Automatic dust removal method and device for protective net of strong ventilation device

A technology of strong ventilation and automatic dust removal, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve problems such as affecting ventilation and heat dissipation efficiency, affecting work efficiency and equipment operation, increasing power consumption, etc. , to reduce the workload of manual maintenance and cleaning, improve the efficiency of ventilation and heat dissipation, and achieve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

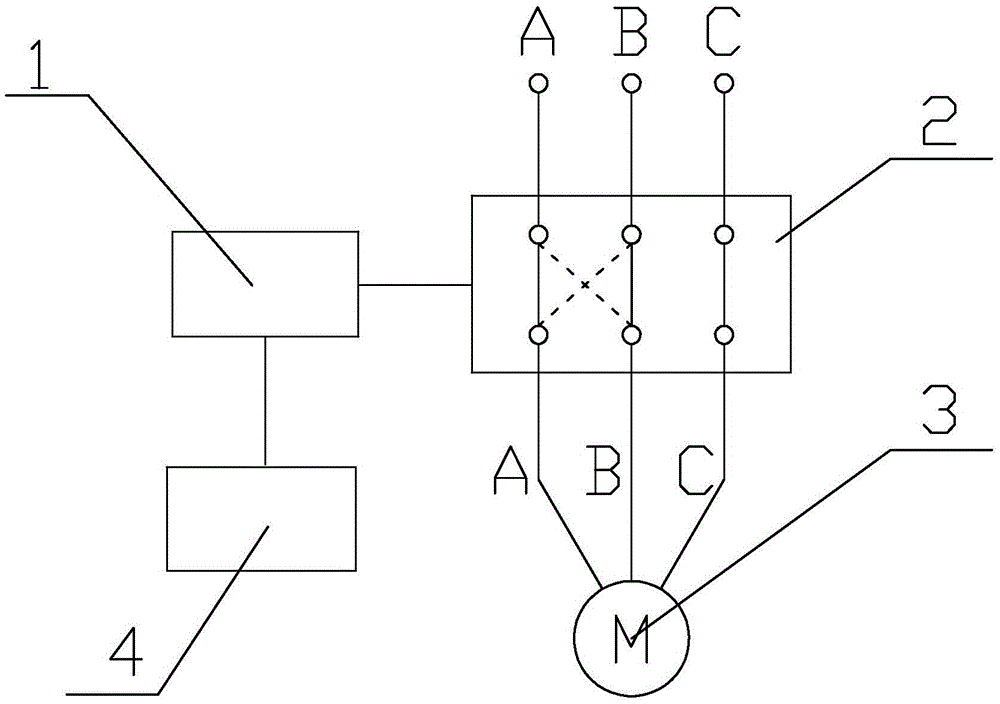

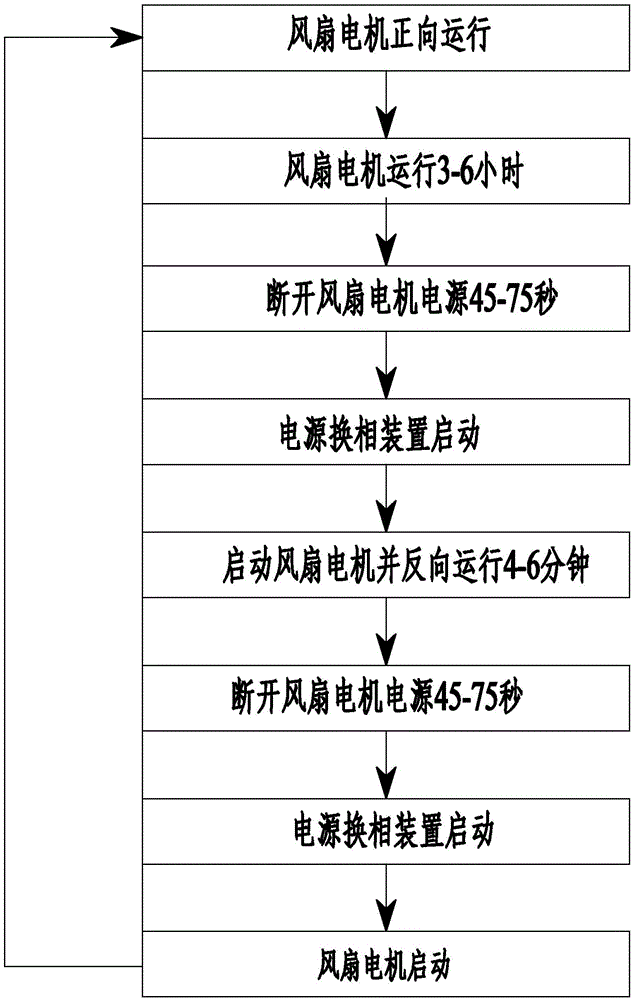

[0024] Such as figure 1 As shown, the automatic dust removal method for the protective net of the forced ventilation device described in this embodiment is that a power commutation device is connected in series in the power circuit of the fan motor 3 of the forced ventilation device, and the power supply of the fan motor 3 is changed by the power commutation device 2. The phase sequence of the fan motor 3 can be reversed, and then the direction of its blowing can be changed, and the dirt, dust and sundries adsorbed on the protective net will be blown away; the signal output terminal of the programmable logic controller 1 and the power commutation device 2 connected, connect the signal input terminal of the programmable logic controller 1 to the man-machine interface 4, and pre-set the time interval and forward and reverse operation of the power supply of the fan motor 3 through the man-machine interface 4 and the programmable logic controller 1 The running time can not only en...

Embodiment 2

[0032] In this embodiment, on the basis of Embodiment 1, the power commutator is replaced by two parallel AC contactors, so as to realize the switching of the forward and reverse rotation of the fan motor 3 . The other structures of this embodiment are exactly the same as those of Embodiment 1.

Embodiment 3

[0034] The automatic dedusting device of embodiment 1 described in the present embodiment includes a strong ventilation device for industrial workshops, the strong ventilation device is provided with a fan motor 3 and a protective net, and the fan motor 3 three-phase power supply input terminal is connected with the power supply commutation device 2 three-phase The output terminals are connected, the three-phase input terminal of the power commutation device 2 is connected to the power supply, the signal output terminal of the programmable logic controller 1 is connected to the signal input terminal of the power commutation device 2, and the signal input terminal of the programmable logic controller 1 is connected to the signal input terminal of the power commutation device 2. The man-machine interface 4 is connected.

[0035] Among them, the man-machine interface 4 adopts a touch screen, which can directly set the time interval of the power commutation operation of the fan mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com