High performance grouting addition for concrete with post-tensioning binding prestressing force

A bonded prestressing and admixture technology, which is applied in the field of special admixtures for post-tensioned bonded prestressed concrete structures, can solve problems such as the inability to guarantee the quality of grouting, and achieve improved volume stability, strong temperature adaptability, and fluidity lossless effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Component 1: 4.8%; Component 2: 0.01 5% Component 3: 61%;

[0027] Component 4: 17% Component 5: 17%; Component 6: 0.065%;

[0028] Component 7: 0.08%

[0029] The present invention is obtained by mixing the components together in the above weight ratio.

[0030] Adopt the performance of the grouting material that forms after the present invention mixed with cement that is made by above-mentioned formula is:

[0031] The physical properties of grouting materials are shown in Table 2:

[0032] Preface

[0033] Note: The ratio of water to cement used (namely water / (cement+JM-HF)): "Julong" 42.5P·O is 0.35, others are 0.37. JM-HF is that the dosage of the present invention is internal doping. The physical properties of grouting materials are shown in Table 3:

[0034] Preface

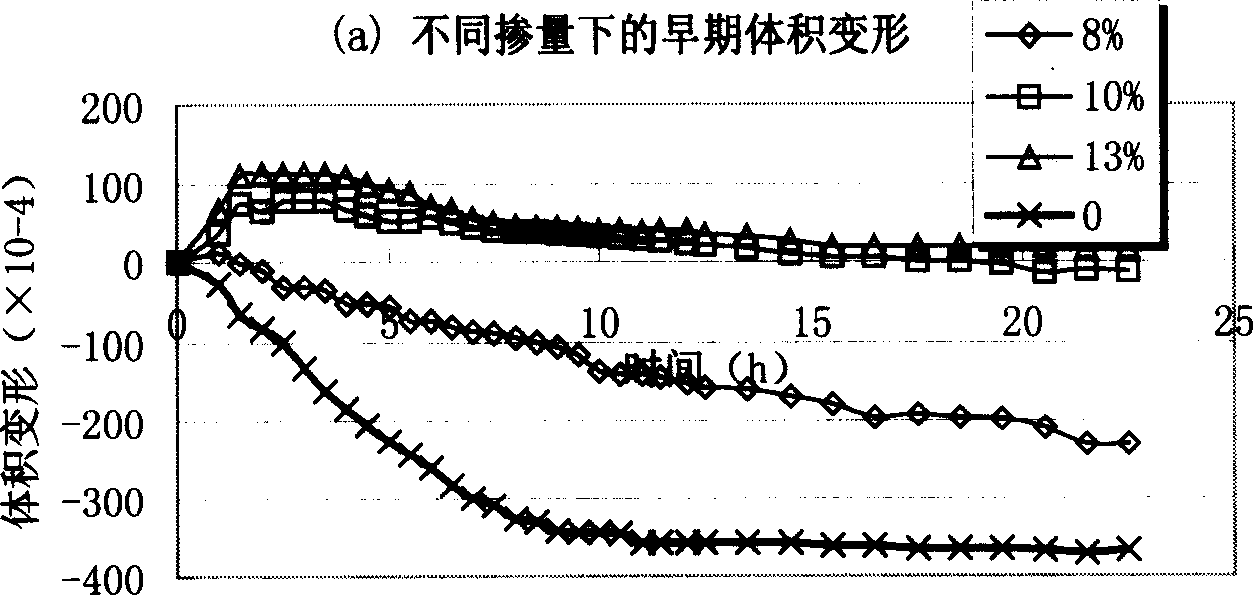

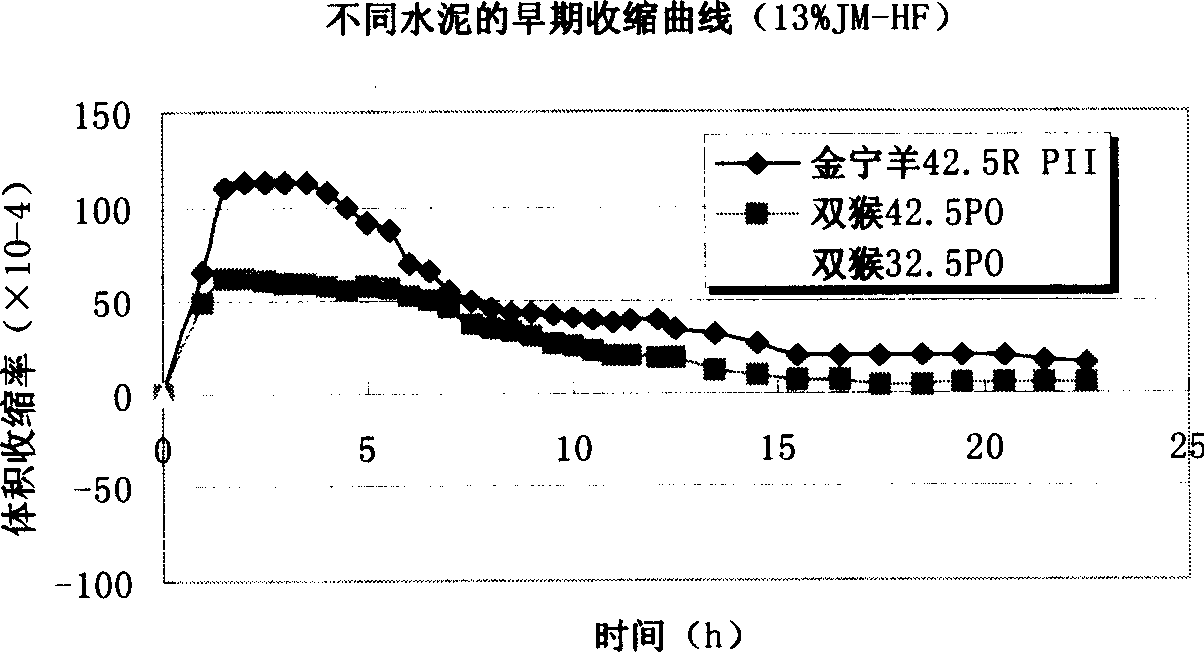

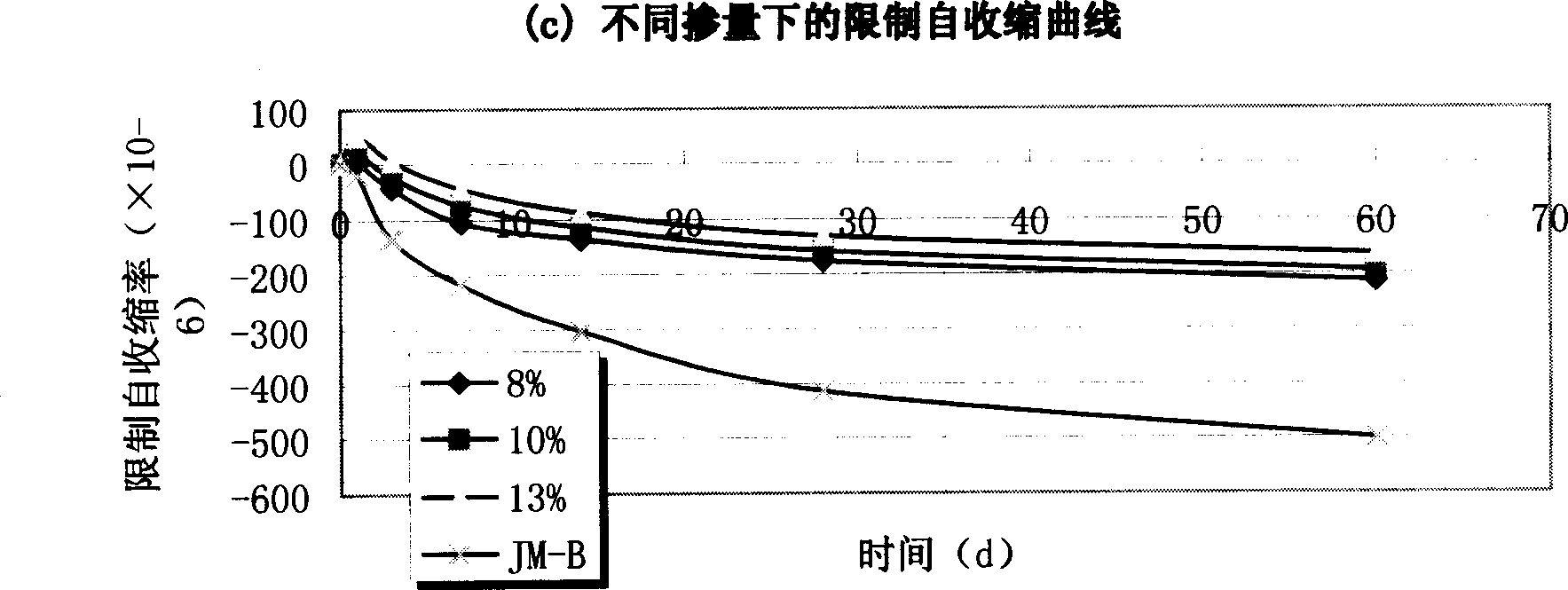

[0035] The early volume deformation of the grouting material formed by the same cement at different dosages (that is, adding different amounts of the present invention in th...

Embodiment 2

[0037] Component 1: 7.95%; Component 2: 0.005%

[0038] Component 3: 52%; Component 4: 19.5%

[0039] Component 5: 19.5%; Component 6: 0.05%;

[0040] Component 7: 0.05%

[0041] The present invention is obtained by mixing the components together in the above weight ratio.

[0042] The performance after adopting the present invention that is made by above-mentioned formula to mix cement (replacing 13% of cement consumption) is:

Embodiment 3

[0045] Component 1: 7.8%; Component 2: 0.02%

[0046] Component 3: 68%; Component 4: 12.59%

[0047] Component 5: 12.59%; Component 6: 0.1%;

[0048] Component 7: 0.05%

[0049]The present invention is obtained by mixing the components together in the above weight ratio.

[0050] The performance after adopting the present invention that is made by above-mentioned formula to mix cement (replacing 13% of cement consumption) is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com