Effect increased urea by adding potassium and its preparation method

A technology of urea and potassium sulfate, applied in the directions of fertilizer mixture, fertilizer form, fertilization device, etc., can solve the problem of single urea nutrient, and achieve the effect of simple production method, long fertilizer effect, and lodging prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 (low metering)

[0020] It is composed of urea and potassium sulfate, 1 kg is 1 part, 44 kg of urea, 8 kg of potassium sulfate, 48 kg of fluorspar powder; the content of nitrogen is 20%, and the content of potassium is 4%.

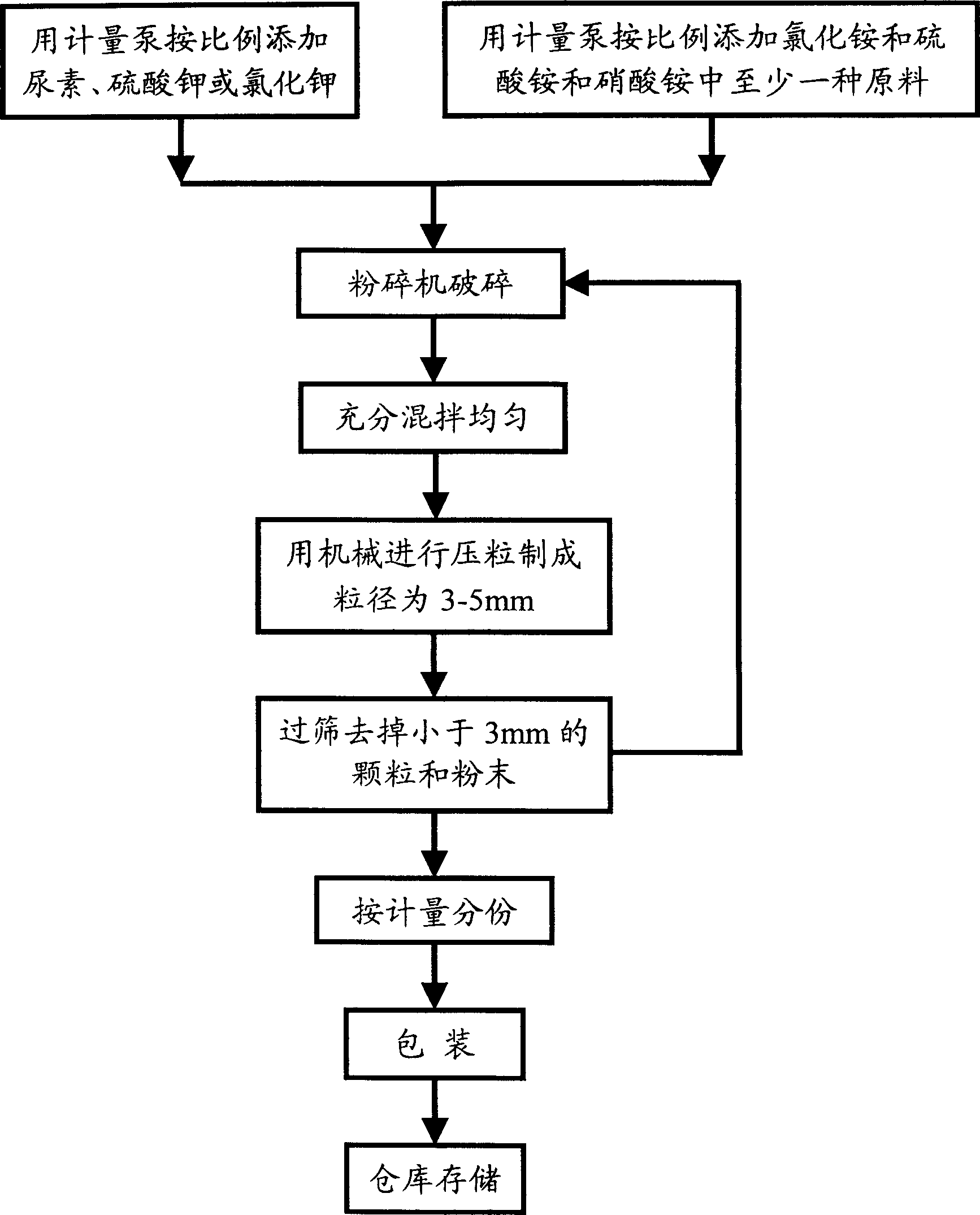

[0021] When making, use a metering pump to add and mix urea and potassium sulfate in proportion, pulverize them through a pulverizer, put them into a mixer and stir them fully, and then press them mechanically to make granules with a particle size of 3-5mm, and remove them by sieving. Particles and powders smaller than 3mm are measured and packaged, and stored in warehouses; particles and powders with particle sizes smaller than 3mm are sieved and crushed, fully stirred, and granulated by machinery, such as figure 1 shown.

Embodiment 2

[0022] Example 2 (medium dose)

[0023] It is composed of urea and potassium sulfate, with 1kg as one part, 61kg of urea, 24kg of potassium sulfate, and 15kg of fluorspar; the content of nitrogen is 28%, and the content of potassium is 12%.

[0024] During production, use a metering pump to add and mix urea, potassium sulfate and fluorspar in proportion, pulverize through a pulverizer, put them into a mixer and stir them fully, and then press them mechanically to make particles with a particle size of 3-5mm, and pass through a sieve Particles and powders with a particle size of less than 3mm are separated and removed, measured and packaged, and stored in a warehouse; particles and powders with a particle size of less than 3mm are sieved and then pulverized and fully stirred, and then granulated by machinery, such as figure 1 shown.

Embodiment 3

[0025] Example 3 (high metering)

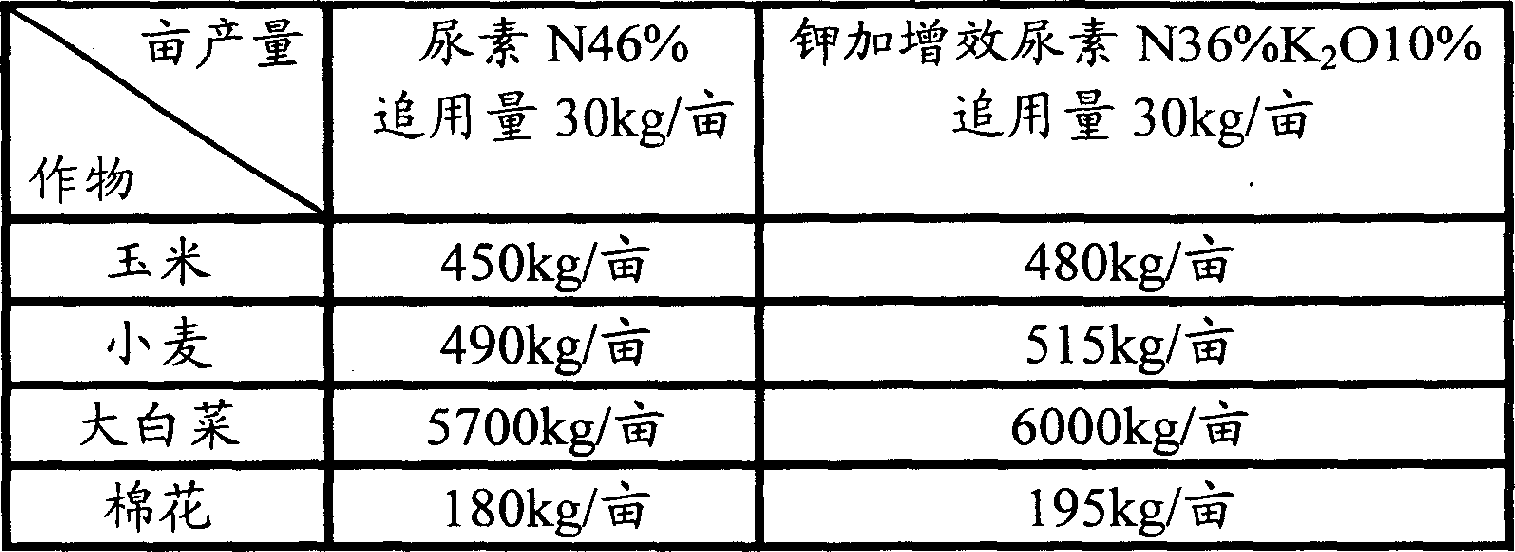

[0026] It is composed of urea and potassium sulfate, with 1 kg as one part, 78 kg of urea, 20 kg of potassium sulfate, and 2 kg of fluorspar powder; the content of nitrogen is 36%, and the content of potassium is 10%.

[0027] When making, use a metering pump to add and mix urea, potassium sulfate and fluorspar powder in proportion, pulverize through a pulverizer, put them into a mixer and stir them fully, and then press them mechanically to make granules with a particle size of 3-5mm, and pass through sieving Remove particles and powders with a particle size of less than 3mm, measure and pack them, and store them in a warehouse; sieve the particles and powders with a particle size of less than 3mm, crush them and mix them thoroughly, and press them mechanically, such as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com