Mechanical double lead-screw drive pair

A twin-screw, mechanical technology, applied in the direction of mechanical equipment, transmission devices, belts/chains/gears, etc., can solve the problems of low transmission efficiency, complex processing technology, and no self-locking function of worm gear transmission mechanisms, and achieve light weight , Simplify the bearing structure and improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

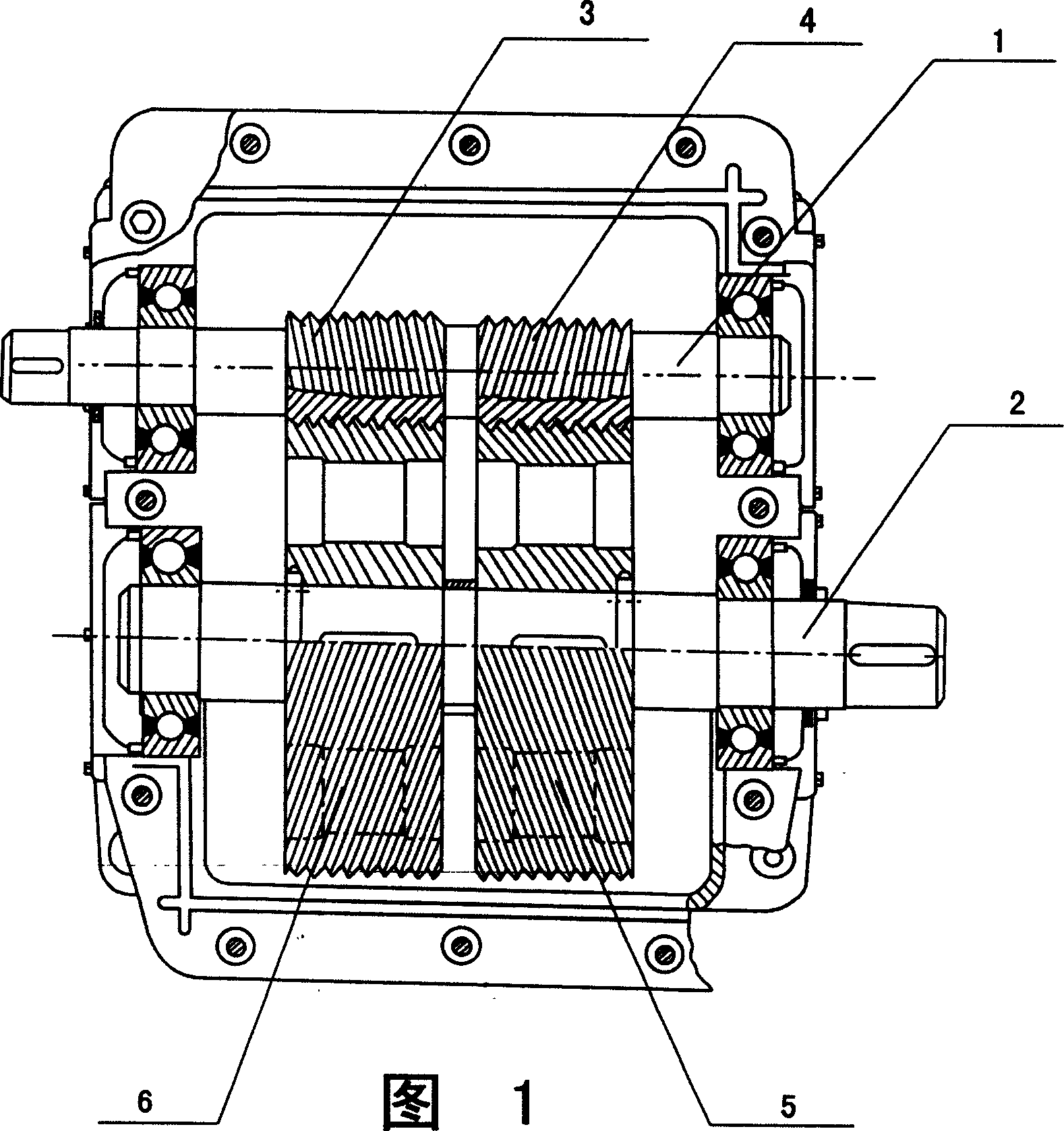

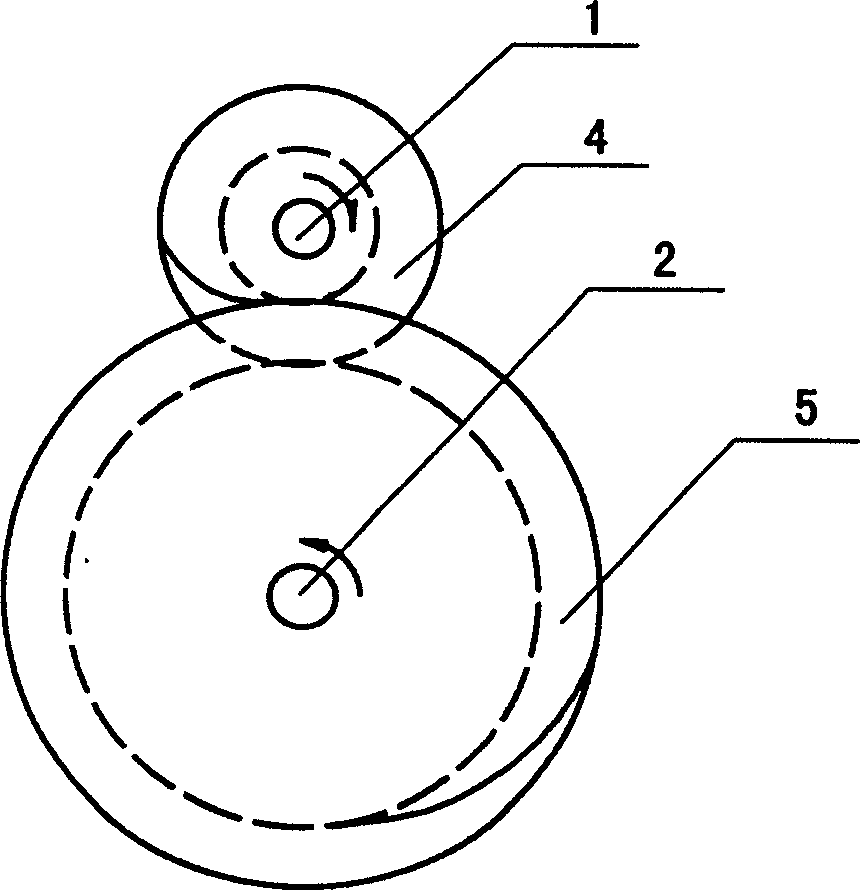

[0023] As shown in Figure 1, the main structure of the mechanical twin-screw transmission is a box, on which an input shaft and an output shaft are installed in turn, and bearings are arranged at both ends of the shaft and installed on the bearing seat of the box. The input shaft 1 is provided with two first-stage active screws 3 and 4 with coaxial cores, 3 is a right-handed screw, 4 is a left-handed screw, and the output shaft 2 is equipped with driven screws 5 and 6, which are left-handed driven screws. 6 meshes with the right-handed driving screw 3, and the right-handed driven screw 5 meshes with the left-handed driving screw 4. The transmission ratio of the main and driven screws can be designed as deceleration, constant speed or speed increase. The transmission screws assembled on the same transmission shaft are designed as left and right spiral screws that appear in pairs. The transmission screws can also be designed as Single-start screw or multi-start screw. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com