Disinfestation light capable of clering away insects automatically

An insect-killing lamp and automatic cleaning technology, which is applied to the field of insect-killing equipment using spectral insect traps, can solve the problems of low insect-killing efficiency, labor-intensive, affecting the high-pressure killing effect, etc., so as to save manpower and improve insecticidal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

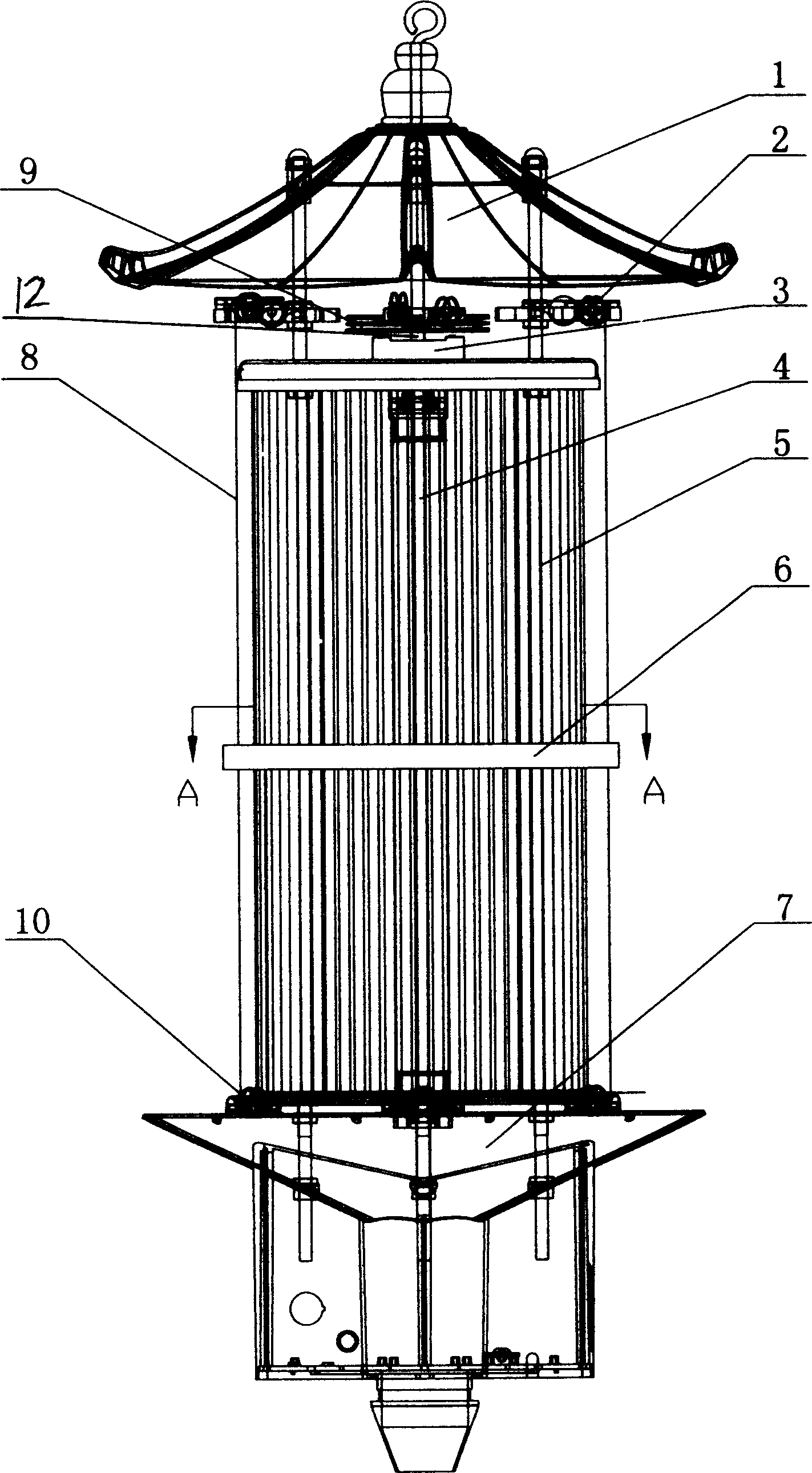

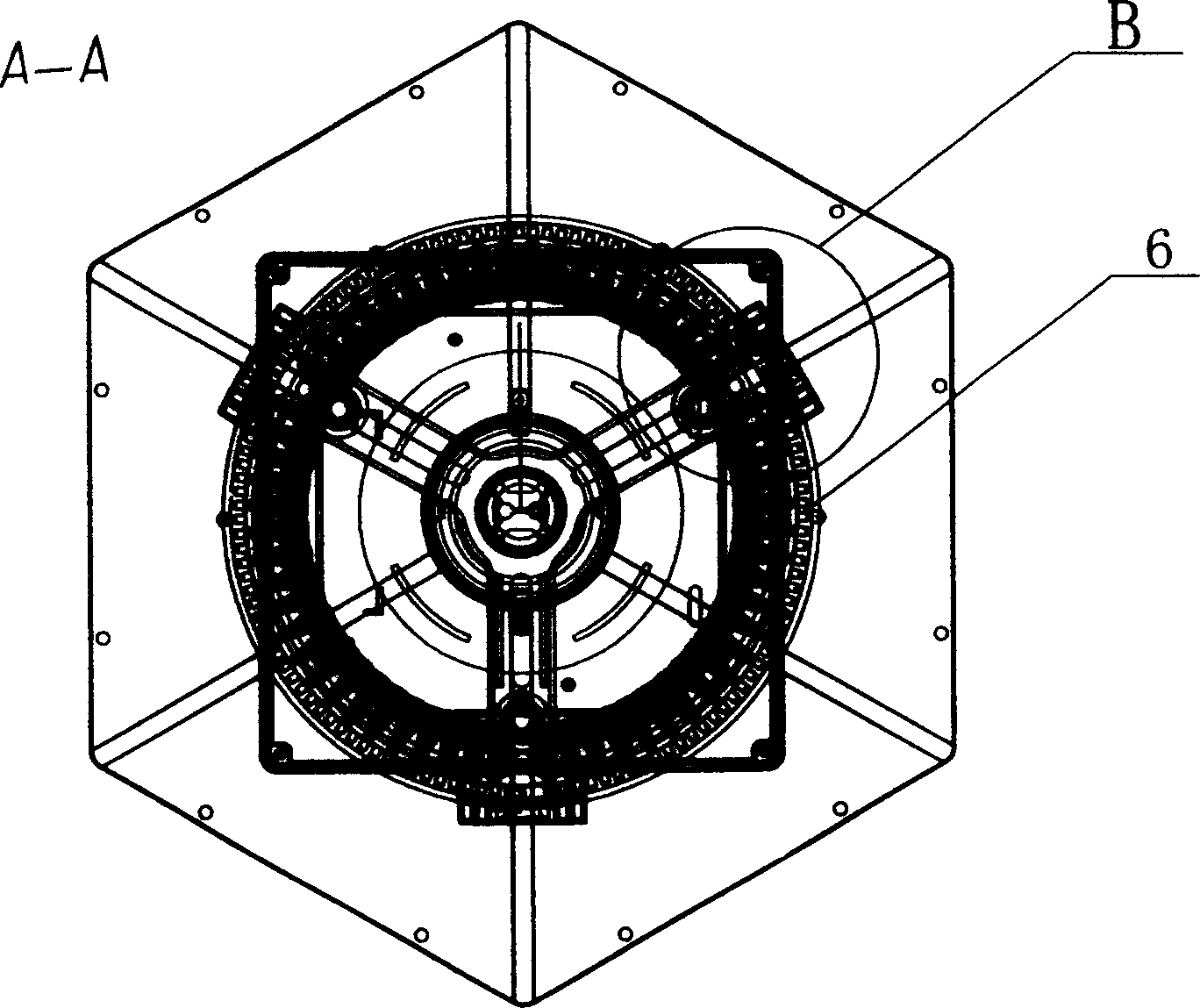

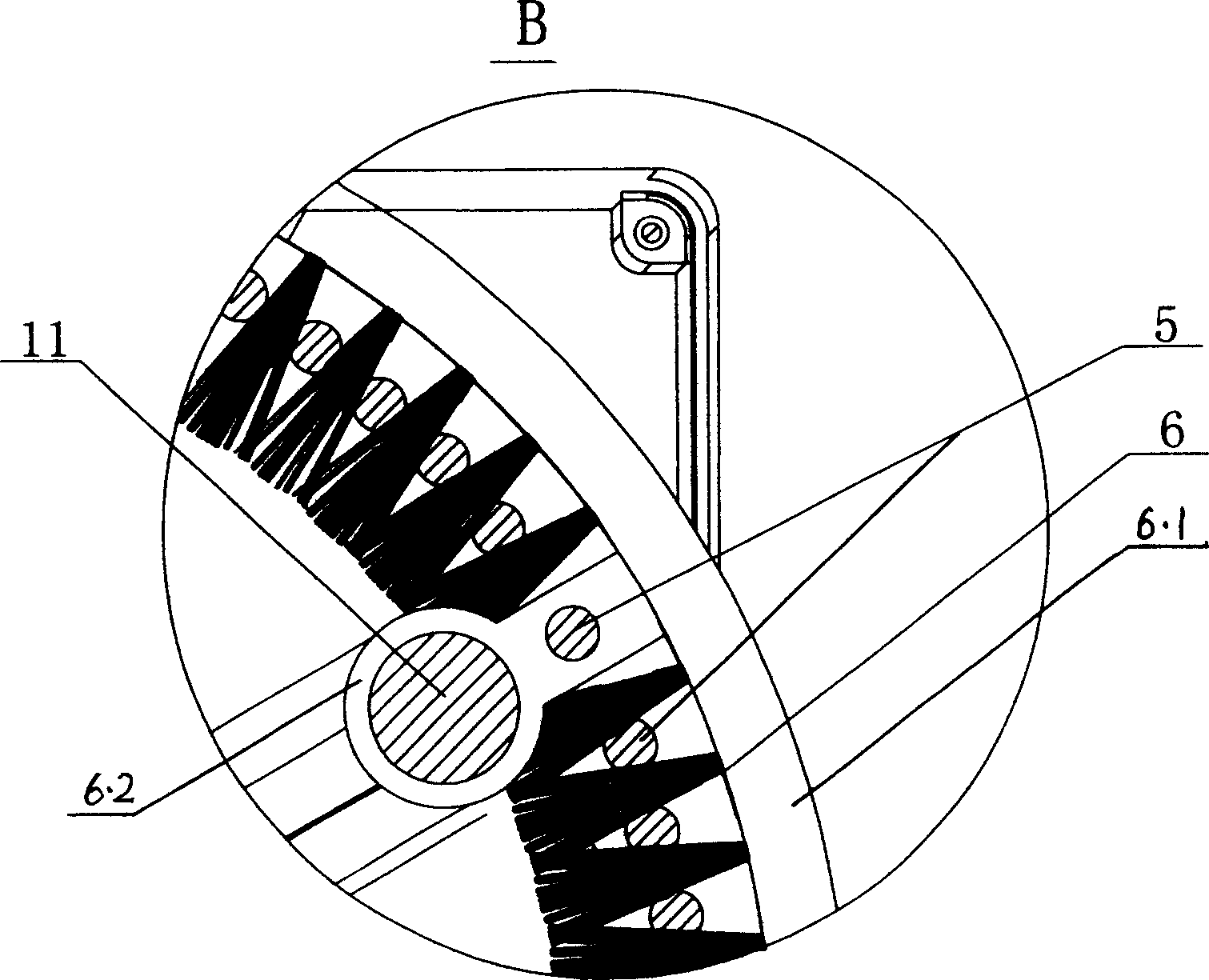

[0009] Lamp tube 4 is installed vertically under the lamp cap 1, and there is a cylindrical high-voltage grid 5 with positive and negative high-voltage lines arranged in sequence around the lamp tube 4, and a ring-shaped brush 6 is installed on the outside of the grid, and the bristles on the brush holder 6.1 stick to each high-voltage wire inward . Both the high voltage grid 5 and the lamp tube 4 are installed between the upper end of the bracket and the base 7 . The two ends of stay cord 8 are fixed on the hairbrush 6 respectively. There are 3 upper and lower pulleys 2 and 10 respectively, which are distributed in an equilateral triangle, and each corresponding pulley up and down constitutes a pulley block respectively.

[0010] Three guide pillars 11 parallel to the high-voltage wires are arranged in the cylindrical high-voltage grid 5, and each guide pillar cover 6.2 protruding laterally from the inner wall of the annular brush holder 6.1 is matched with each guide pillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com