Light emitting unit structure with different colour on two faces

A technology of light-emitting unit and light-emitting element, which is applied in the direction of electroluminescence light source, light source, electric light source, etc., and can solve the problems of reducing light use efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Relevant detailed description and technical contents of the present invention are as follows with regard to coordinating accompanying drawings now:

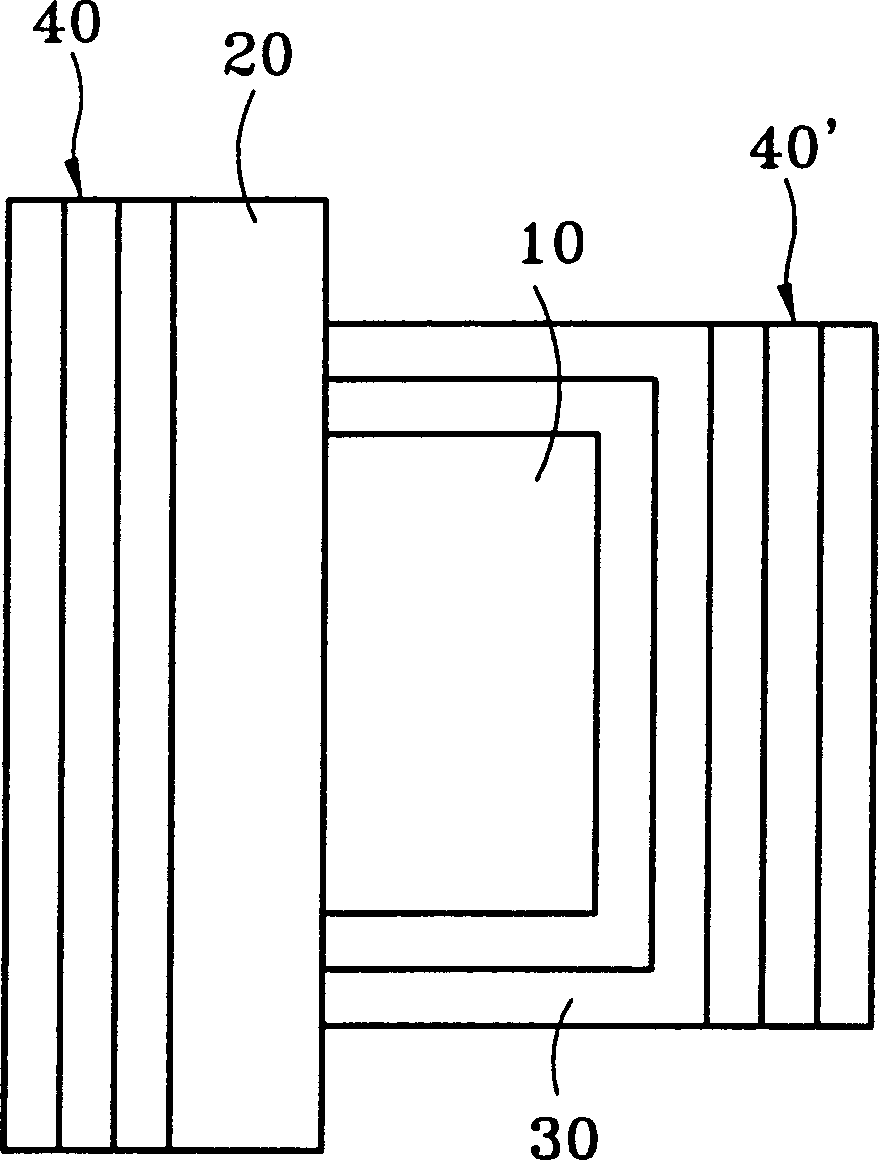

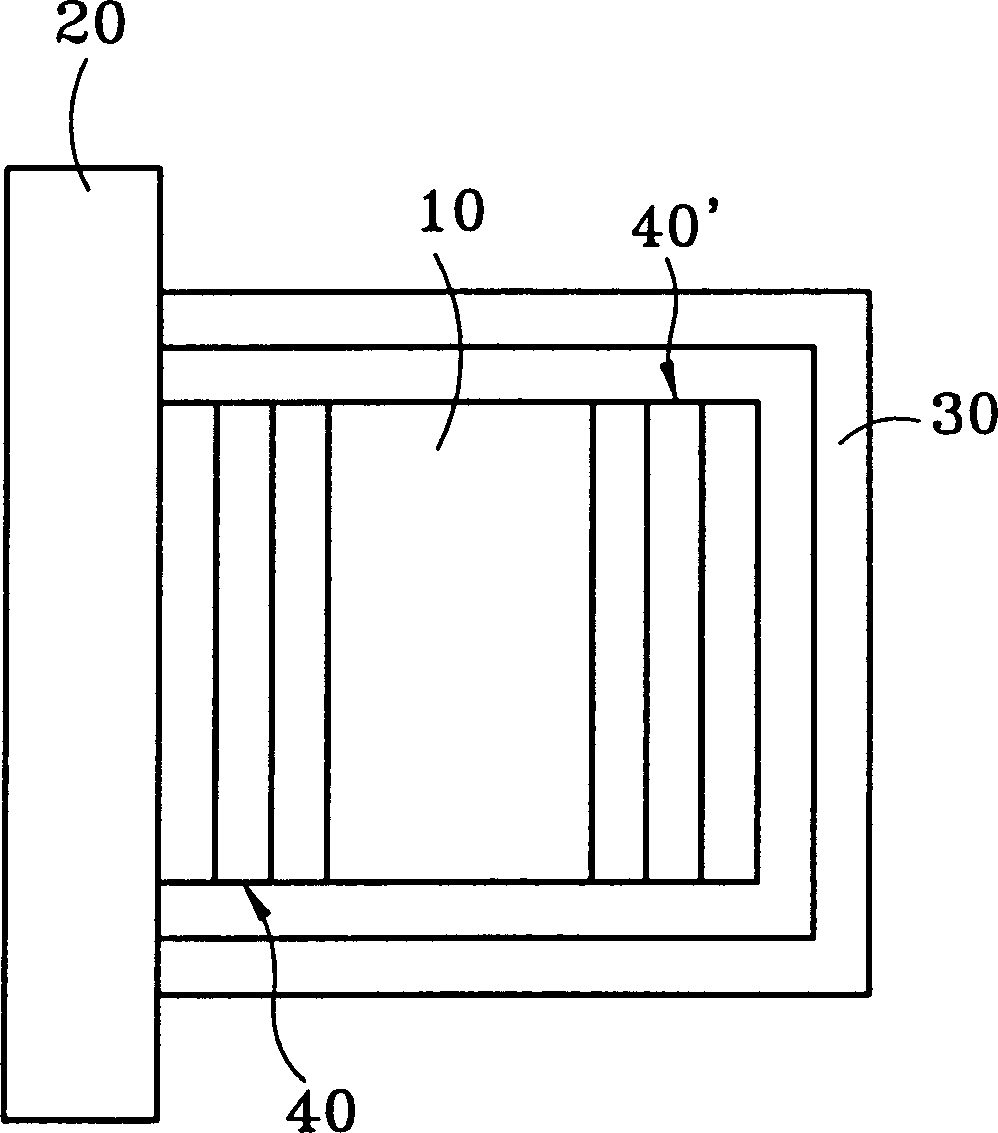

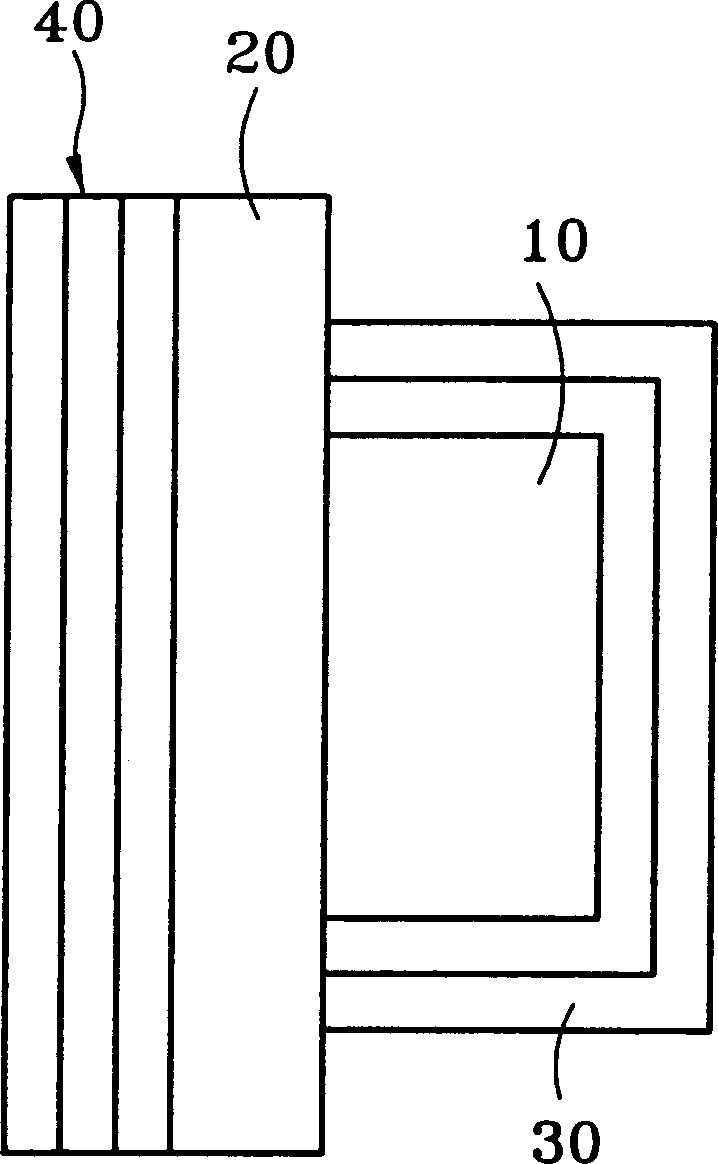

[0014] see figure 1 As shown, it is a schematic diagram of the first state of the light-emitting unit structure of the present invention. As shown in the figure: the present invention utilizes an optical inorganic thin film 40, 40' structure, and the optical inorganic thin film 40, 40' combines self-luminous transparent light-emitting The element 10 can realize the purpose of emitting light of different colors on both sides. The way of making is as follows, coating an optical inorganic thin film 40 on the outside of the transparent substrate 20, and coating an optical inorganic thin film 40' on the inside or outside of the transparent package cover to have high-pass filter (High pass filter), low-frequency filter (Low pass filter) or band pass filter (Band pass filter), using various optical inorganic thin films 40, 40' t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com