Induction heating roller device for use in image forming apparatus

A technology of induction heating and heating roller, which is applied in the direction of induction heating, electric recording process equipment using charge graphics, induction heating devices, etc., and can solve problems such as wrong actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] In the drawings, like numbers are used for like elements. The present invention will be described below with reference to the accompanying drawings.

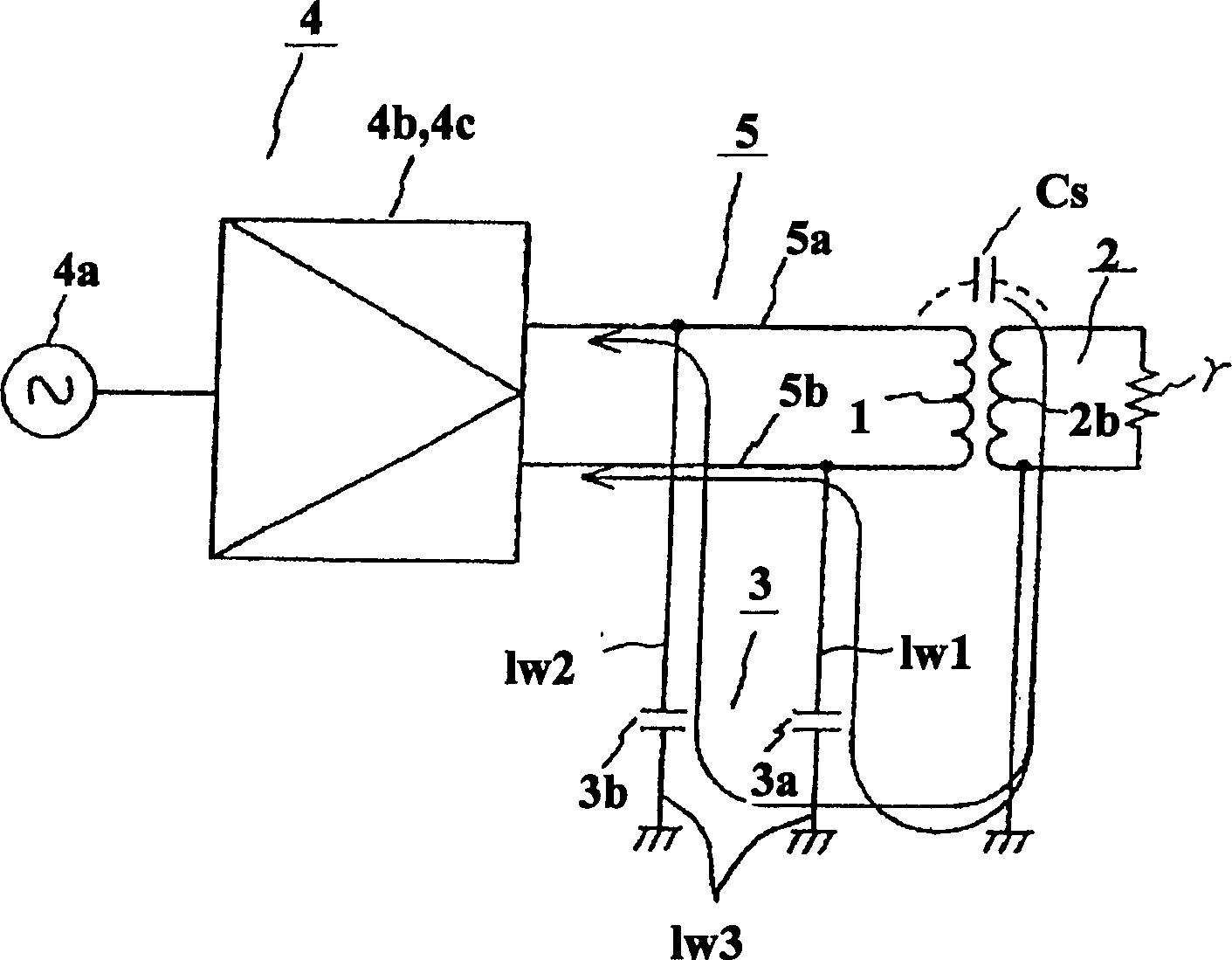

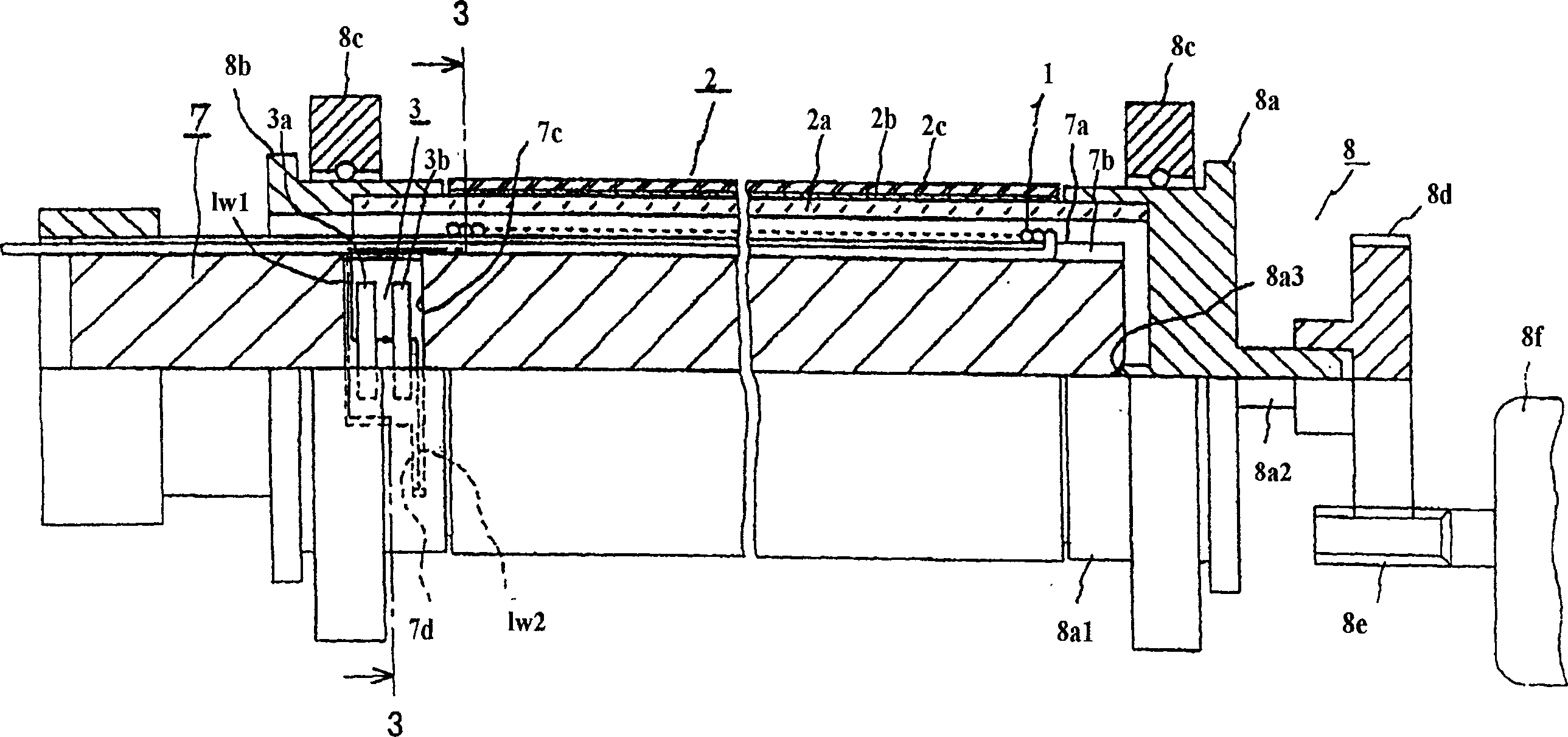

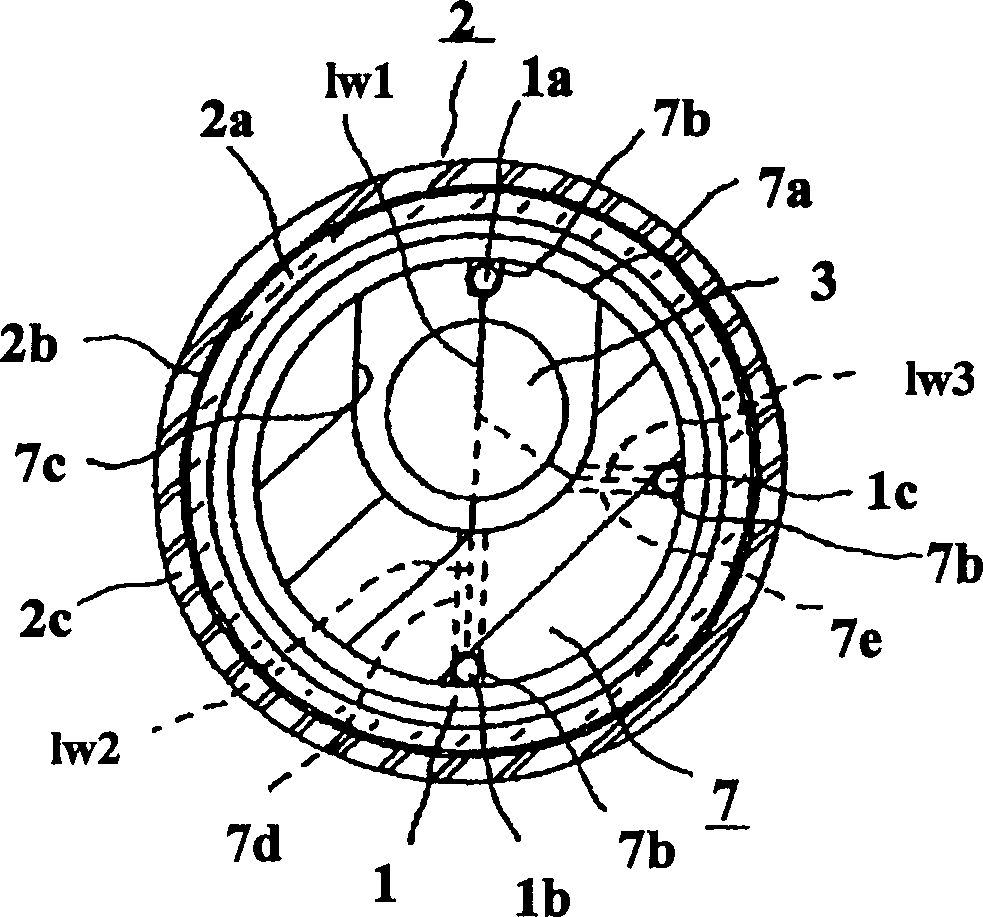

[0089] figure 1 and 4 is a schematic circuit diagram of the induction heating roller apparatus according to the first embodiment of the present invention. figure 2 is a cross-sectional view of the induction coil and heating roller. image 3 is a cross-sectional view along line 3-3. Figure 4 is the circuit diagram of the high frequency power supply and matching circuit.

[0090] In this embodiment, the induction coil device includes an induction coil 1 , a heating roller 2 , a power factor improving capacitor 3 , a high frequency power supply 4 , a high frequency transmission line 5 , a matching circuit 6 , a coil tube 7 , and a rotating mechanism 8 . Each element will be described below.

[0091] [Induction coil 1]

[0092] refer to figure 2 and 3 , the induction coil 1 is wound on the coil former 7 and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com