Method and device for dehydration of glycol by extending coking period of tower-drier reboiler

A dehydration device and drying tower technology, applied in hydrolysis preparation, separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problem that the reboiler coking period cannot be alleviated, increase the flow rate of high-pressure steam, and accelerate coking on the inner tube wall of the tubes and other problems, to achieve the effect of avoiding the parking loss of coke cleaning, reducing sewage discharge, and saving the cost of coke cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The feed temperature of the ethylene glycol solution into the drying tower is 95°C. The drying tower and the drying tower reboiler have been in normal operation for about 6 months, and they need to be stopped to clean the coke. During this period, the drying tower evaporates or the drying efficiency decreases. By increasing the reboiler The high-pressure steam input to the dryer maintains the normal operation of the drying tower until it is shut down due to coking in the reboiler of the drying tower. In fact, the ethylene glycol solution at 95°C can be directly obtained from the bottom liquid of the vacuum tower of the evaporation system through temperature control, that is to say, there is no need to add an additional ethylene glycol solution preheating device.

Embodiment 2

[0031] The feed temperature of the ethylene glycol solution into the drying tower is 130°C. The drying tower and the reboiler of the drying tower have been in normal operation for more than 6 months. The reboiler of the drying tower has not been coked. The reduction, however, is cumbersome to preheat the glycol solution. It can be seen that the setting of this process parameter is conducive to solving the problem of coking in the reboiler of the drying tower.

Embodiment 3

[0033] Raise the feed temperature, change from cold feed to bubble point feed, that is, heat the 95°C tower kettle liquid through the preheater to 115°C before entering the drying tower. At this time, the feed temperature is basically the same as the feed plate temperature. This reduces the heat load on the reboiler and eases the reboiler coking cycle.

[0034] We officially installed it in 2000. The feed temperature was heated from 95°C to 115°C with medium-pressure steam at 300kg / h. It is basically the same, but the machine cleaning fee saved in two years is considerable, the avoided waste water is amazing, and the benefits to the enterprise are huge.

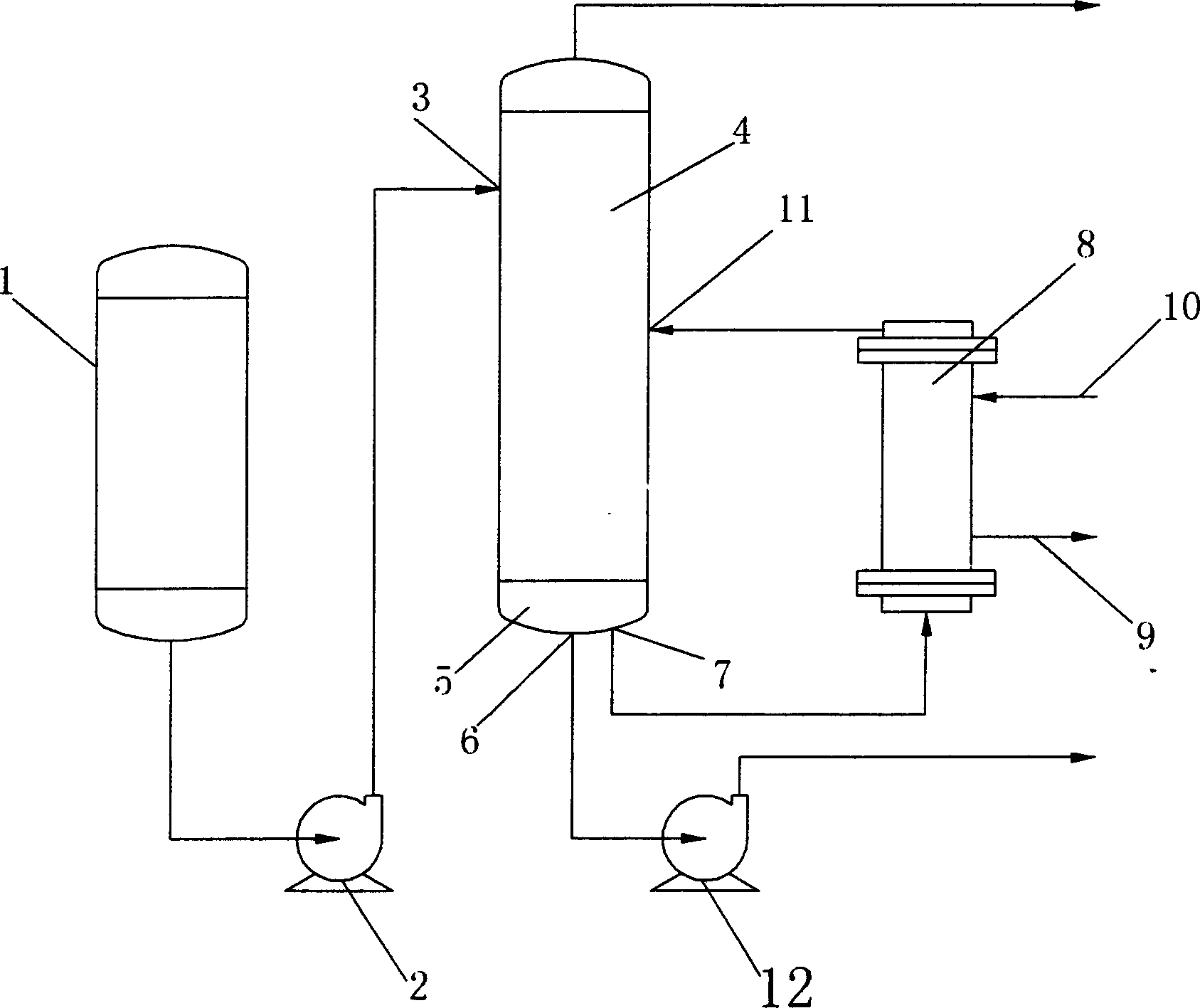

[0035] The ethylene glycol dehydration device for prolonging the coking cycle of the drying tower reboiler of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0036] Such as figure 2The shown ethylene glycol dehydration process device of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com