Automatic assembling machine for big fransfusion bottle cover

A fully automatic, large-scale infusion technology, used in transportation and packaging, bottle/container caps, packaging, etc., can solve problems such as pollution, low production efficiency, lower product quality and civilized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

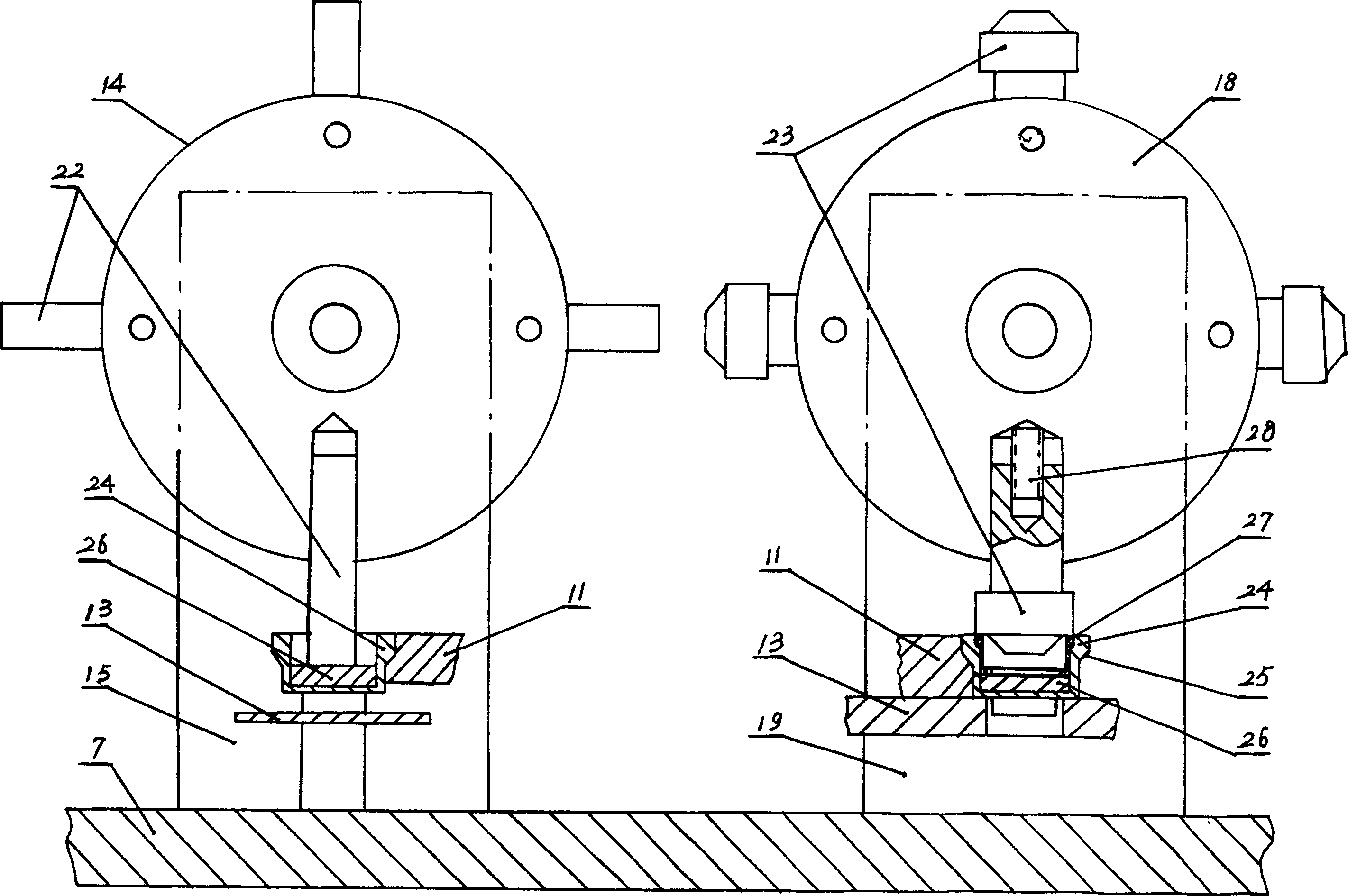

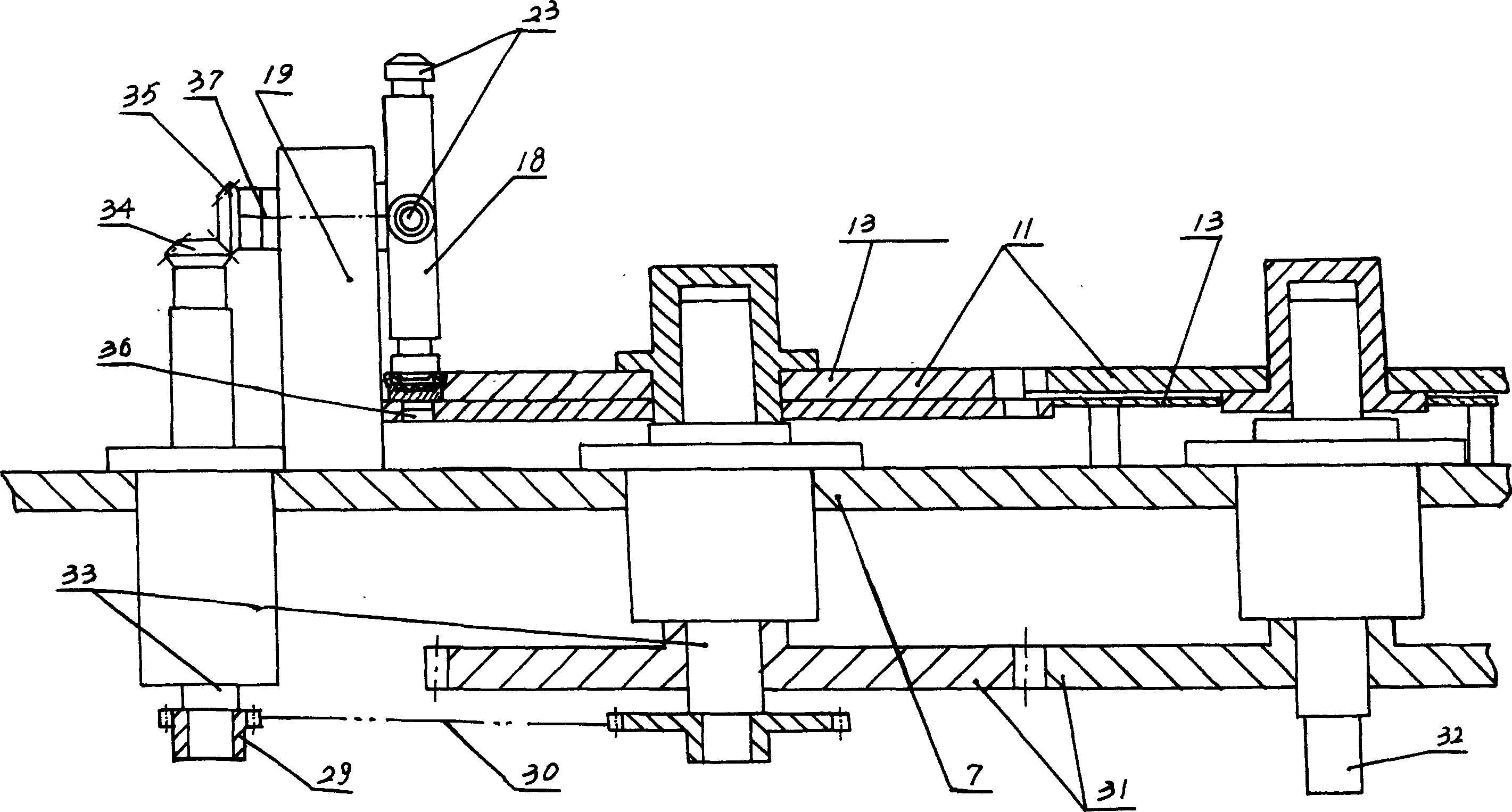

[0008] The invention discloses a full-automatic assembling machine for large transfusion bottle caps, which is mainly used for fully automatic assembly of large transfusion plastic bottle caps for polymer medicine packaging. The fully automatic assembly machine consists of a frame and a power and transmission mechanism installed in the frame. The transmission mechanism drives the feeding device, and the feeding device cooperates with the pressing device. The main part of the feeding device is the feeding group, generally three A material shifting group that cooperates with each other, but it can also be two material shifting groups, each dialing group has a rotating shaft (including the main transmission shaft 32 and the rotating shaft 33) to drive the rotating dial 11, and there is a support below the dial. Plate 13, for dial 11 and supporting plate 13, can be split (two pieces) or made in one piece, the periphery of dial 11 is shaped on dial tooth 12, and supporting plate 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com