Static microactuator with electric insulative movable portion and related driving circuit

A technology of actuators and electrical insulating materials, applied in the directions of electrostatic generators/motors, generators/motors, driving/moving recording heads, etc., which can solve the problems of increasing noise by magnetic signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

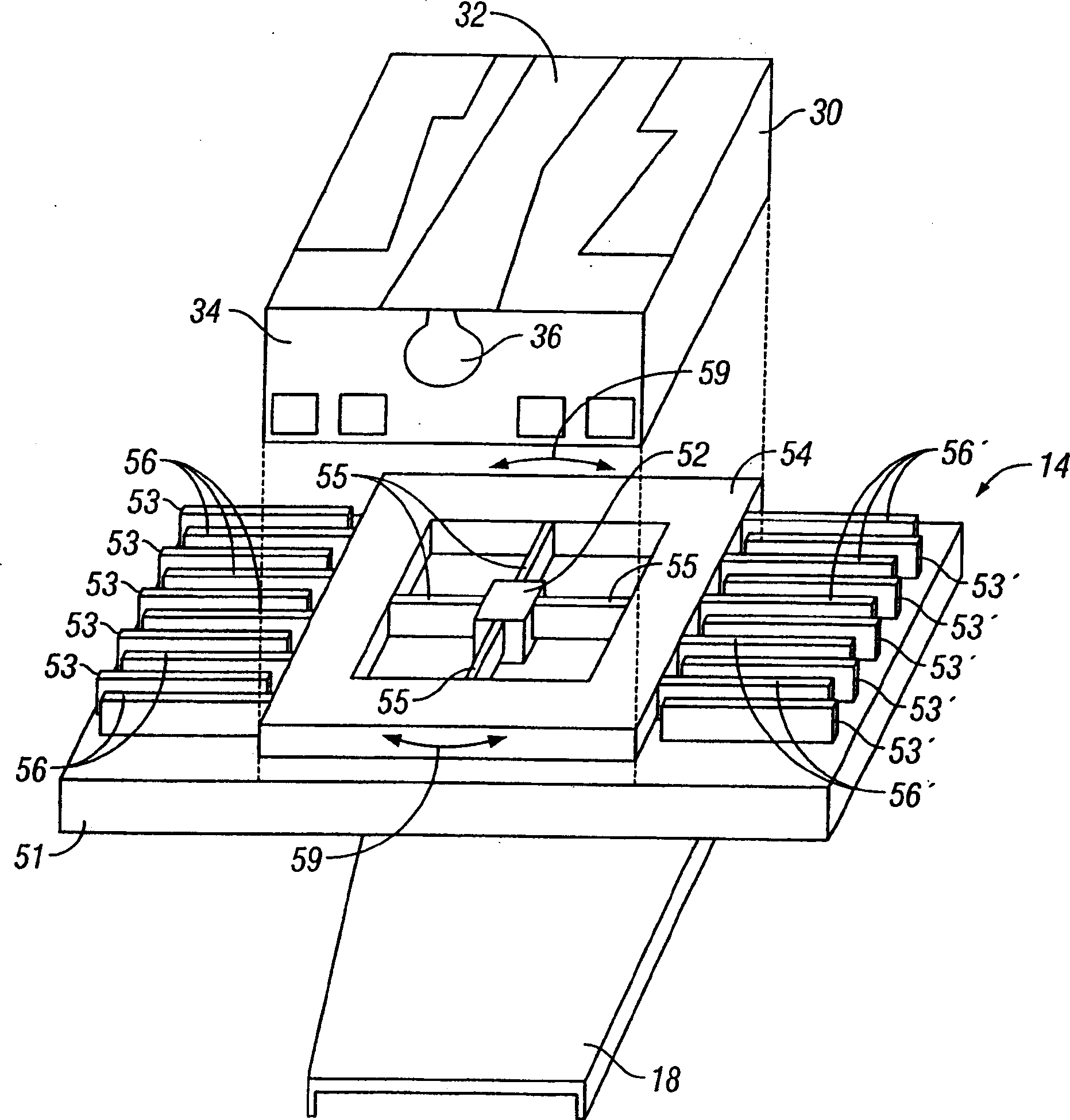

[0025]FIG. 6 shows the microactuator 114 and its driving circuit of the present invention. Microactuator 114 has a movable frame 140 that includes a generally rectangular interior 141 and exterior 142 formed from a conductive metal, typically nickel. The two frame parts 141 and 142 are connected together but are electrically isolated from each other by an electrically insulating material 143 . The frame 140 has two opposing side walls 145, 147, each of which faces a respective set of fixed electrode branches 153, 153' spaced apart on the substrate 151 . The outer portion 142 of the frame 140 also has side walls 161, 163 which support respective sets of movable electrode branches 156, 156'. Walls 161 , 145 , and walls 163 , 147 are connected by insulating material 143 . Figure 7 is a partial view of FIG. 6 (without the optional bonding platform connected to the interior 141 of the frame 140), which more clearly shows how the slider is electrically isolated from the movable el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com