Self-learning method of shifting force of double clutch automatic transmission fork

A technology of automatic transmission and self-learning method, which is applied in the field of self-learning of shifting fork of dual-clutch automatic transmission, can solve the problems affecting the service life of the shifting fork, the service life of the synchronizer, and the increase of shifting noise, so as to avoid Effects of noise, reduced power consumption, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

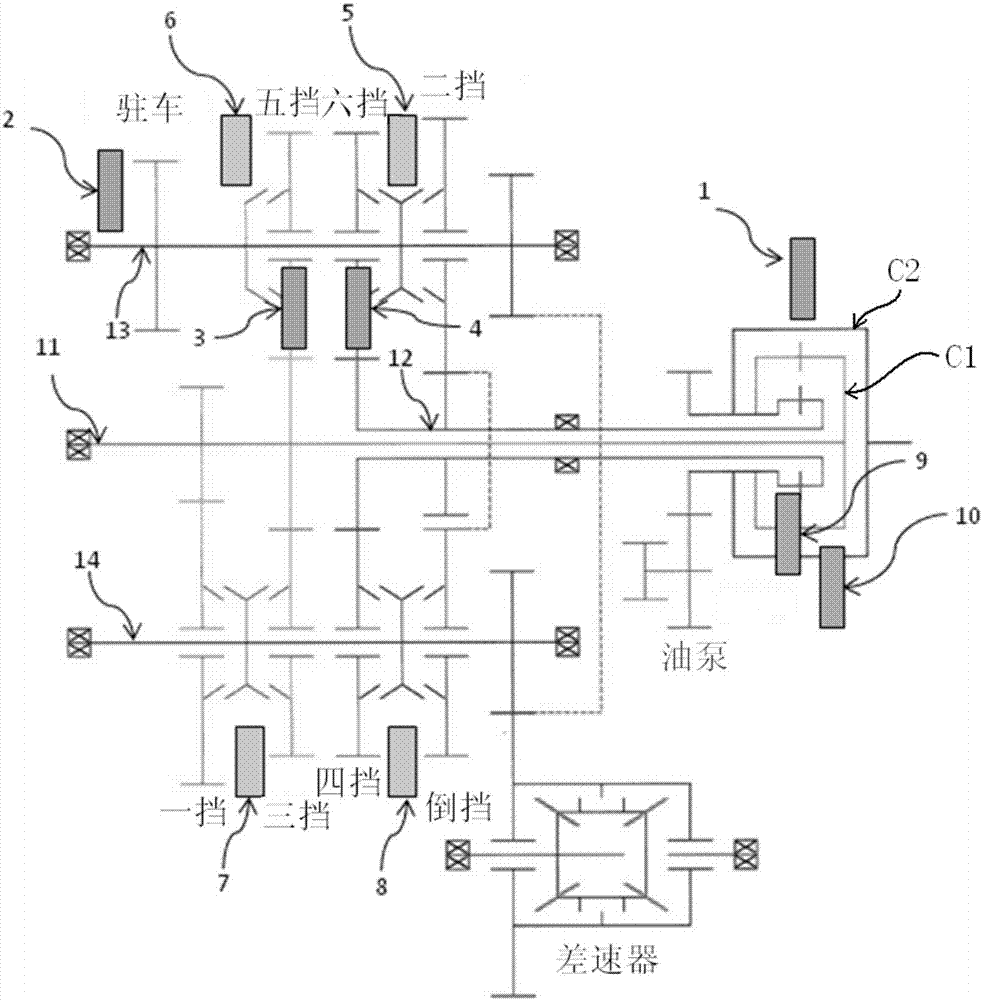

[0025] The embodiments described next are combined figure 1 However, those skilled in the art should note that the embodiments of the present invention are not limited to the specific dual-clutch automatic transmission with the above-mentioned structure, and the above-mentioned gears, synchronizers, output shafts and other devices The number and arrangement of can be increased, decreased, and changed without departing from the scope of the essential concept of the present invention.

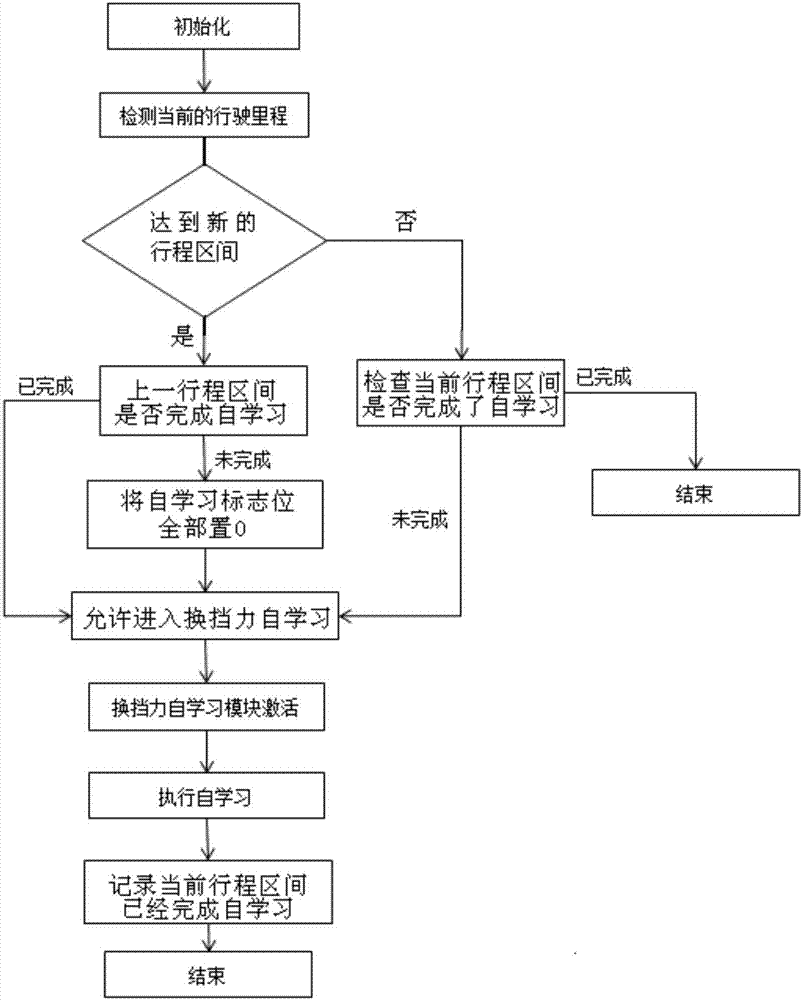

[0026] refer to figure 2 , when the TCU (transmission control unit) is powered on, it will initialize the software to detect the current mileage. In this embodiment, the mileage is divided into different travel intervals. The travel interval refers to a calibrated design value, such as 500Km, or 1000Km. Different values will be set according to different hardware systems, such as 500Km. If there is one travel section, when it is detected that the current mileage is 1300Km, it means that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com