Exhaust gas quide structure of closed compressor

A guide structure and compressor technology, applied in mechanical equipment, machines/engines, rotary piston machinery, etc., can solve problems such as increasing the input power and eccentric torque of the electric mechanism, hindering the discharge of compressed gas, and extending the rotating shaft. Achieve the effects of reducing vibration and noise, reducing production costs, and reducing input power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

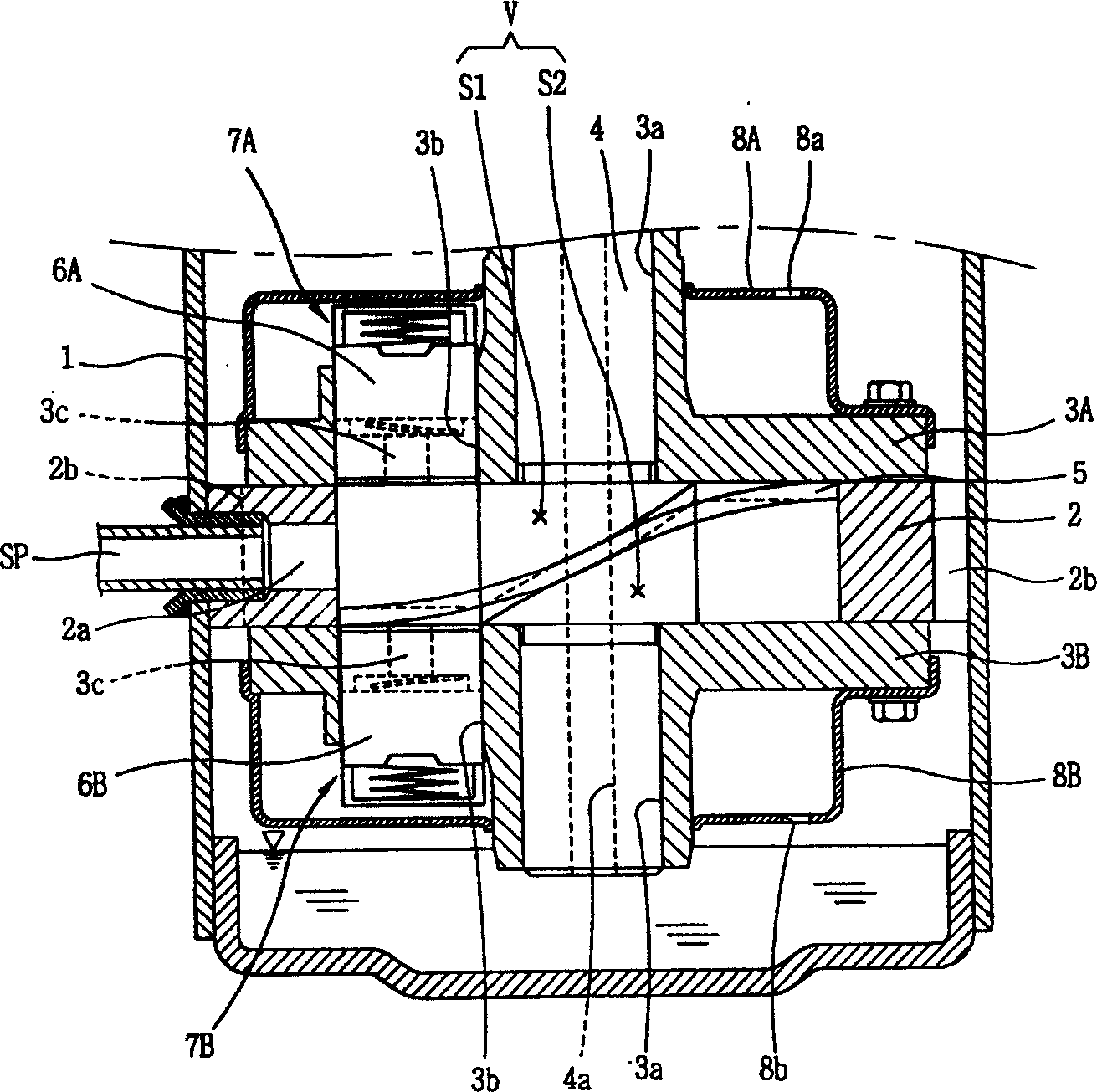

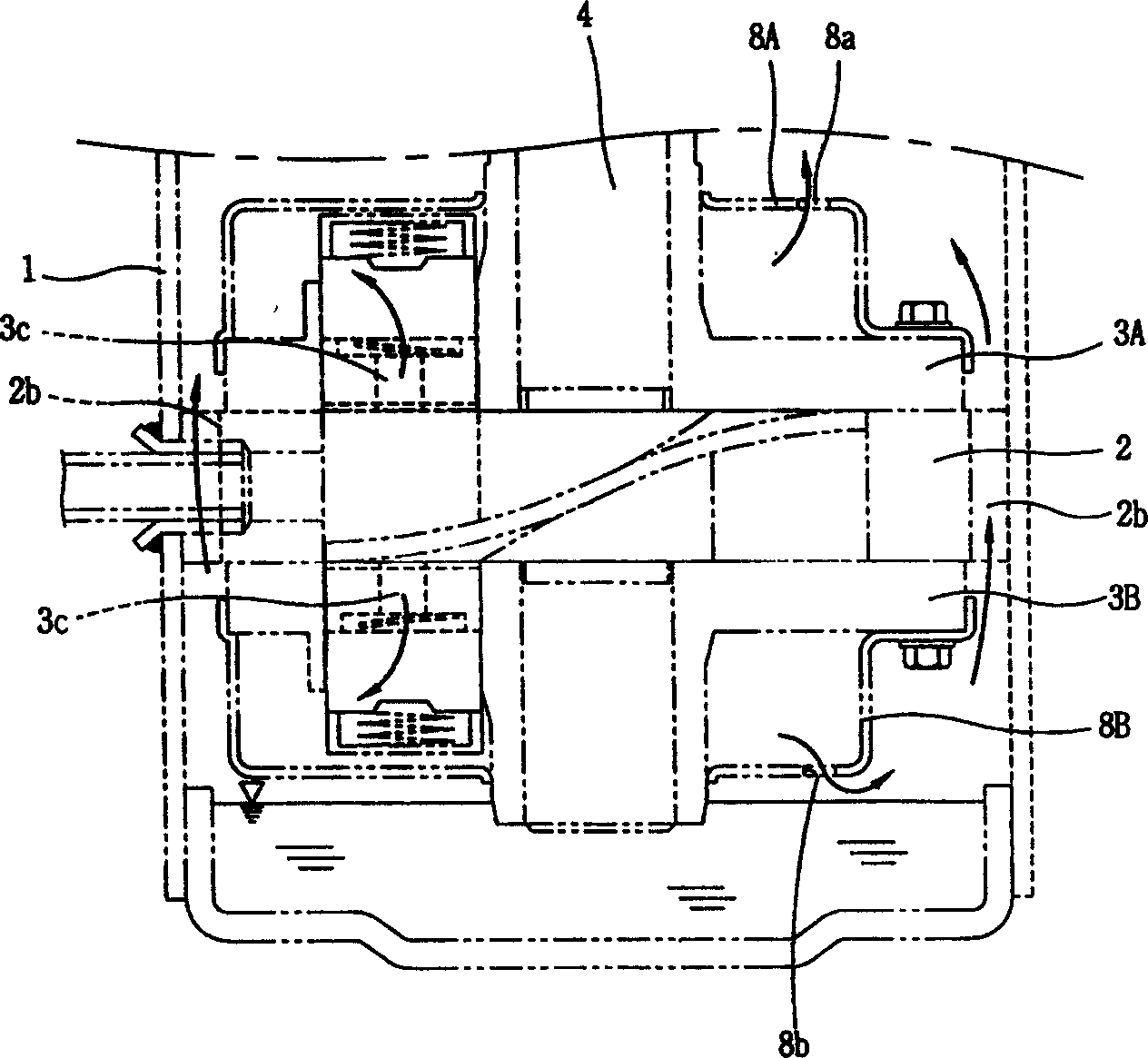

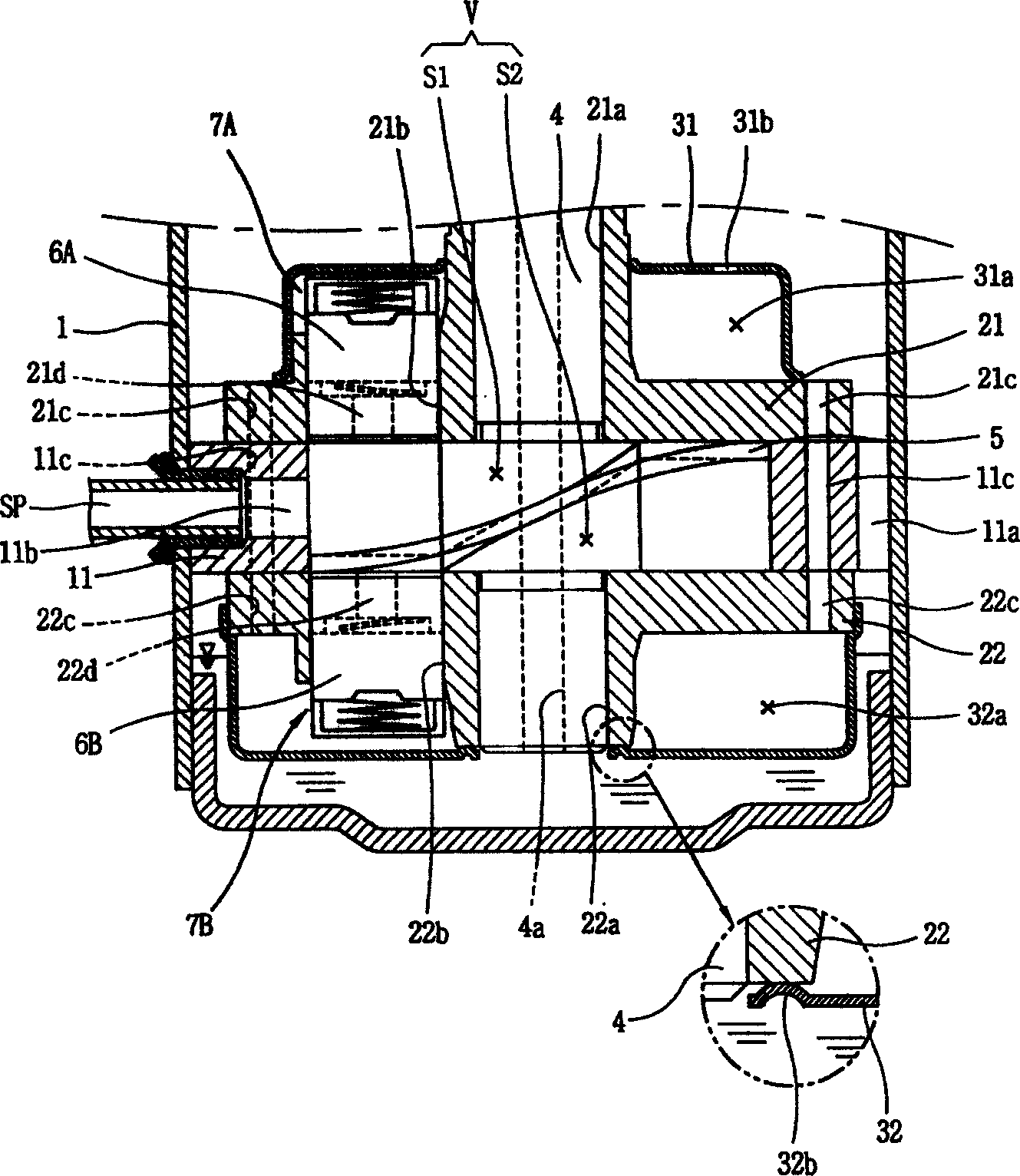

[0039] Such as image 3 and Figure 4 As shown, the hermetic compressor applicable to the exhaust guide structure of the hermetic compressor of the present invention includes: a casing 1, a cylinder 11, a partition plate 5, a rotating shaft 4, a first guide plate 6A, a second guide plate 6B, and an upper bearing Plate 21, lower bearing plate 22, upper muffler 31 and lower muffler 32; a certain amount of oil is installed at the bottom of the cavity of the shell 1; the cylinder 11 is fixedly installed on the upper half of the cavity of the shell 1, On the side wall of the cylinder 11, an air intake 11b connected with the internal space V of the cylinder 11 is formed; the rotating shaft 4 is connected with the rotor (not shown) of the electric mechanism; the division plate 5 connects the cylinder The internal space V of 11 is divided into a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com