Infrared heat wave detecting system with THZ wave as light source

A detection system, infrared heat wave technology, used in measurement devices, material defect testing, material analysis by optical means, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

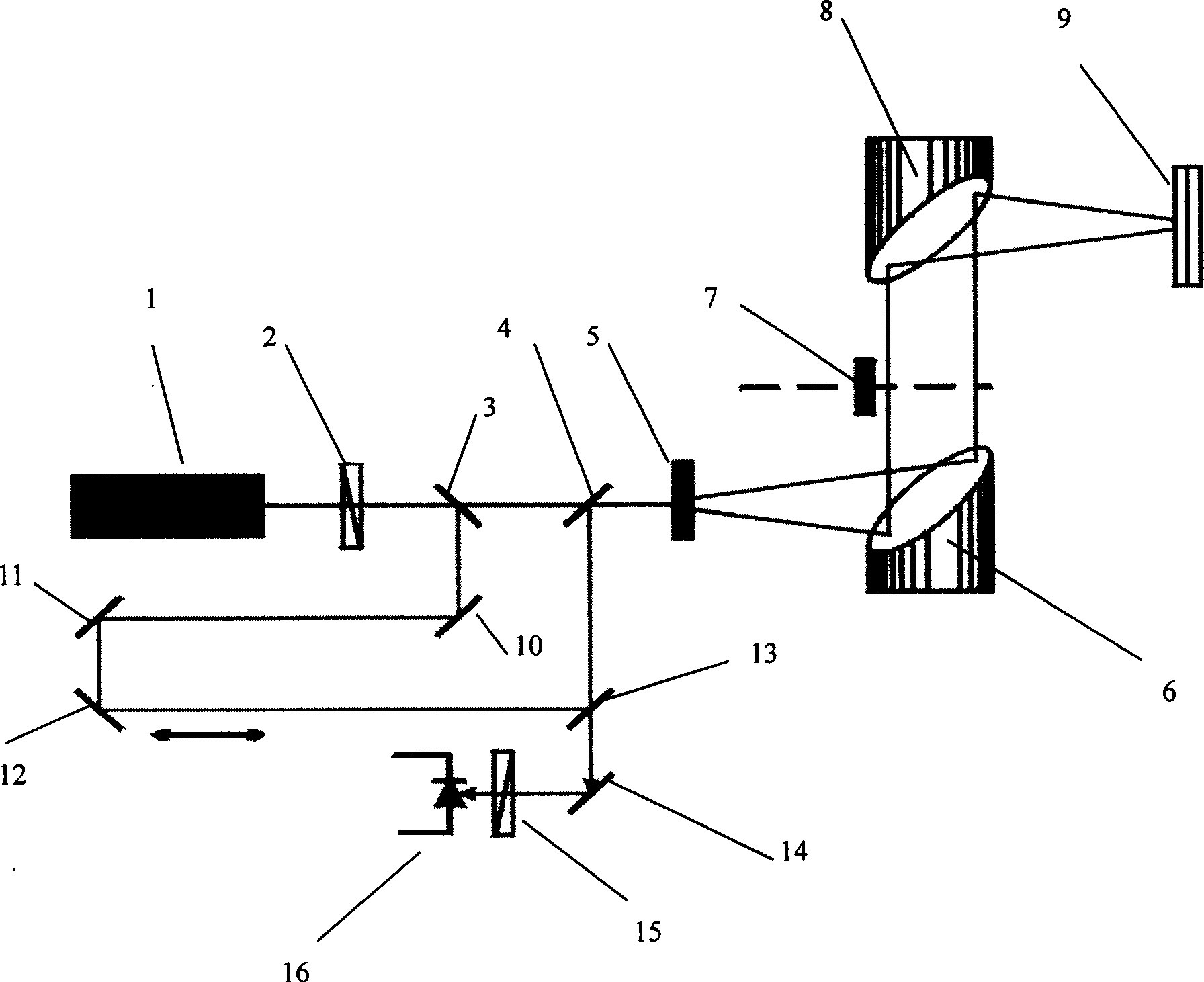

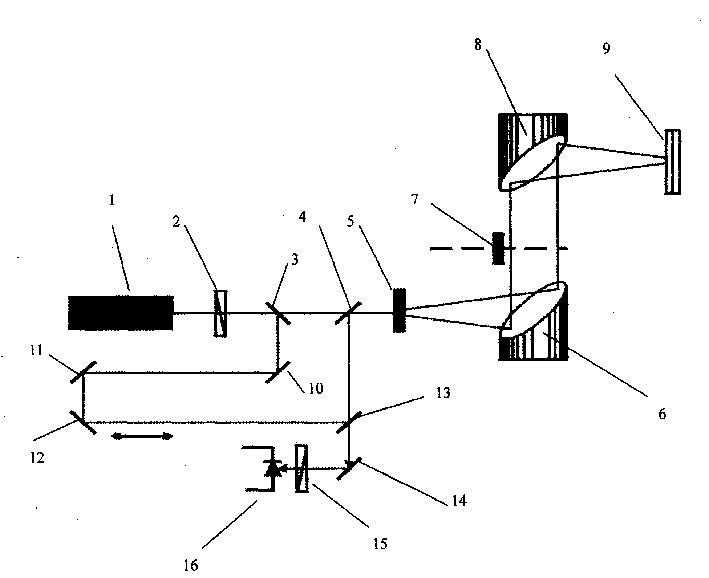

[0022] refer to figure 1 , this infrared thermal wave detection system integrates the THz wave generation system, the THz wave heating system and the THz wave imaging system. A beam of pulsed light source is emitted by the laser 1 with a wavelength of 800nm and a pulse width of 30fs, which passes through the polarizer 2. Divide the light beam into two beams through the beam splitter 3, and one beam of pump light passes through the beam splitter 3 and the beam splitter 4 and irradiates the crystal 5, and generates a pulsed THz wave, which passes through the paraboloid Mirror 6, chopper 7, and parabolic mirror 8 irradiate the sample 9, and then the THz wave reflected on the sample 9 returns to the crystal 5 through the parabolic mirror 8, chopper 7, and parabolic mirror 6 according to the original path. And through the crystal 5, the crystal 5 is a ZnTe electro-optic crystal. Another beam of probe light reflected by the beam splitter 3 passes through a delayed optical path co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com