Parallel mechanism with six degrees of freedom used for virtual shaft numerical control machine tool and parallel robot

A technology of numerical control machine tools and virtual axes, applied in the direction of adopting mechanical devices, instruments, manipulators, etc., can solve the problems of high-precision ball joints, complex structures, complex manufacturing and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technology of the present invention will be further described below by means of accompanying drawings and examples.

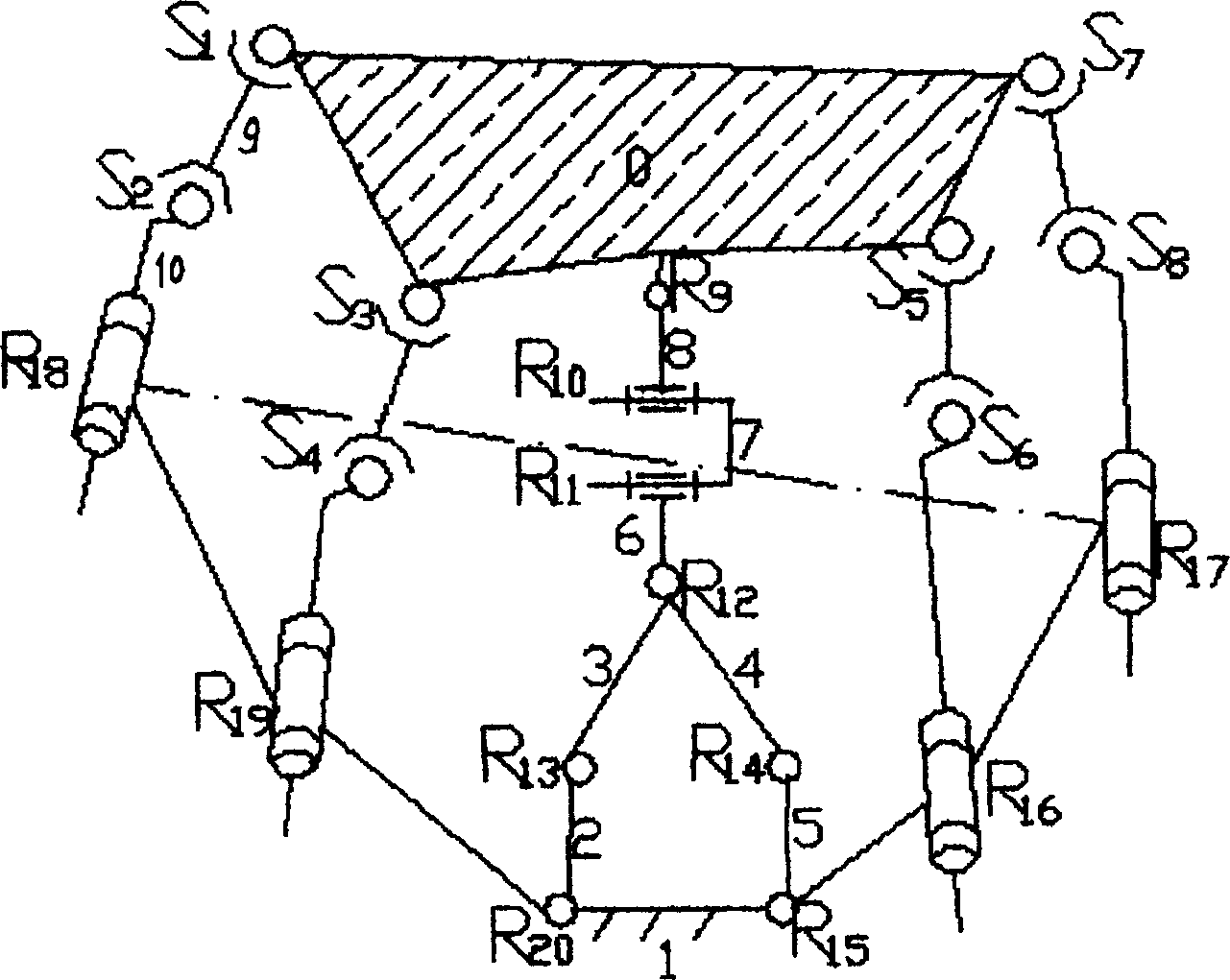

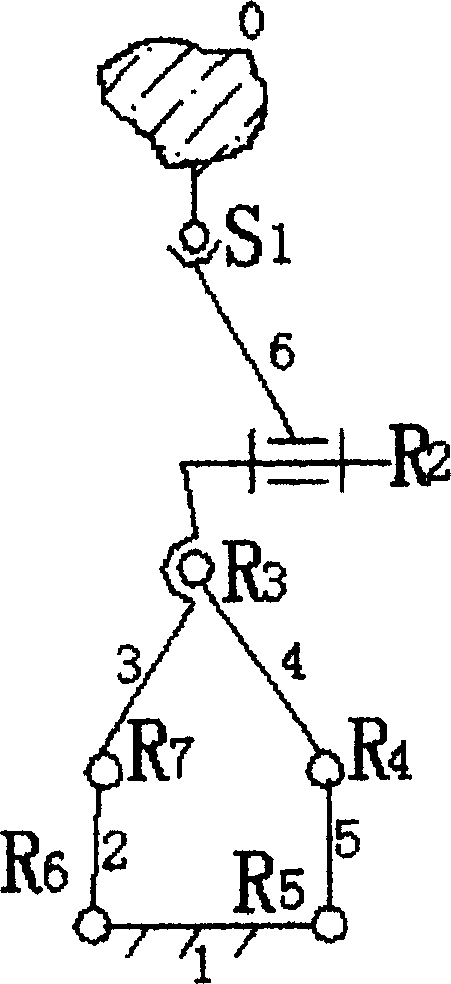

[0024] attached figure 1 The shown parallel mechanism can be an embodiment of the present invention, and it consists of an upper moving platform 0, a lower static platform 1, a mixed chain leg connecting the upper and lower platforms, and four simple open chain legs with the same structure. The hybrid chain leg is composed of a plane closed-circuit structure and an open chain structure. The plane closed-circuit structure consists of five rods (1, 2, 3, 4, 5) passing through five rotating pairs (R 20 , R 13 , R 12 , R 14 , R 15 ) connection, its components 2 and 5 are respectively connected with the static platform 1 with a revolving pair (R 20 , R 15 ) mechanical connection; the members 6, 7, 8 of the open chain structure are respectively passed through two rotating pairs whose axes are parallel to each other (R 11 , R 10 ), and the member 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com