Non-evaporation type getter, display unit and production method for them

A non-evaporative, getter technology, applied in the manufacture of chemical instruments and methods, image/graphic display tubes, ships or lead-in wires, etc., can solve problems such as difficult to set non-evaporative getters, and achieve shrinkage stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

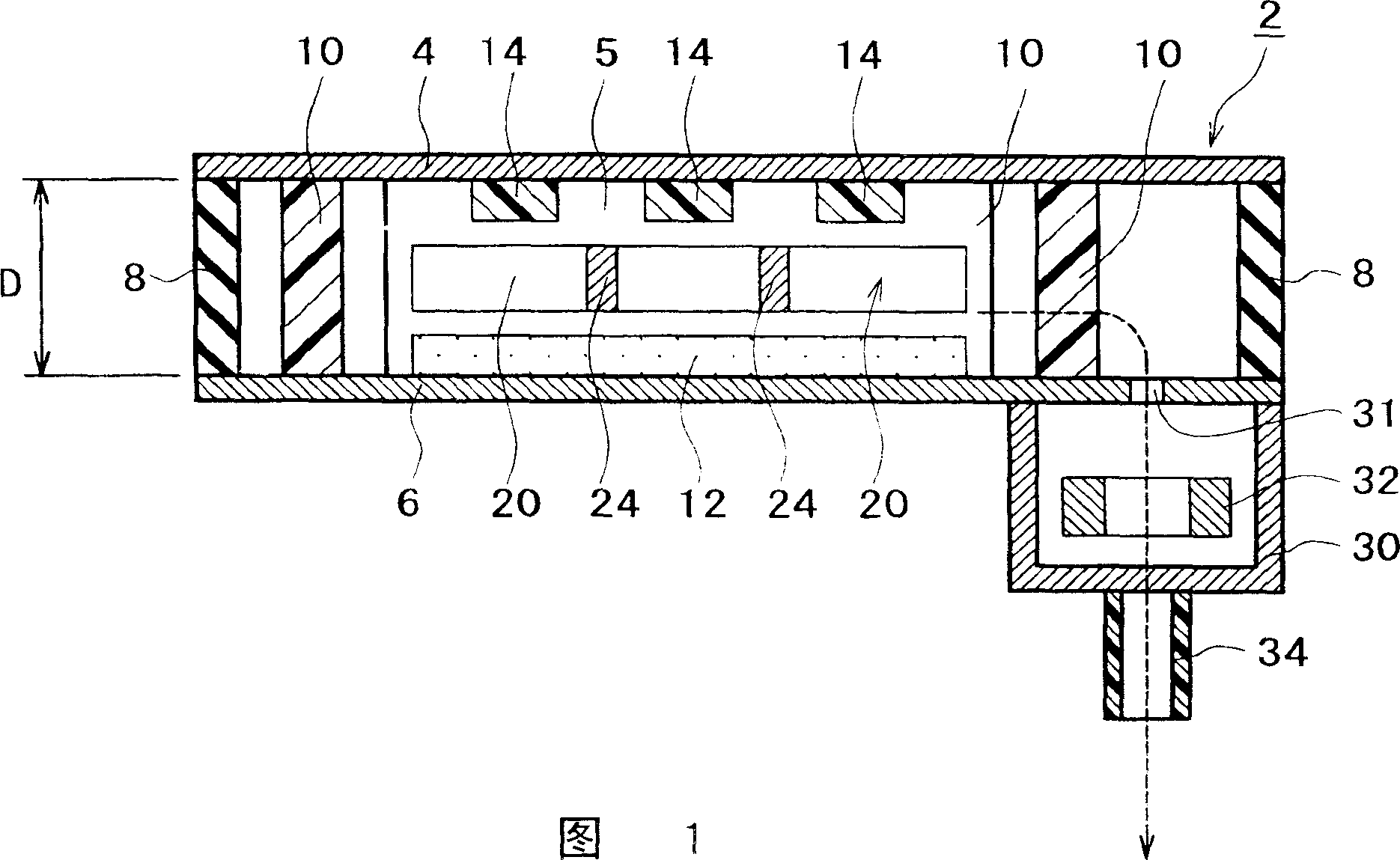

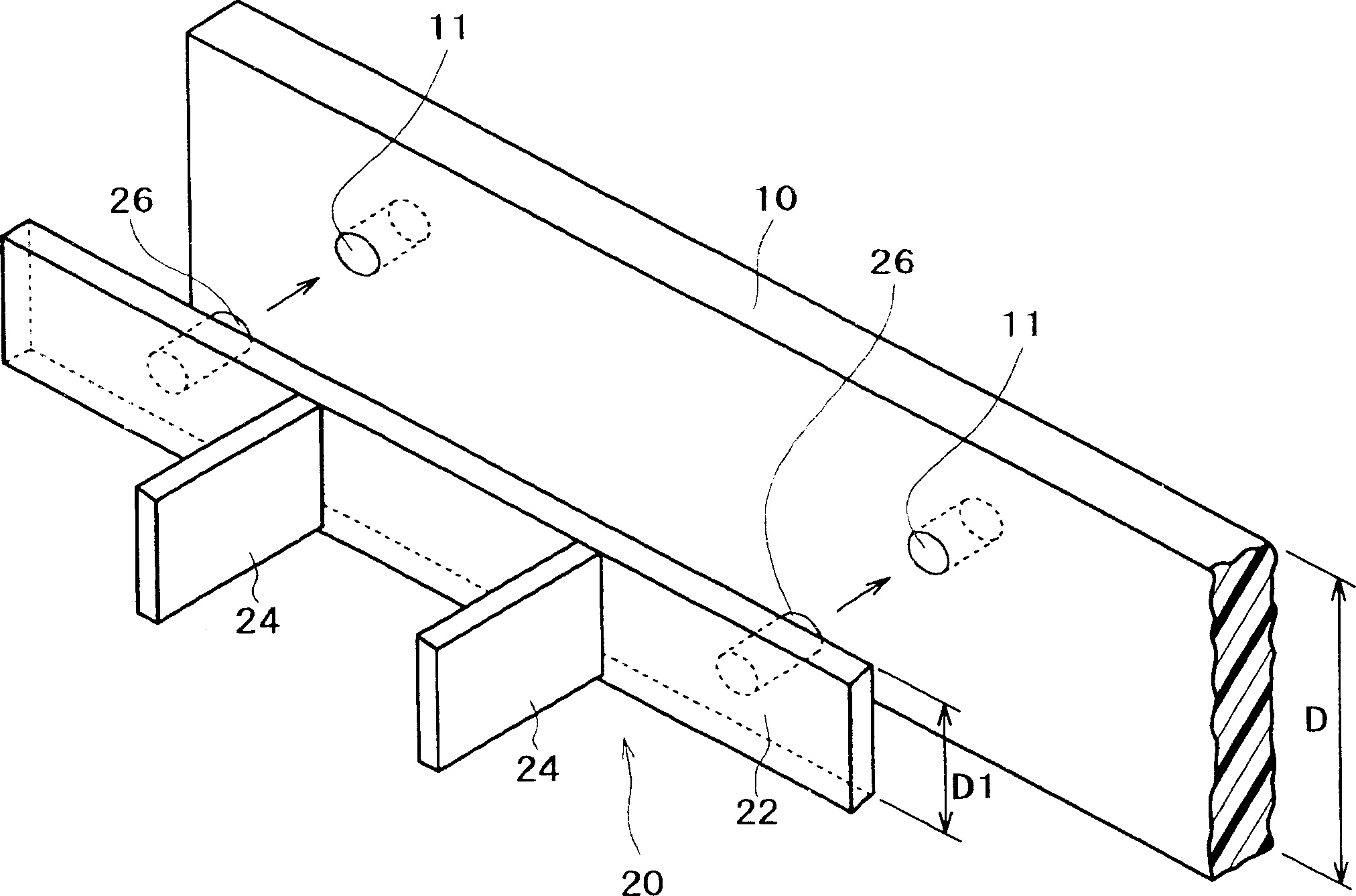

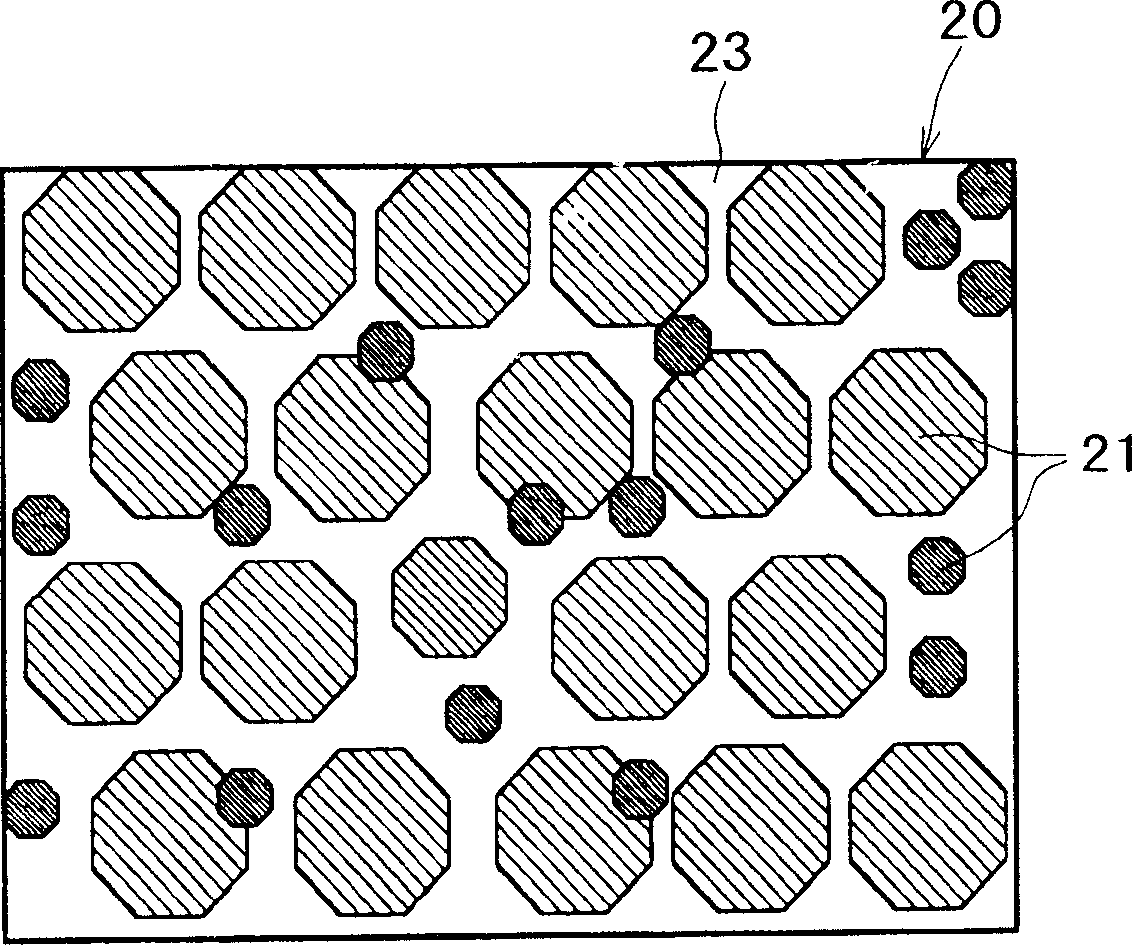

[0063] The invention will now be described on the basis of an embodiment shown in the drawings.

[0064] 1 is a general cross-sectional view of a flat panel display device according to an embodiment of the present invention; figure 2 is a perspective view showing the relationship between the separator and the non-evaporable getter shown in FIG. 1; Figure 3A is an enlarged conceptual diagram of a main part of a non-evaporable getter according to an embodiment of the present invention, Figure 3B is an enlarged conceptual diagram of a non-evaporable getter according to another embodiment of the present invention; Figure 4A to Figure 4D is a perspective view showing the shape of a non-evaporable getter according to another embodiment of the present invention; Figure 5A is a graph showing the gettering capacity of the non-evaporable getter according to one embodiment of the present invention and the gettering capacity of the conventional non-evaporable getter, Figure 5B is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com