A ring automatic welding device with a protective cover for easy unloading

An automatic welding and protective cover technology, which is applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of many welding points and difficult welding of circular contact surfaces, so as to reduce welding time and facilitate timely automatic removal and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

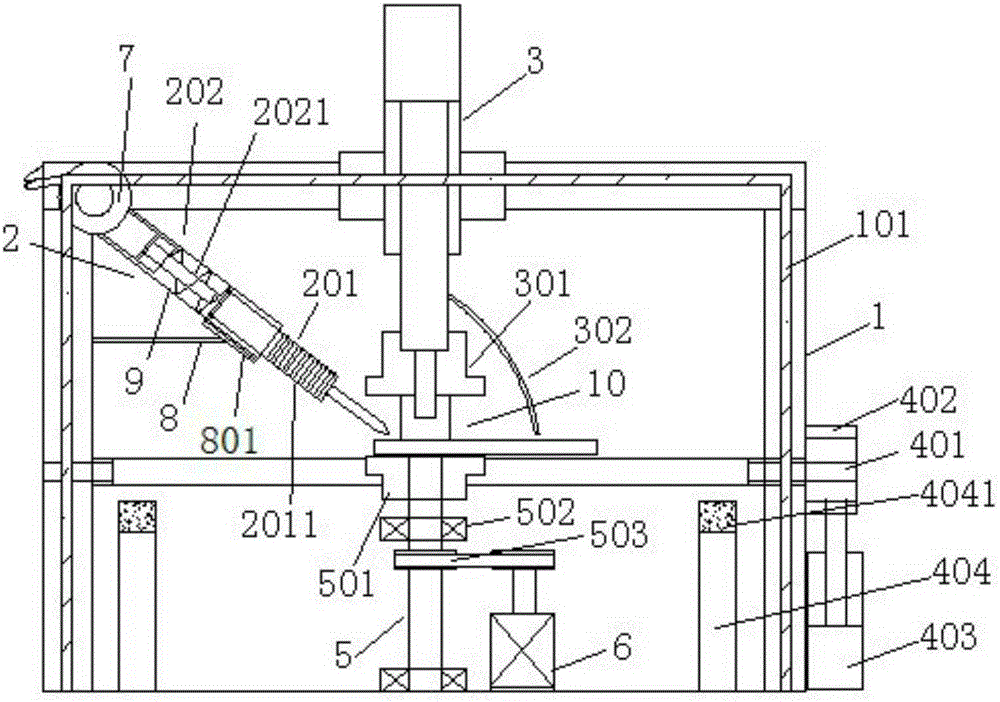

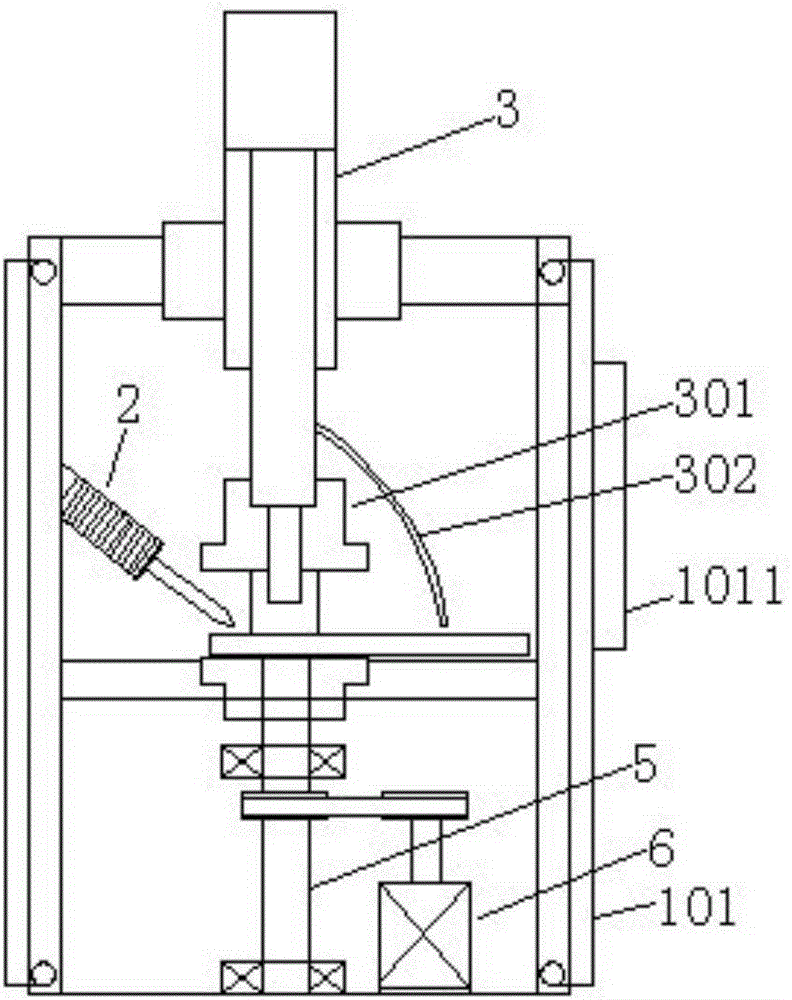

[0014] See attached figure 1 , 2 , a ring automatic welding device with a protective cover for easy unloading, comprising a fixed frame 1 and a welding machine 2, the welding machine 2 is arranged on the fixed frame 1, and a positioning cylinder 3 is provided at the middle position of the upper end of the fixed frame 1, and the positioning A material receiving plane 4 is provided below the cylinder 3, and the two ends of the material receiving plane are rotated on the fixed frame through the first rotating shaft 401, and one end extends to the outside of the fixed frame to be provided with a rotating tooth plate 402, which is connected to the pushing cylinder 403 , There is a supporting column 404 under the four corners of the material receiving plane, and the upper part of the supporting column has a rubber cushion 4041, which is convenient for supporting the material receiving plane 4 after rotation. A second rotating shaft 5 is provided below the material receiving plane 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com