Indirect extrusion casting process

A squeeze casting and indirect technology, which is applied in the field of indirect squeeze casting, can solve the problems of large melt temperature drop, difficulty in pouring alloy melt, and high energy consumption of hydraulic system, so as to reduce the melt pouring temperature and facilitate automatic production. , The effect of reducing the energy consumption of smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

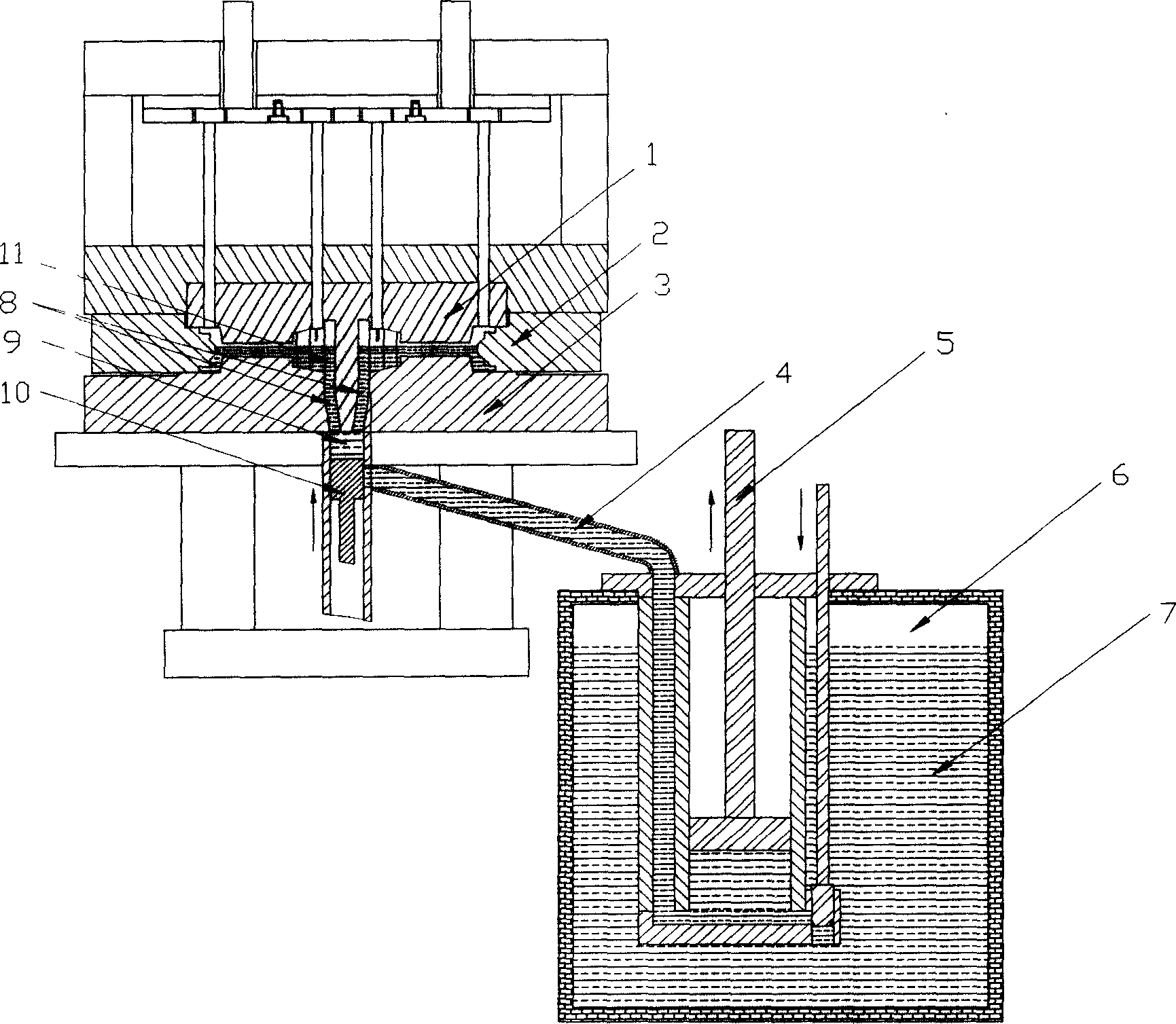

[0014] Below in conjunction with the accompanying drawings and the embodiments are further described:

[0015] The embodiment takes the indirect squeeze casting of magnesium alloy wheels as an example, and its technological process is:

[0016] 1. Low-pressure filling and extrusion solidification: The magnesium alloy melt [7] in the alloy molten pool [6] is poured and filled through the pouring pipe [4] under the action of the piston pouring device [5], and the filling is about to be completed. When the extrusion head [10] goes up to close the pouring pipeline [4] and starts to pressurize and feed the magnesium alloy melt in the casting mold, at the same time, the piston pouring device [5] goes up and returns, and the magnesium alloy melt in the pouring pipeline [4] The body flows back into the alloy molten pool [6], and when the casting mold is full, the pressure of the extrusion head [10] is rapidly increased to above 1.0 MPa, and the pressure is maintained until the casting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com