Belt converyer for mounting componenet

An installation machine and belt conveying technology, applied in electrical components, electrical components, conveyor objects, etc., can solve the problems of reduced workability, increased conveyor volume, defective products, etc., to prevent overturning and falling off, and increase the number of installations. , the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

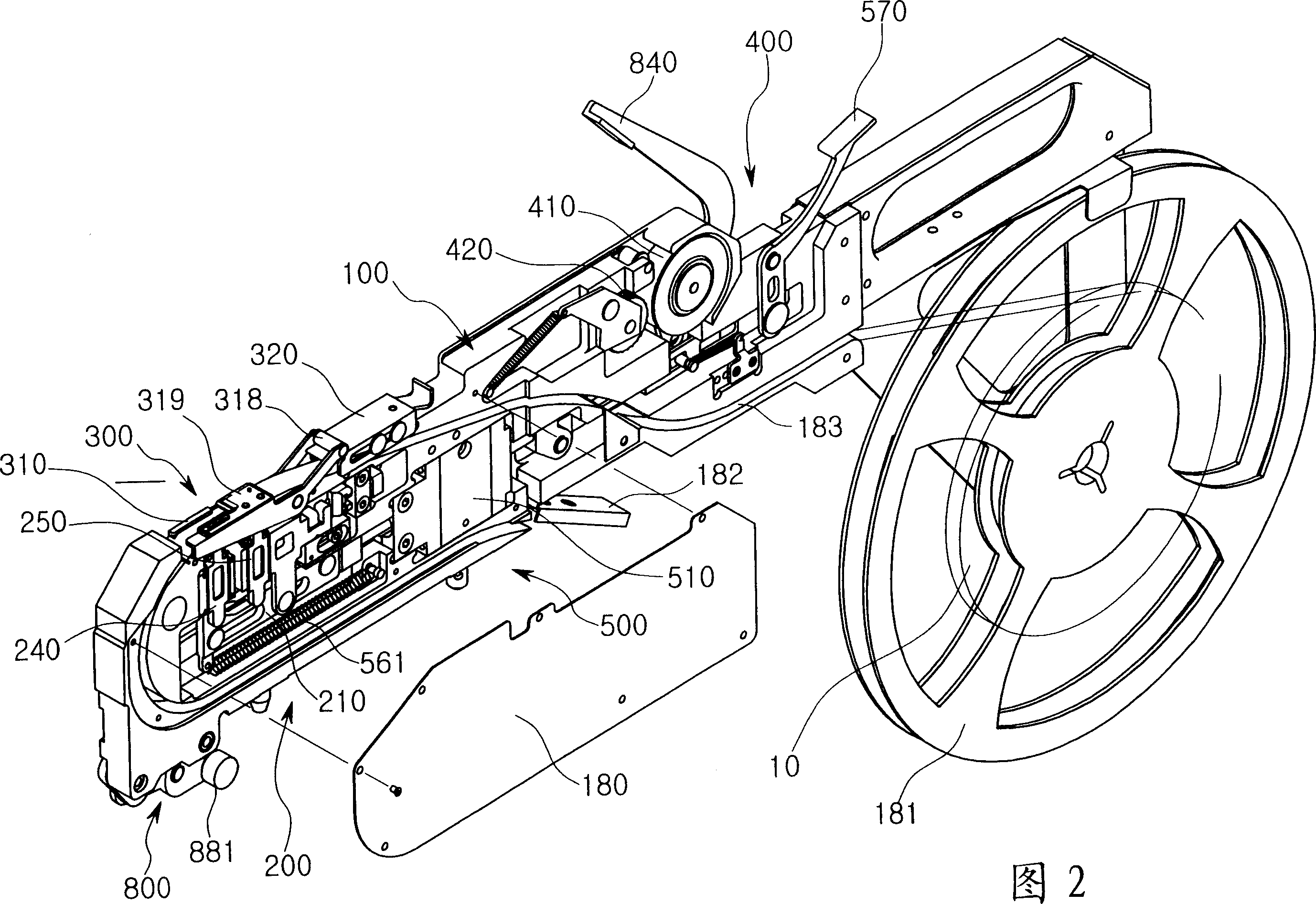

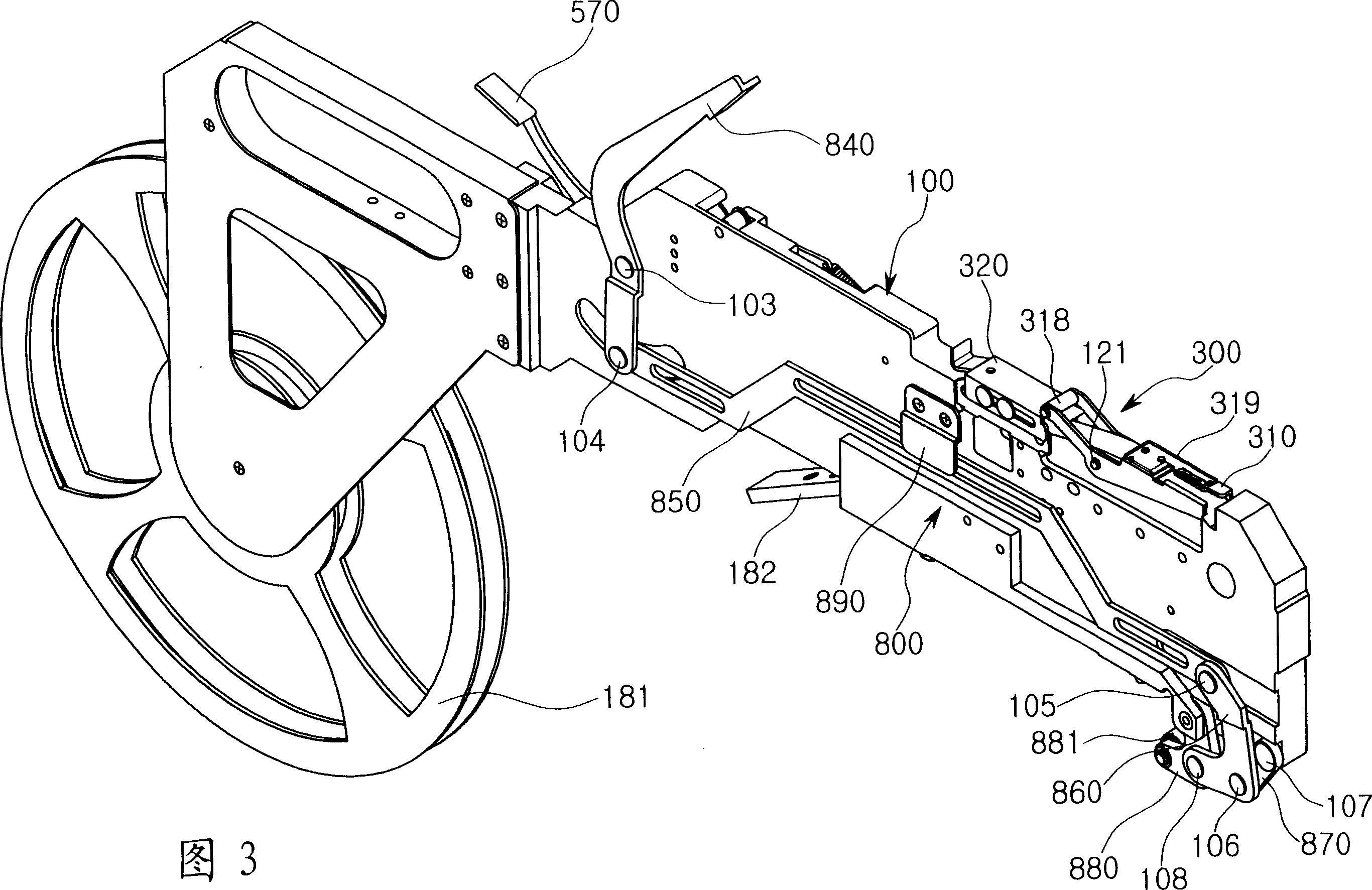

[0039] Below, the structure of the present invention will be described in detail in conjunction with the accompanying drawings.

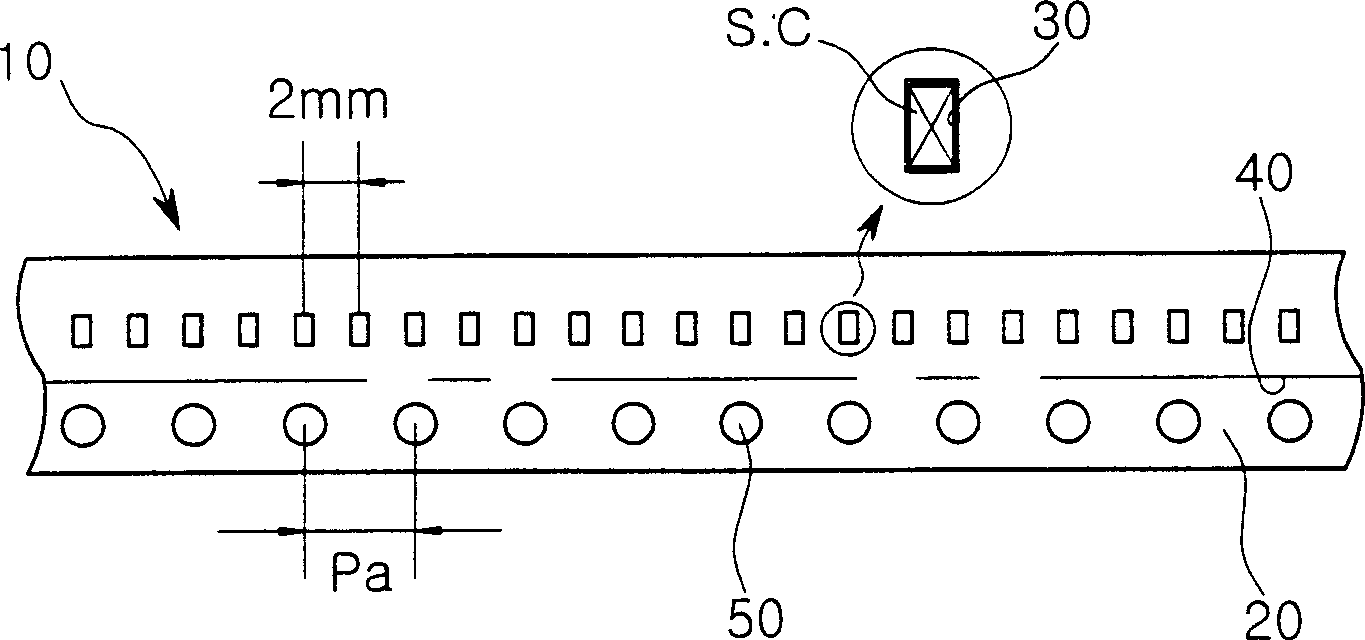

[0040] The tape feeder for the component mounting machine of the present invention, as shown in FIGS. 2 to 15, is composed of a part that transfers and supplies the conveyor belt at a constant interval to the front of the machine body 100 mounted on the normal component mounting machine. The belt transfer mechanism 200 of 10; the door-shaped mechanism 300 provided for the installation and transfer support of the above-mentioned conveyor belt 10; a pair of first and second plastic covers 40 that hold the plastic cover 40 removed from the above-mentioned conveyor belt 10 and discharge it. 2 Plastic cover discharge mechanism 400 for discharge gears 410, 420; drive mechanism 500 for driving at least one discharge gear of the pair of discharge gears 410, 420 and belt transfer mechanism 200 at the same time. Wherein, the above-mentioned belt transfer mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com