Mould processing order arranging system and method

A mold processing and mold technology, applied in the system field of the main production scheduling, can solve the problems of the quality impact of the allocation, and achieve the effect of improving the utilization rate and shortening the mold delivery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

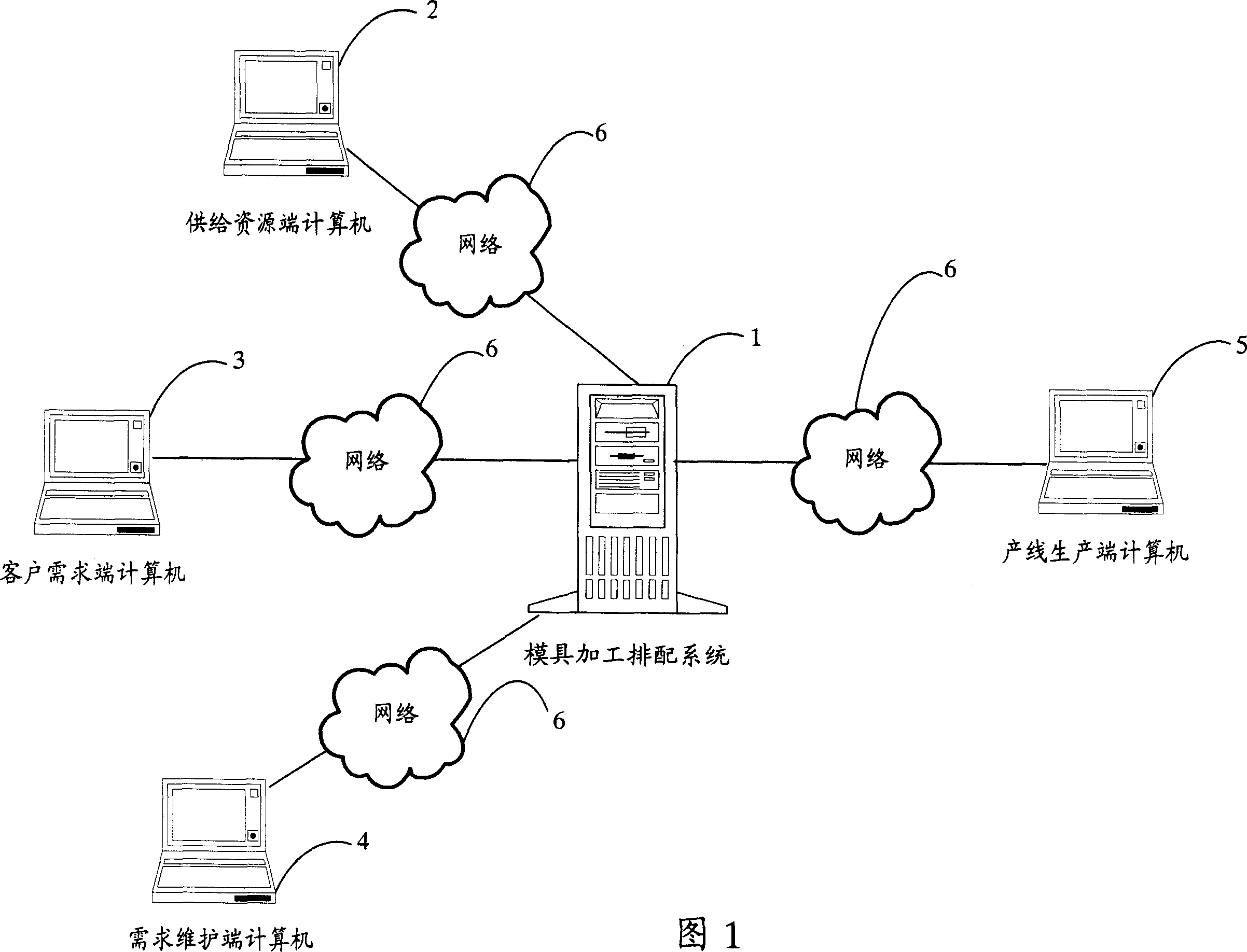

[0018] Refer to FIG. 1, which is a diagram of the network computer system architecture of the mold processing and arranging system and method of the present invention. It consists of a distributed supply side computer 2, a customer demand side computer 3, a demand maintenance side computer 4, and a production line production side computer 5 connected to a mold processing and scheduling system 1 through a network 6. Among them, the network 6 is an electronic network, which can be an intranet, an Internet, or other types of networks. In the present invention, the source computer 2, the customer demand computer 3, the demand maintenance computer 4, and the production line production computer 5 can be Windows 95, Windows 98 or Windows NT user environments, and the above terminal computers are of various types The user provides an interactive user interface. Among them, enterprise employees can input the basic information of the machine resources owned by the enterprise that can provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com