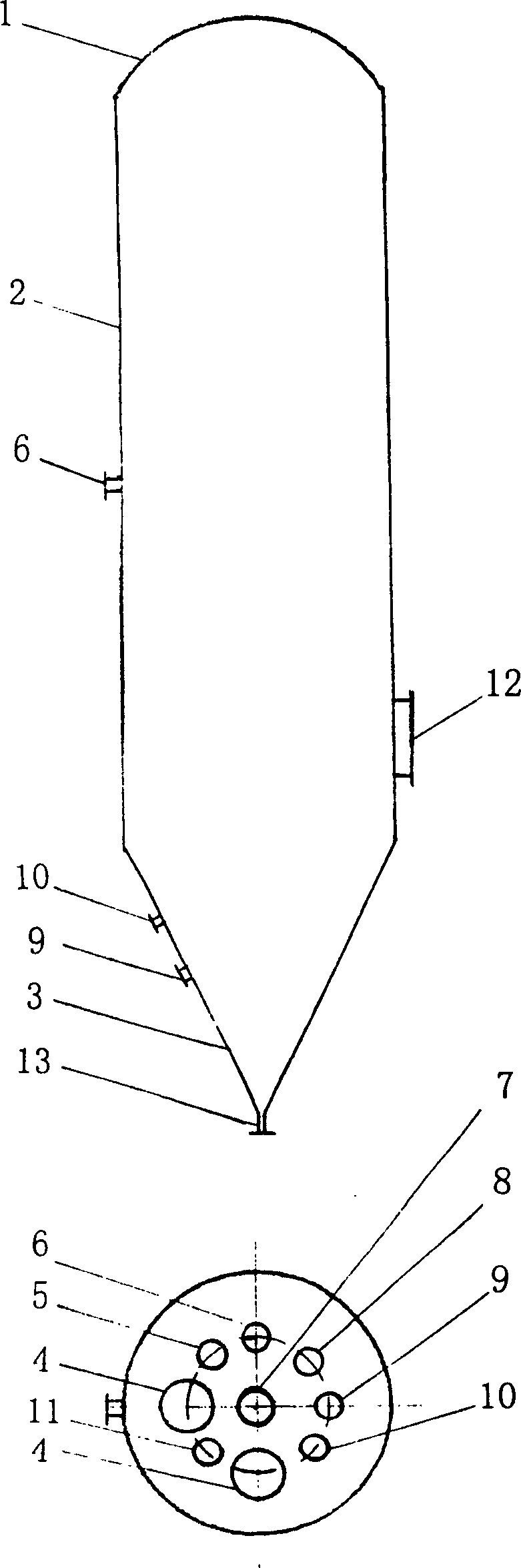

Process and apparatus for continuous manufacturing burnt sugar colouring matter

A technology of caramel pigment and equipment, which is applied in the field of continuous production of caramel pigment technology and equipment, to achieve the effects of high product color rate, automatic control of the whole process, and high red index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Take the production of ammonia (ammonium) caramel as an example:

[0029] 1) Start the agitator on the batching tank, add 3 tons of syrup with a DE value of 90, a concentration of 30Be' (55% on a dry basis) and a temperature of 60°C into the batching tank, and feed it to the batching tank through the liquid ammonia metering tank Slowly add liquefied ammonia, the liquefied ammonia should be added at the bottom of the batching tank, the amount added is about 3% of the dry basis of the syrup, that is 50Kg, the whole adding process is 40 minutes, the pH value of the syrup rises from the initial 3.6 to 10.10, the temperature From 60°C to 67°C, add 300M1 defoamer.

[0030] 2) Preheat the material to 90°C through the heat exchanger, then raise the temperature of the material to 138°C through the steam injector, and then the material enters the reactor, and controls the discharge valve on the reactor through the sight glass on the reactor, so that The pressure on the reactor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com