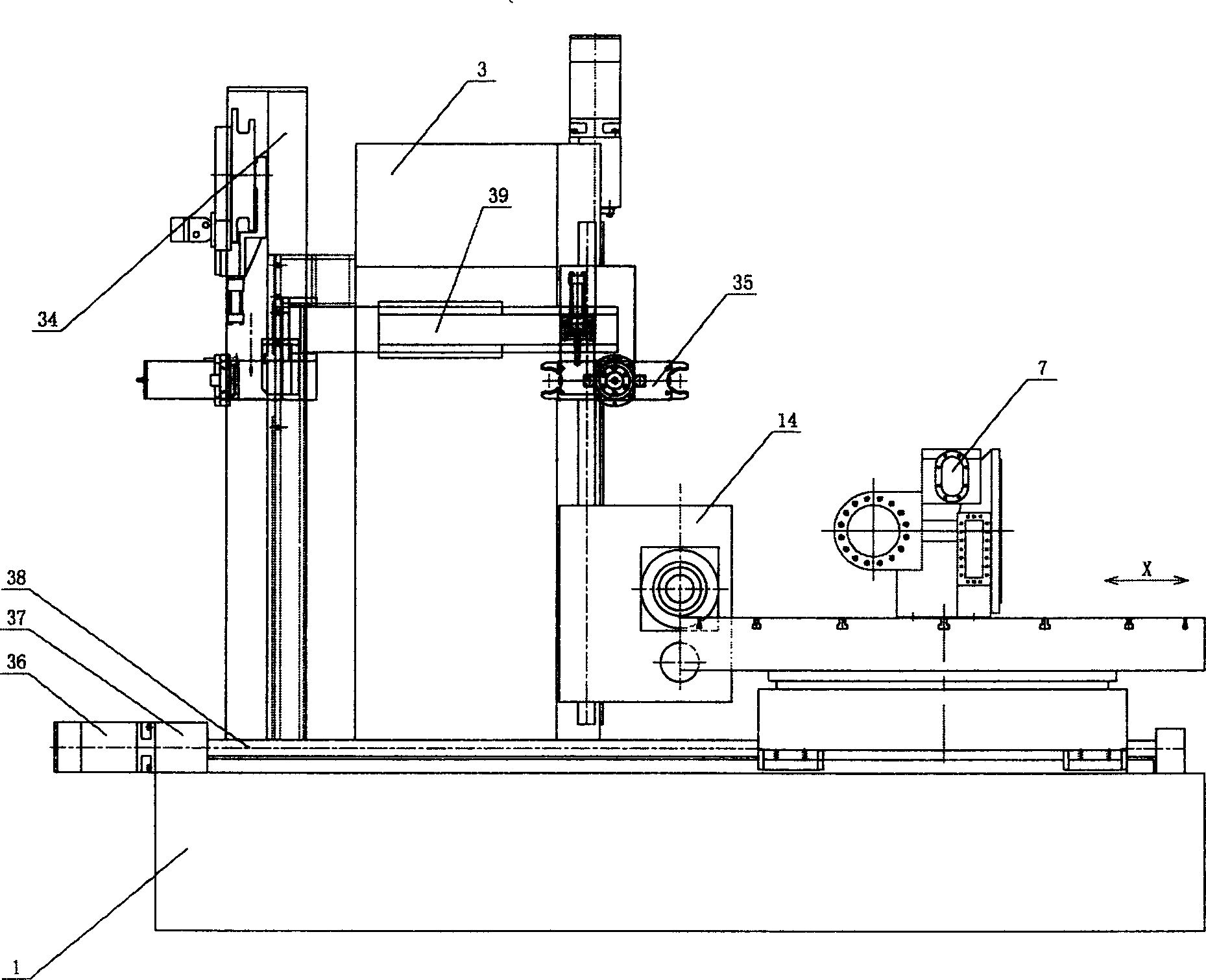

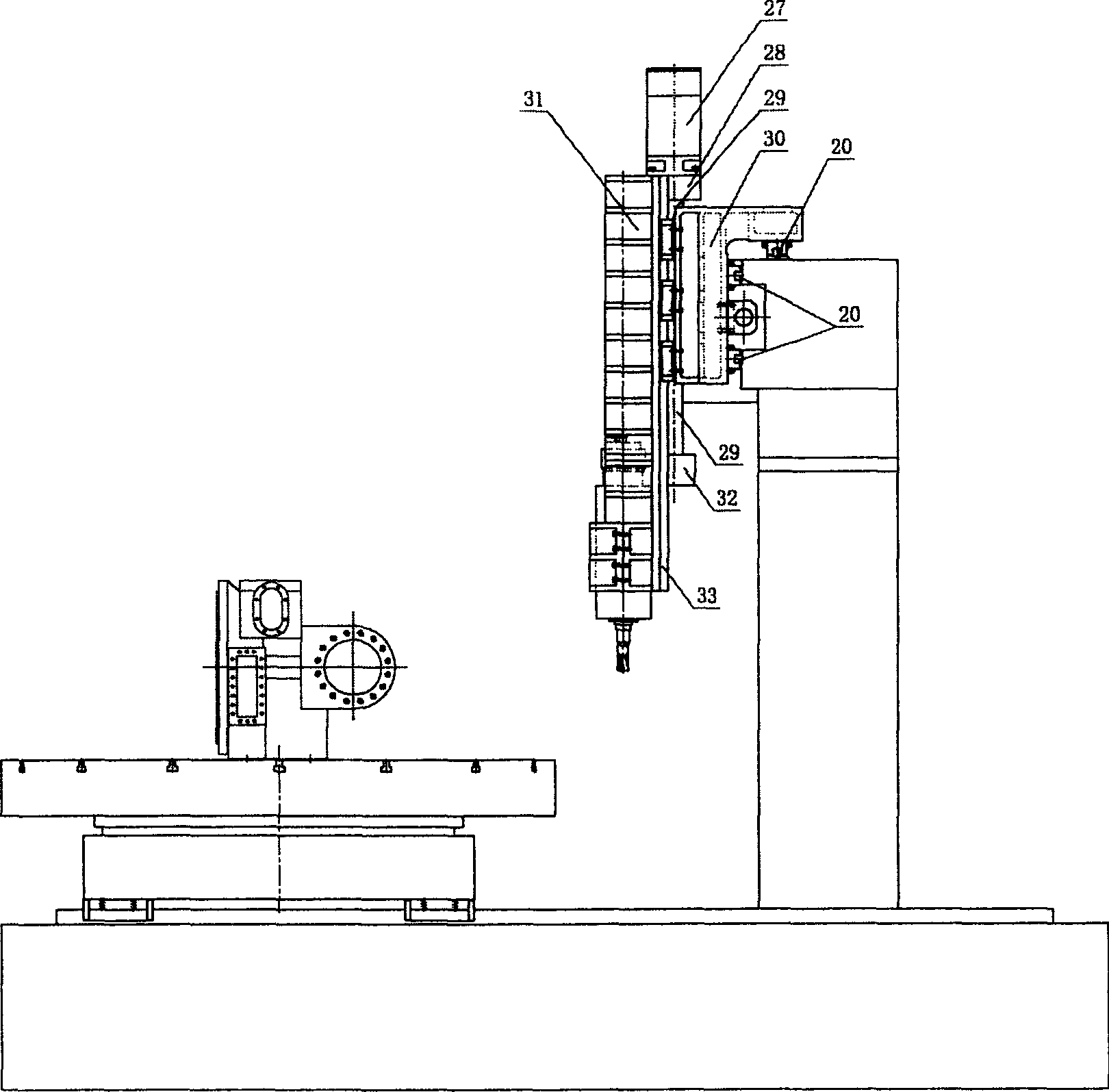

[0010] As shown in the figure, the structural scheme and working process of the present invention are further described in conjunction with examples.

[0011] A vertical and horizontal high-speed boring and milling automatic machining center, which includes a frame bed 1, a high-speed milling electric spindle component, a horizontal sliding table component, an indexing table 6, a chain tool magazine 34, a disc tool magazine 24, Tool changing manipulator 35, boring and milling spindle box body parts and electrical control system. The frame bed is formed by connecting the left and right columns 2 and 3 with the bed base 1 and the upper beam 21 through connecting bolts to form a frame bed. The hydraulic indexing table 6 is set on the horizontal motion slide table 5, the horizontal motion slide table 5 is set on the bed base 1 through the X-direction rolling guide rail 4, and the X-direction servo motor 36 is fixed on the rear end of the bed base 1, It is connected with the X-dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com